A lead-free high energy storage density high energy storage efficiency ceramic dielectric material and preparation method thereof

A technology of high energy storage density and ceramic medium, applied in the field of dielectric energy storage ceramic materials, can solve the problems of low energy storage density and limited application of materials, and achieve the effects of good energy storage performance, increased breakdown strength, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

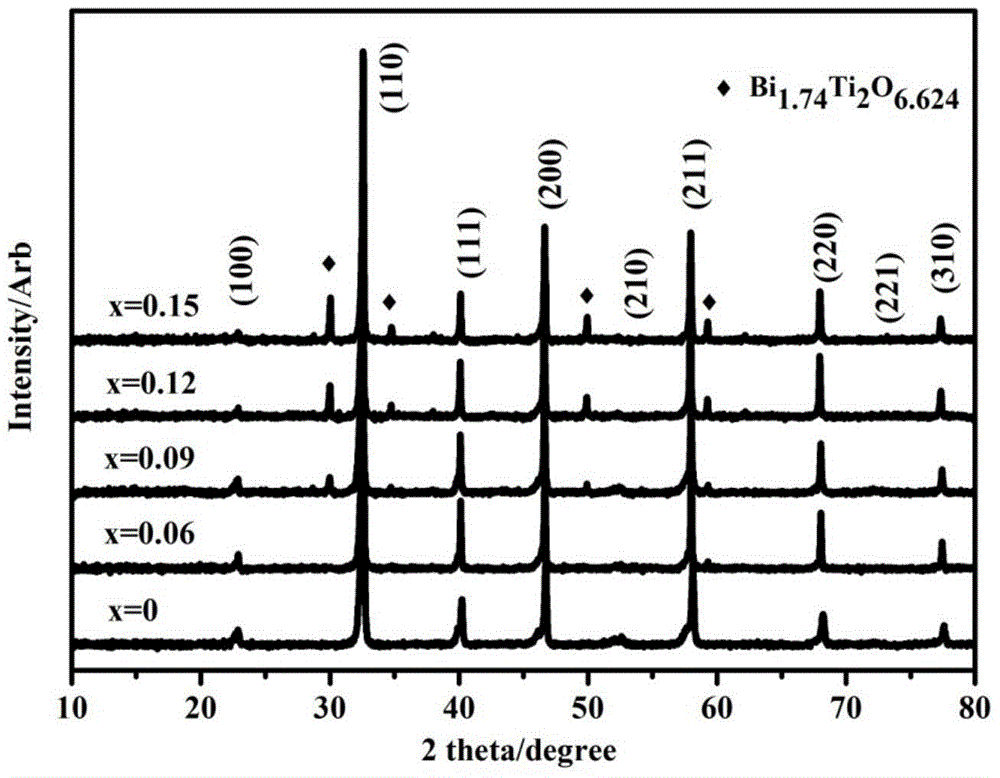

[0050] A lead-free ceramic dielectric material with high energy storage density and high energy storage efficiency, the chemical formula is 0.94[0.84(Bi 0.5 Na 0.5 )TiO 3 -0.16 (Bi 0.5 K 0.5 )TiO 3 ]-0.06K 0.5 Na 0.5 NbO 3 .

[0051] The above-mentioned preparation method of lead-free high energy storage density and high energy storage efficiency energy storage medium ceramics, the steps are as follows:

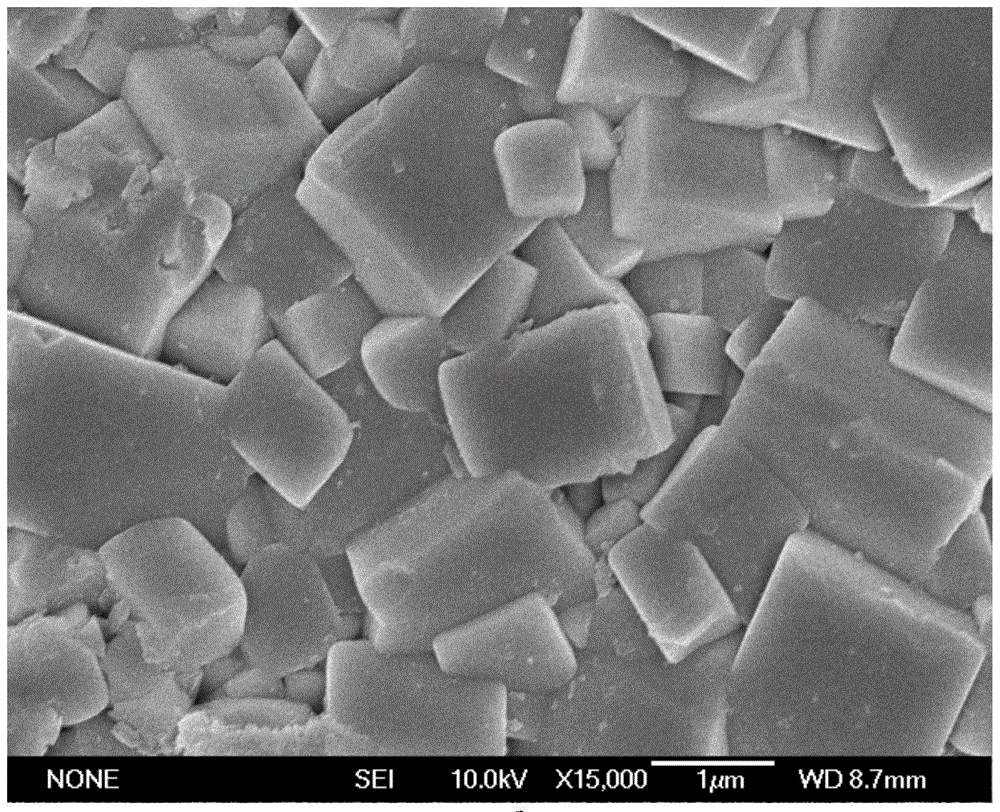

[0052] (1) According to the molar ratio, it is Na 2 CO 3 :K 2 CO 3 : Bi 2 O 3 : TiO 2 : Nb 2 O 5 = 0.2124:0.0526:0.235:0.94:0.03 (x=0.06) proportion of ingredients, put the prepared raw materials into the ball mill, zirconia balls and anhydrous ethanol as the medium, mix the ball mill for 26 hours and mix well, after drying The ceramic powder is obtained by pre-calcining in a medium-temperature furnace. The pre-calcining process is to raise the temperature to 900 °C at a heating rate of 2 °C / min at room temperature, keep the temperature for 2 hours, and then ...

Embodiment 2

[0058] A lead-free ceramic dielectric material with high energy storage density and high energy storage efficiency, the chemical formula is 0.91[0.84(Bi 0.5 Na 0.5 )TiO 3 -0.16 (Bi 0.5 K 0.5 )TiO 3 ]-0.09K 0.5 Na 0.5 NbO 3 .

[0059] The above-mentioned preparation method of lead-free high energy storage density and high energy storage efficiency energy storage medium ceramics, the steps are as follows:

[0060] (1) According to the molar ratio, it is Na 2 CO 3 :K 2 CO 3 : Bi 2 O 3 : TiO 2 : Nb2 o 5 =0.2136:0.0589:0.2275:0.91:0.045 (x=0.09) ratio ingredients, put the prepared raw materials into the ball mill, zirconia balls and absolute ethanol as the medium, mix the ball mill for 22 hours and mix evenly, after drying Place it in a medium-temperature furnace for pre-calcination to obtain ceramic powder. The pre-calcination process is to raise the temperature to 850 °C at a rate of 2 °C / min at room temperature, keep it for 2 hours, and cool naturally with the fu...

Embodiment 3

[0066] A lead-free ceramic dielectric material with high energy storage density and high energy storage efficiency, the chemical formula is 0.88[0.84(Bi 0.5 Na 0.5 )TiO 3 -0.16 (Bi 0.5 K 0.5 )TiO 3 ]-0.12K 0.5 Na 0.5 NbO 3 .

[0067] The preparation method of the above lead-free high energy storage density and high energy storage efficiency energy storage medium ceramics, the steps are as follows:

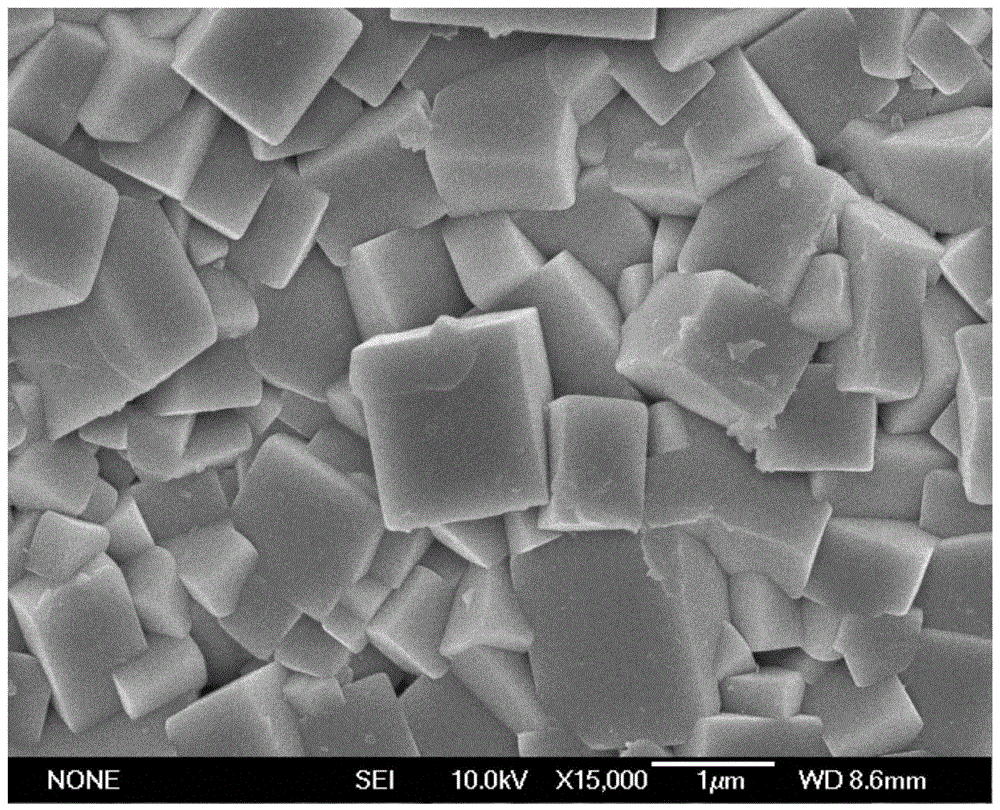

[0068] (1) Na according to the molar ratio 2 CO 3 :K 2 CO 3 : Bi 2 o 3 : TiO 2 : Nb 2 o 5 =0.2148:0.0652:0.22:0.88:0.06 (x=0.12) ratio ingredients, put the prepared raw materials into the ball mill, zirconia balls and absolute ethanol as the medium, mix the ball mill for 26 hours and mix evenly, after drying Place it in a medium-temperature furnace for pre-calcination to obtain ceramic powder. The pre-calcination process is to raise the temperature to 850°C at a rate of 4°C / min at room temperature, keep it warm for 2 hours, and cool naturally with the furnace;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com