A kind of ceramic material with high energy storage performance and ultrafast discharge rate and preparation method thereof

A discharge rate and ceramic material technology, applied in the field of ceramic materials with high energy storage performance and ultra-fast discharge rate and its preparation, can solve the problems of high remnant polarization, low dielectric breakdown field, and obstacles to practical applications , to achieve the effect of improving the dielectric breakdown field strength, high density, and suppressing the remnant polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the ceramic material with high energy storage performance and ultra-fast discharge rate of the present invention comprises the following steps:

[0048] (1) According to the chemical formula (1-x) (Na 0.5 Bi 0.5 ) 0.7 Sr 0.3 TiO 3 -xBi(Mg 2 / 3 Nb 1 / 3 )O 3 Analytically pure SrCO 3 , Na 2 CO 3 , TiO 2 , Bi 2 O 3 , MgO and Nb 2 O 5 The ingredients, where x represents the mole fraction, and 0.05≤x≤0.20, take absolute ethanol as the medium, and mix them uniformly by ball milling for 22 to 24 hours, then dry at 100 ° C, pass through a 120-mesh sieve, briquette, and then pass 800 Pre-sintering at ~900°C for 3-5 hours to obtain block solids, and then crushing the block solids and passing through a 120-mesh sieve to obtain pre-calcined powders;

[0049] (2) using absolute ethanol as a medium for the pre-fired powder obtained in step (1), ball-milling for 22 to 24 hours, then drying at 100° C., and passing through a 120-mesh sieve to obtain...

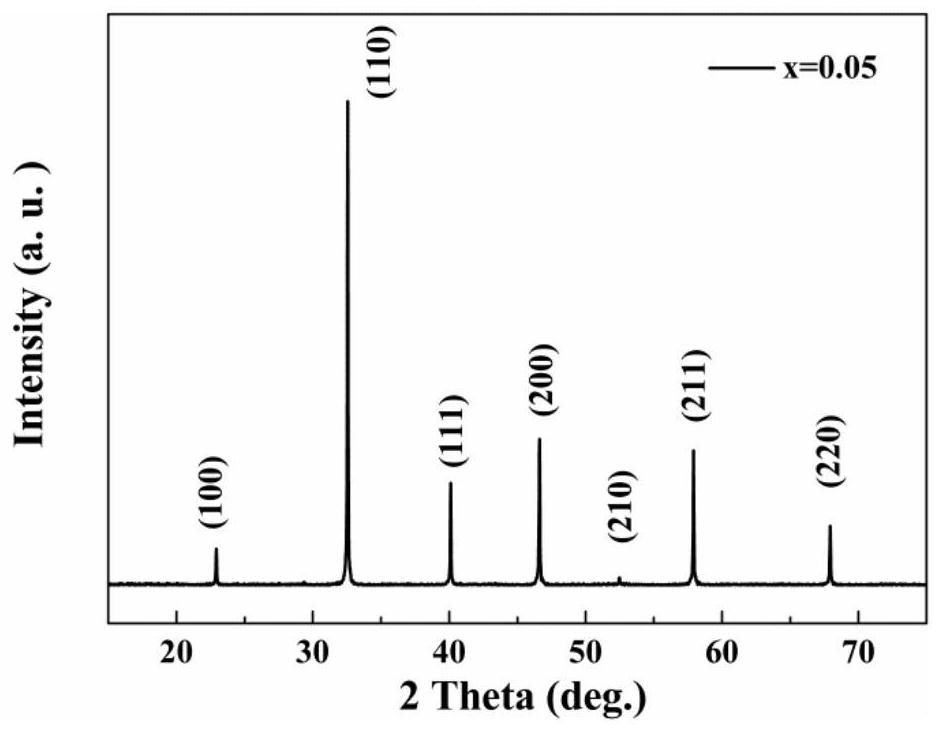

Embodiment 1

[0066] The chemical formula of the ceramic material in this example is: (1-x)(Na 0.5 Bi 0.5 ) 0.7 Sr 0.3 TiO 3 -xBi(Mg 2 / 3 Nb 1 / 3 )O 3 , where x represents the mole fraction and x=0.05.

[0067] The above-mentioned preparation method of the ceramic material with high energy storage performance and ultra-fast discharge rate comprises the following steps:

[0068] (1) According to the chemical formula (1-x) (Na 0.5 Bi 0.5 ) 0.7 Sr 0.3 TiO 3 -xBi(Mg 2 / 3 Nb 1 / 3 )O 3 Analytically pure SrCO 3 , Na2 CO 3 , TiO 2 , Bi 2 O 3 , MgO and Nb 2 O 5 Ingredients, where x represents the mole fraction, and x=0.05, with absolute ethanol as the medium, mixed uniformly by ball milling for 22 hours, then dried at 100 ° C, passed through a 120-mesh sieve, briqueted, and then pre-fired at 900 ° C for 3 120 mesh sieves to obtain calcined powder;

[0069] (2) using absolute ethanol as a medium for the pre-fired powder obtained in step (1), ball-milling for 22 hours, then drying a...

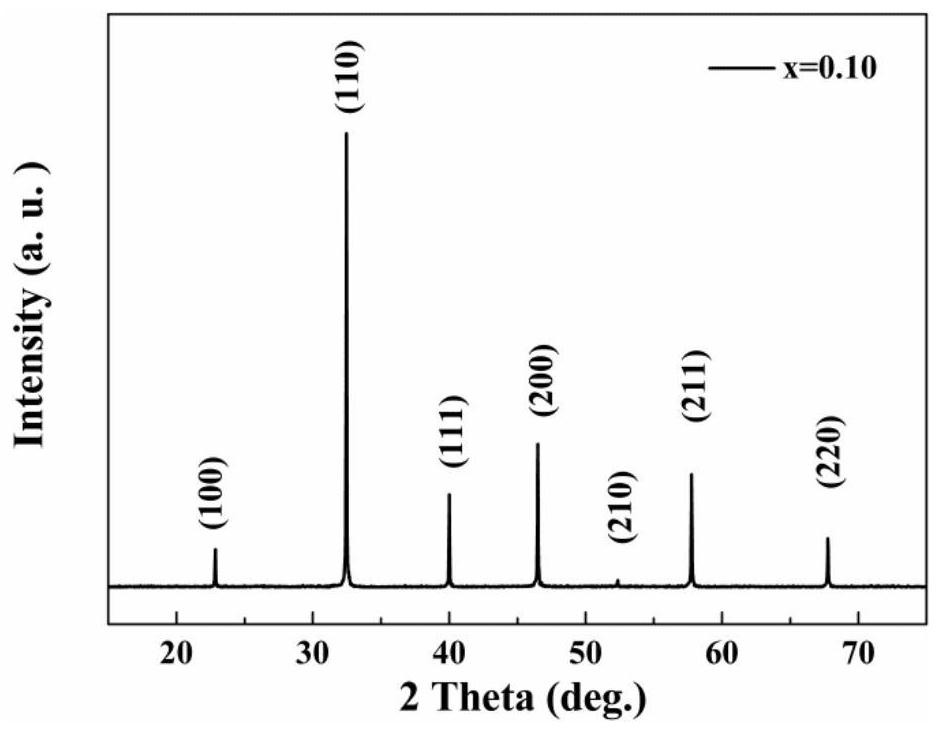

Embodiment 2

[0074] The chemical formula of the ceramic material in this example is: (1-x)(Na 0.5 Bi 0.5 ) 0.7 Sr 0.3 TiO 3 -xBi(Mg 2 / 3 Nb 1 / 3 )O 3 , where x represents the mole fraction, and x=0.10.

[0075] The above-mentioned preparation method of the ceramic material with high energy storage performance and ultra-fast discharge rate comprises the following steps:

[0076] (1) According to the chemical formula (1-x) (Na 0.5 Bi 0.5 ) 0.7 Sr 0.3 TiO 3 -xBi(Mg 2 / 3 Nb 1 / 3 )O 3 Analytically pure SrCO 3 , Na 2 CO 3 , TiO 2 , Bi 2 O 3 , MgO and Nb 2 O 5 Ingredients, where x represents the mole fraction, and x=0.10, with anhydrous ethanol as the medium, mixed uniformly by ball milling for 23 hours, then dried at 100 ° C, passed through a 120-mesh sieve, briqueted, and then pre-fired at 850 ° C for 4 120 mesh sieves to obtain calcined powder;

[0077] (2) using absolute ethanol as a medium for the pre-fired powder obtained in step (1), ball-milling for 23 hours, then dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com