Barium titanate-based relaxor ferroelectric ceramic powder, ceramic and preparation method and application thereof

A barium titanate-based, ceramic powder technology, applied in the direction of circuits, capacitors, electrical components, etc., can solve the problems of low dielectric breakdown field strength, low maximum polarization strength, hindering practical applications, etc., and achieve dielectric shock Enhanced through-field strength, excellent current density, and suppression of remanent polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

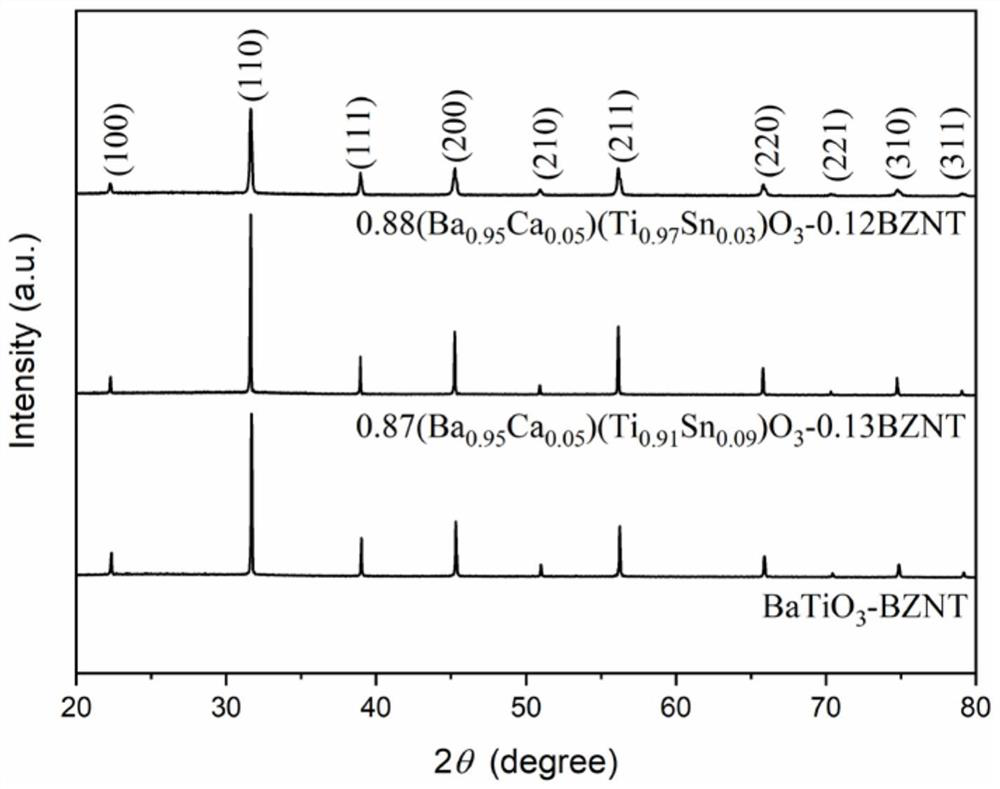

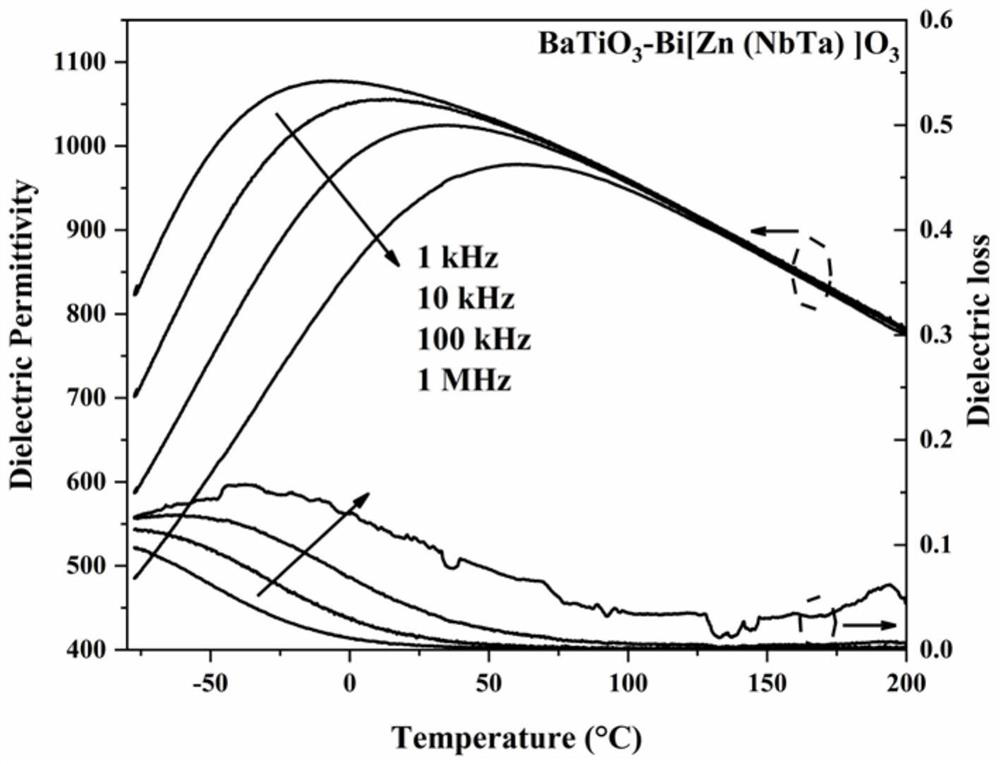

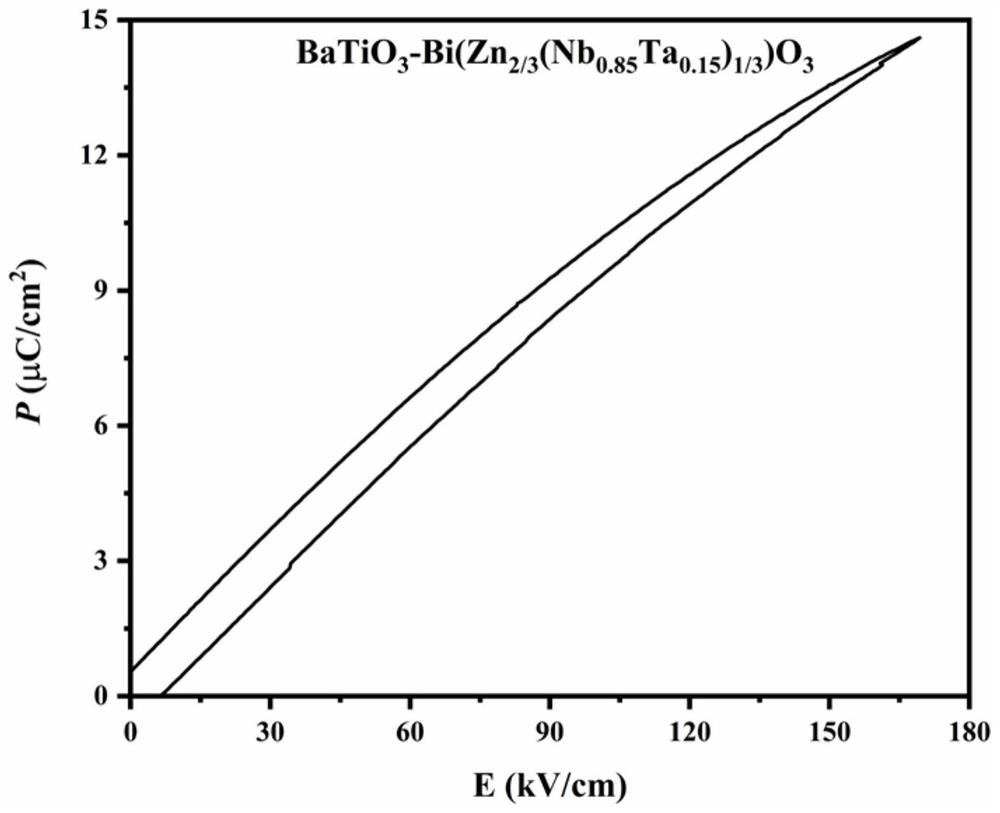

[0083] Preparation (1-Z) (Ba 1-x CA x (Ti) 1-y SN y ) O 3 -ZBi (Zn 2 / 3 (NB 0.85 TA 0.15 ) 1 / 3 ) O 3 , X = 0, y = 0, z = 0.13 Take the material, the raw material selection Baco 3 , TIO 2 , BI 2 O 3 , ZnO, NB 2 O 5 , TA 2 O 5 , 0.87batio according to chemistry 3 -0.13bi (Zn 2 / 3 (NB 0.85 TA 0.15 ) 1 / 3 ) O 3The chemometrics ratio of BA, Ti, Bi, Zn, Nb and TA elements weigh the raw materials, and the raw material weighing is placed in the ball mill, and zirconia balls and anhydrous ethanol are added to the ball mill, and the ball milling for 16 h. After drying in an oven (80 ° C, 4H), a mixed powder A is obtained, wherein the mass ratio of the anhydrous ethanol and the feedstock is 3: 1; the mass ratio of zirconia balls and raw materials used in the ball mill is 2: 1. The mixed powder A is placed in the alumina crucible, the pre-feeding temperature is 850 ° C, the temperature rise rate is 3 ° C / min, after 4 hours, naturally cooled to obtain a pre-feeding powder B. After the pre-feeti...

Embodiment 2

[0099] Preparation (1-Z) (Ba 1-x CA x (Ti) 1-y SN y ) O 3 -ZBi (Zn 2 / 3 (NB 0.85 TA 0.15 ) 1 / 3 ) O 3 , X = 0.05, y = 0.09, z = 0.13 Take the raw material to select Baco 3 Caco 3 , TIO 2 SNO 2 , BI 2 O 3 , ZnO, NB 2 O 5 , TA 2 O 5 Press Formula 0.87 (BA 0.95 CA 0.05 (Ti) 0.91 SN 0.09 ) O 3 -0.13bi (Zn 2 / 3 (NB 0.85 TA 0.15 ) 1 / 3 ) O 3 The medium element ratio is referred to as the selected raw material, the pre-feeding temperature is 850 ° C, and the insulation temperature of the ceramic embgeject after the discharge treatment is 1200 ° C, and the upper and lower sides of the sintered ceramic sheet are grinded to a thickness of 0.20 mm, and then The silver-plated electrode, the silver electrode has a diameter of 2.1 mm, and the remaining experimental conditions and examples are consistent.

[0100] It can be seen that the final sample obtained in this embodiment is 0.87 (BA) of the relaxed iron power storage ceramic material in the present invention. 0.95 CA 0.05 (Ti) 0.91 SN 0.09 ) ...

Embodiment 3

[0102] Preparation (1-Z) (Ba 1-x CA x (Ti) 1-y SN y ) O 3 -ZBi (Zn 2 / 3 (NB 0.85 TA 0.15 ) 1 / 3 ) O 3, X = 0.05, y = 0.03, z = 0.12 Take the material, the raw material selection Baco 3 Caco 3 , TIO 2 SNO 2 , BI 2 O 3 , ZnO, NB 2 O 5 , TA 2 O 5 , According to the formula 0.88 (Ba 0.95 CA 0.05 (Ti) 0.97 SN 0.03 ) O 3 -0.12bi (Zn 2 / 3 (NB 0.85 TA 0.15 ) 1 / 3 ) O 3 The medium element ratio is called the selected raw material, the pre-feet temperature is 1000 ° C, the insulation temperature of the ceramic embgeject after the disc bonding treatment is 1170 ° C, and the upper and lower sides of the sintered ceramic sheet are grinded to a thickness of 0.30 mm, and then The gold plating electrode, the diameter of the gold electrode is 2 mm, and 20 min at 250 ° C, the remaining experimental conditions and the first embodiment are consistent.

[0103] It is understood that the final sample obtained in this embodiment is 0.88 (Ba) relaxed iron power storage ceramic material in the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com