A kind of preparation method of medium temperature solid fuel cell electrolyte material

A solid fuel cell and electrolyte material technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of low conductivity, poor sintering performance and sintering density, and achieve improved ionic conductivity, increased crystal phase, and improved sintering. The effect of ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

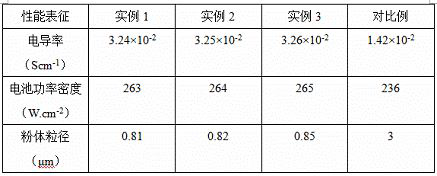

Examples

example 1

[0023] Take 1.8g of gadolinium oxide and 1.7g of samarium oxide, add it to 100g of nitric acid solution with a mass fraction of 20%, stir at 300r / min for 15min, then add 34.7g of cerium nitrate hexahydrate, continue stirring until the solid is completely dissolved, then add 9.6g of citric acid , 2.9g ethylenediaminetetraacetic acid, after stirring and mixing evenly, add dropwise a 5% sodium hydroxide solution until the pH is 8, and let it stand for 15 hours to obtain a reaction solution, which is transferred to a tank with a Teflon liner In a hydrothermal kettle, carry out a hydrothermal reaction at 120°C, the hydrothermal reaction time is 10h, cool to room temperature and filter to obtain a filter residue, wash the filter residue twice with absolute ethanol, then wash twice with deionized water, and then place In a drying oven, dry at 120°C to a constant weight to obtain a precursor. Put the precursor in a muffle furnace and ignite it to generate a self-propagating combustion ...

example 2

[0025] Take 2.3g of gadolinium oxide and 2.2g of samarium oxide, add 125g of nitric acid solution with a mass fraction of 20%, stir at 350r / min for 17min, then add 43.7g of cerium nitrate hexahydrate, continue stirring until the solid is completely dissolved, then add 12g of citric acid, 3.6g of ethylenediaminetetraacetic acid, after stirring and mixing evenly, add dropwise a 5% sodium hydroxide solution until the pH is 8.5, and let it stand for 17 hours to obtain a reaction solution, which is transferred to a water tank with a Teflon liner. In a hot kettle, carry out hydrothermal reaction at 150°C. The hydrothermal reaction time is 11 hours. After cooling to room temperature, filter the filter residue. Wash the filter residue with absolute ethanol for 2 times, then wash it with deionized water for 3 times, and then place it in a dry place. In the oven, dry at 135°C to constant weight to obtain the precursor. Put the precursor in a muffle furnace and ignite it to generate a sel...

example 3

[0027] Take 2.7g of gadolinium oxide and 2.6g of samarium oxide, add it to 150g of nitric acid solution with a mass fraction of 20%, stir at 400r / min for 20min, then add 52.1g of cerium nitrate hexahydrate, continue stirring until the solid is completely dissolved, then add 14.4g of citric acid , 4.4g of ethylenediaminetetraacetic acid, after stirring and mixing evenly, add dropwise a mass fraction of 5% sodium hydroxide solution to a pH of 9, leave it for 20 hours to obtain a reaction solution, and transfer the reaction solution to a tank with a Teflon liner In a hydrothermal kettle, carry out a hydrothermal reaction at 180°C. The hydrothermal reaction time is 12 hours. After cooling to room temperature, filter the filter residue, wash the filter residue 3 times with absolute ethanol, then wash 3 times with deionized water, and then place In a drying oven, dry at 150°C to a constant weight to obtain a precursor. Put the precursor in a muffle furnace and ignite it to undergo a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com