Polymer actuator

A polymer and actuator technology, applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, generators/motors, etc., can solve problems such as low insulation breakdown strength , to achieve the effects of small temperature dependence, excellent flexibility and elongation, and high dielectric breakdown strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] The method for producing the polyurethane elastomer molded article of the present invention can use: a method using a forming die; or when its thickness is small, sandwiching the polyurethane elastomer composition between release-treated films with spacers, and then allowing it to pass through A method of controlling the gap to a nip roll of desired thickness. As for the curing conditions of the molded article described above, it is desirable that the curing temperature is 70 to 150° C., preferably 80 to 130° C. and the curing time is 1 to 24 hours. If the curing temperature of the above molded article is lower than 70° C., the hardenability of the polyurethane elastomer molded article is insufficient. On the other hand, if it is higher than 150°C, a large amount of by-products will be generated. Also, if the curing time of the above molded article is less than 1 hour, the hardenability of the polyurethane elastomer molded article is insufficient. On the other hand, i...

Embodiment 1

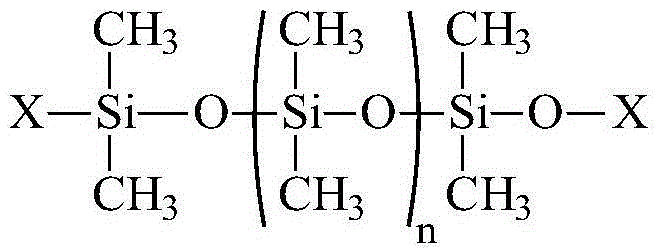

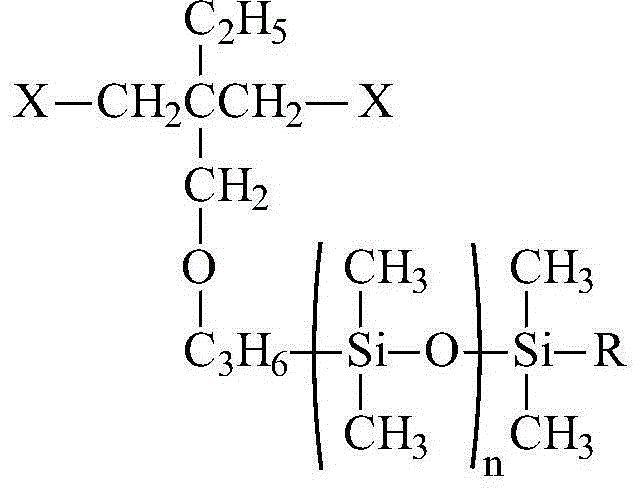

[0078] Into the reaction container, 41.4 parts by mass of side chain type reactive siloxane (manufactured by JNC Co., Ltd., "Silaplane FM-DA11", number average molecular weight 1,000, number of functional groups 2) and 41.4 parts by mass of polypropylene glycol ( "Excenol 7001", manufactured by Asahi Glass Co., Ltd., having a number average molecular weight of 6000 and a number of functional groups of 3), was dehydrated under reduced pressure for 1 hour while stirring. Then, the inside of the reaction vessel was replaced with nitrogen. Then, 17.8 parts by mass of toluene diisocyanate (manufactured by Mitsui Chemical Industry Co., Ltd., "T-100", 2,4-body=100) was added to the reaction vessel, and then reacted for 3 hours to synthesize isocyanate-terminated prepolymers.

[0079] Next, 100 parts by mass of the prepolymer was dissolved in 65.0 parts by mass of toluene. Next, 51.4 parts by mass of polypropylene glycol (manufactured by Asahi Glass Co., Ltd., "Excenol 1020", with a...

Embodiment 2

[0082] Except that 18.2 parts by mass of side chain type reactive siloxane (manufactured by JNC Co., Ltd., Silaplane FM-DA11, number average molecular weight 1,000, number of functional groups 2) was used for the polyol mixed solution when preparing the isocyanate-terminated prepolymer , 22.9 parts by mass of polypropylene glycol (manufactured by Asahi Glass Co., Ltd., Excenol 1020, number average molecular weight is 1000, and the number of functional groups is 2) and 41.4 parts by mass of polypropylene glycol (manufactured by Asahi Glass Co., Ltd., Excenol 7001, number average molecular weight is 6000, functional group Except that the number is 3), a polyurethane elastomer membrane actuator was prepared in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com