Method for preparing strontium barium niobate ceramics with high pyroelectric effects

A technology of barium strontium niobate and electrocaloric effect, which is applied in the field of high electrocaloric effect ceramic materials and its preparation, can solve the problems of affecting the ferroelectric properties of ceramics, affecting the ferroelectric effect, etc. Uniform, small grain size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

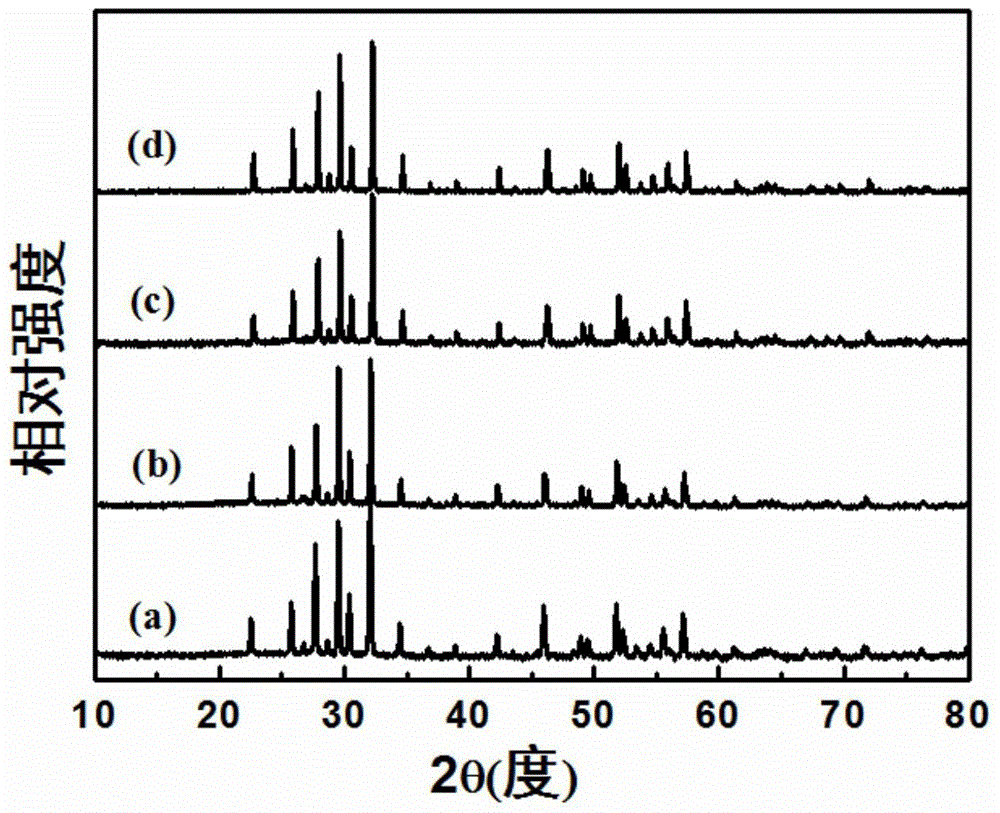

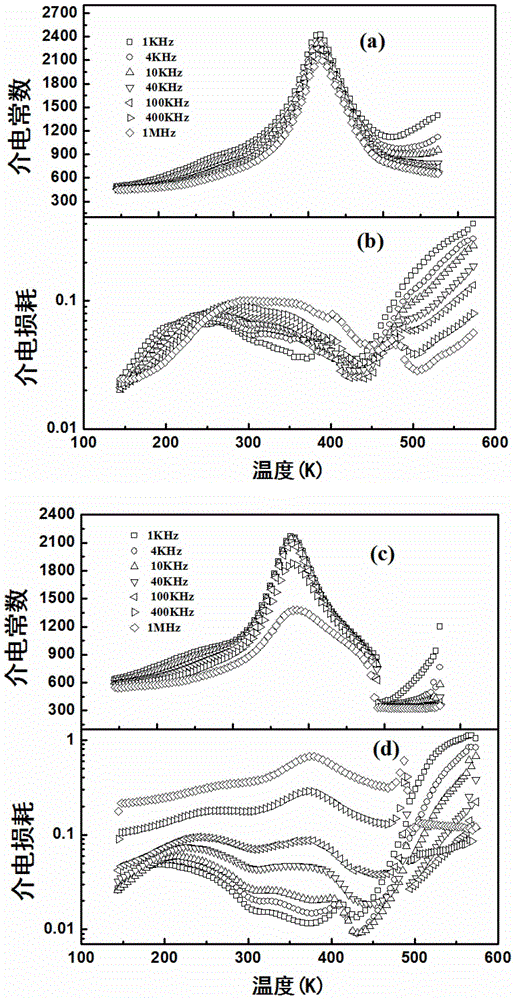

[0026] (1) BaCO 3 , SrCO 3 and Nb 2 o 5 The raw material powder is respectively according to Sr 0.4 Ba 0.6 Nb 2 o 6 Chemical formula weighing ingredients;

[0027] (2) Put the chemical raw material prepared in step (1) into a ball milling jar, and add ZrO in the plastic ball milling jar 2 Zirconium balls are added with absolute ethanol, and placed on a ball mill for ball milling for 24 hours (with a particle size of 100nm to 400nm). The milled powder is dried in an oven and sieved through a 120-mesh sieve. The prepared powder was calcined at 1200°C for 3 hours, cooled to 1100°C at 2°C / min, then cooled to room temperature with the furnace, and passed through a 120-mesh sieve to obtain Sr 0.4 Ba 0.6 Nb 2 o 6 Powder;

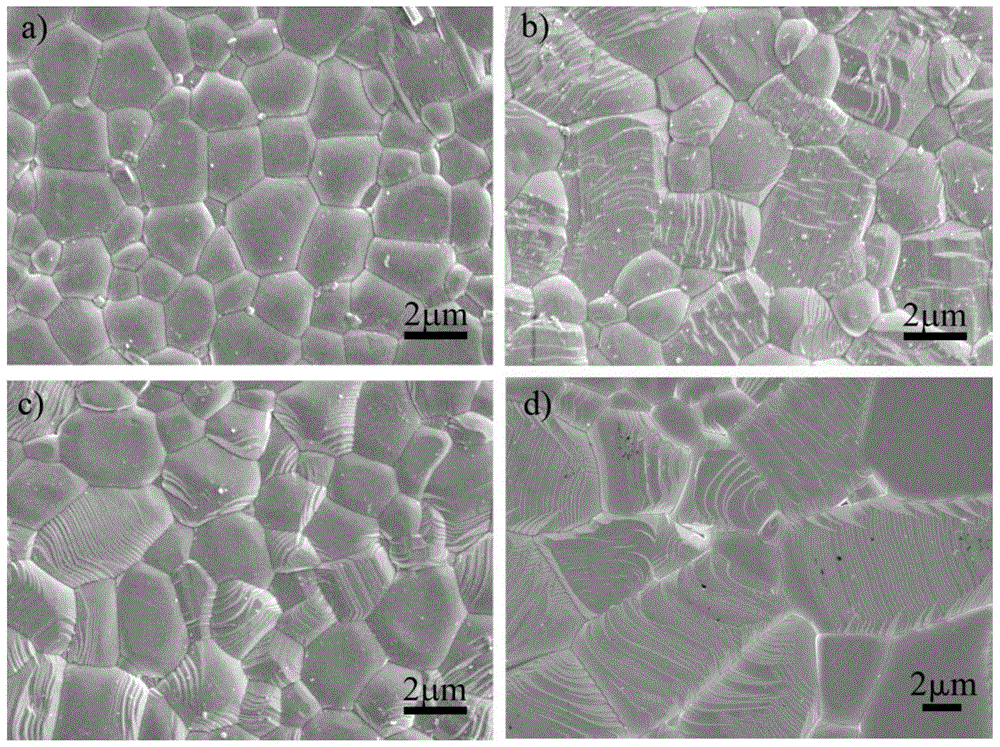

[0028] (3) Put the powder prepared in step (2) into a graphite mold with a diameter of 10mm, put it into a spark plasma sintering system and sinter at 1000°C and 30MPa mechanical pressure, keep it warm for 5 minutes, and the heating rate from room tempe...

Embodiment 2

[0032] (1) BaCO 3 , SrCO 3 and Nb 2 o 5 The raw material powder is respectively according to Sr 0.5 Ba 0.5 Nb 2 o 6 Chemical formula weighing ingredients;

[0033] (2) Put the chemical raw material prepared in step (1) into a ball milling jar, and add ZrO in the plastic ball milling jar 2 Zirconium balls are added with absolute ethanol, and placed on a ball mill for ball milling for 24 hours (with a particle size of 100nm to 400nm). The milled powder is dried in an oven and sieved through a 120-mesh sieve. The prepared powder was calcined at 1200°C for 3 hours, cooled to 1100°C at 2°C / min, then cooled to room temperature with the furnace, and passed through a 120-mesh sieve to obtain Sr 0.5 Ba 0.5 Nb 2 o 6 Powder;

[0034] (3) Put the powder prepared in step (2) into a graphite mold with a diameter of 10mm, put it into a spark plasma sintering system and sinter it under 1025°C and 30MPa mechanical pressure, keep it warm for 5 minutes, and the heating rate from room...

Embodiment 3

[0037] (1) BaCO 3 , SrCO 3 and Nb 2 o 5 The raw material powder is respectively according to Sr 0.6 Ba 0.4 Nb 2 o 6 Chemical formula weighing ingredients;

[0038] (2) Put the chemical raw material prepared in step (1) into a ball milling jar, and add ZrO in the plastic ball milling jar 2 Zirconium balls are added with absolute ethanol, and placed on a ball mill for ball milling for 24 hours (with a particle size of 100nm to 400nm). The milled powder is dried in an oven and sieved through a 120-mesh sieve. The prepared powder was calcined at 1300°C for 3 hours, cooled to 1100°C at 2°C / min, cooled to room temperature with the furnace, and passed through a 120-mesh sieve to obtain Sr 0.6 Ba 0.4 Nb 2 o 6 Powder;

[0039] (3) Put the powder obtained in step (2) into a graphite mold with a diameter of 10mm, put it into a spark plasma sintering system and sinter it at 1050°C and 30MPa mechanical pressure, keep it warm for 5 minutes, and the heating rate from room tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com