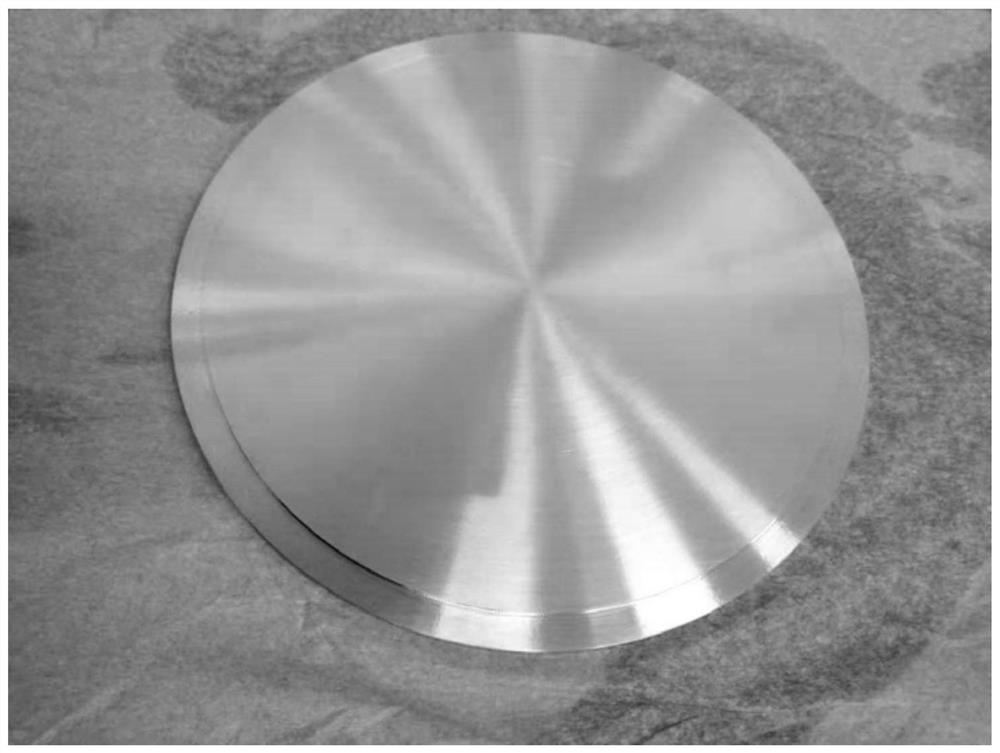

Preparation method of nickel-iron-copper-molybdenum alloy target material

A molybdenum alloy and nickel-iron-copper technology is applied in the field of nickel-iron-copper-molybdenum alloy target preparation, which can solve the problems of affecting the sputtering film quality, high gas impurity content, prolonging the production cycle, etc., and achieves low sputtering power and high sputtering power. Magnetic permeability, the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

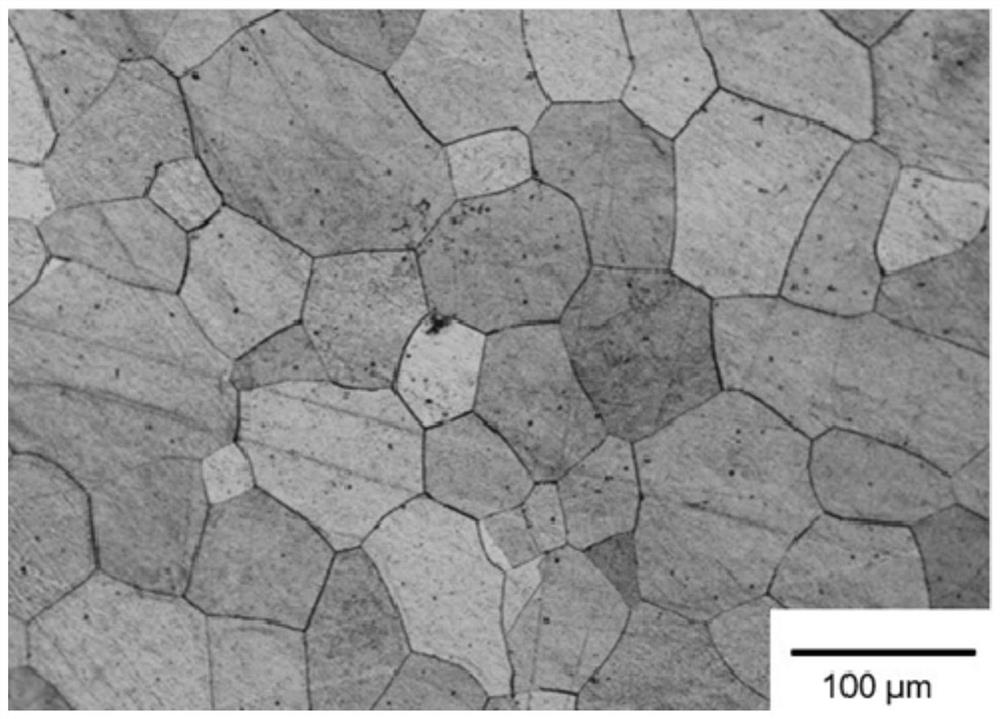

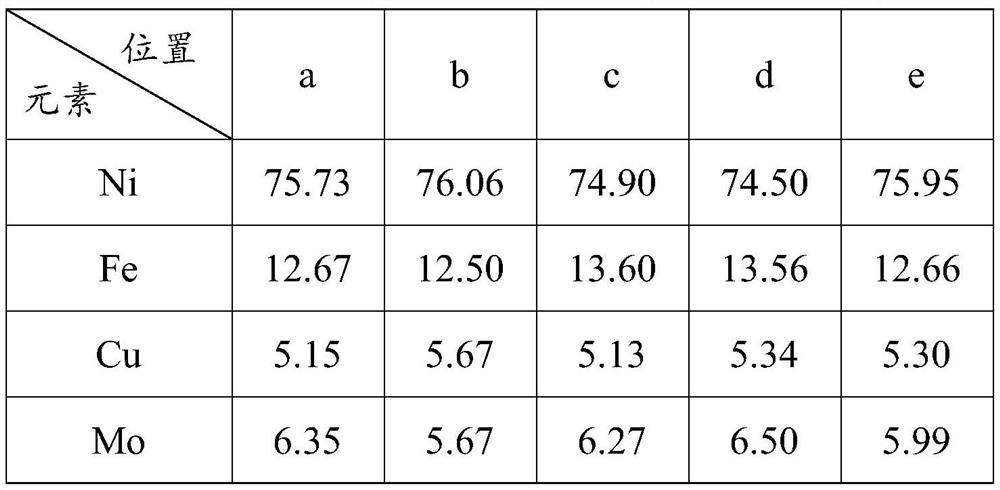

Embodiment 1

[0033] An embodiment of a method for preparing a nickel-iron-copper-molybdenum target of the present invention is as follows:

[0034] (1) Weigh 8.169kg of Ni, 1.414kg of Fe, 0.574kg of Cu and 0.693kg of Mo raw materials according to the required ratio of the target material, and put the Ni and Mo raw materials into a water-cooled copper crucible;

[0035] (2) Vacuumize the water-cooled copper crucible to 2.0×10 -2 Pa, fill the furnace with nitrogen to wash the furnace, after vacuuming again, fill with new nitrogen, keep the pressure in the melting furnace at 0.06MPa, let the Ni and Mo materials be heated to 1500°C in a vacuum environment, and the materials will be completely melted after smelting for 14 minutes , cooled to room temperature to obtain alloy ingot A;

[0036] (3) Put the weighed Fe and Cu raw materials into a water-cooled copper crucible equipped with alloy ingot A, and the water-cooled copper crucible is evacuated to 2.0×10 -2 Pa, fill the furnace with nitrog...

Embodiment 2

[0044] An embodiment of a method for preparing a nickel-iron-copper-molybdenum target of the present invention is as follows:

[0045] (1) Weigh 8.130kg of Ni, 1.347kg of Fe, 0.517kg of Cu and 0.636kg of Mo raw materials according to the required ratio of the target material, and put the Ni and Mo raw materials into a water-cooled copper crucible;

[0046] (2) Vacuumize the water-cooled copper crucible to 2.0×10 -2 Pa, fill the furnace with nitrogen to wash the furnace, and after vacuuming again, fill in new nitrogen to keep the pressure in the melting furnace at 0.06MPa, let the Ni and Mo materials be heated to 1550°C in a vacuum environment, and the materials will be completely melted after smelting for 7 minutes , cooled to room temperature to obtain alloy ingot A;

[0047] (3) Put the weighed Fe and Cu raw materials into a water-cooled copper crucible equipped with alloy ingot A, and the water-cooled copper crucible is evacuated to 2.0×10 -2 Pa, fill the furnace with nit...

Embodiment 3

[0054] An embodiment of a method for preparing a nickel-iron-copper-molybdenum target of the present invention is as follows:

[0055] (1) Weigh 8.324kg of Ni, 1.474kg of Fe, 0.633kg of Cu and 0.753kg of Mo raw materials according to the required ratio of the target material, and put the Ni and Mo raw materials into a water-cooled copper crucible;

[0056] (2) Vacuumize the water-cooled copper crucible to 2.0×10 -2 Pa, fill the furnace with nitrogen to wash the furnace, and after vacuuming again, fill in new nitrogen to keep the pressure in the melting furnace at 0.12MPa, let the Ni and Mo materials be heated to 1500°C in a vacuum environment, and the materials will be completely melted after smelting for 14 minutes , cooled to room temperature to obtain alloy ingot A;

[0057] (3) Put the weighed Fe and Cu raw materials into a water-cooled copper crucible equipped with alloy ingot A, and the water-cooled copper crucible is evacuated to 2.0×10 -2 Pa, fill the furnace with ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com