Apparatus and method for preparing nd-rich phase nd2fe14b/α-fe permanent magnets by stepped hot extrusion

A nd2fe14b, hot extrusion technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., to achieve high magnetic performance, reduce the appearance of cracks, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

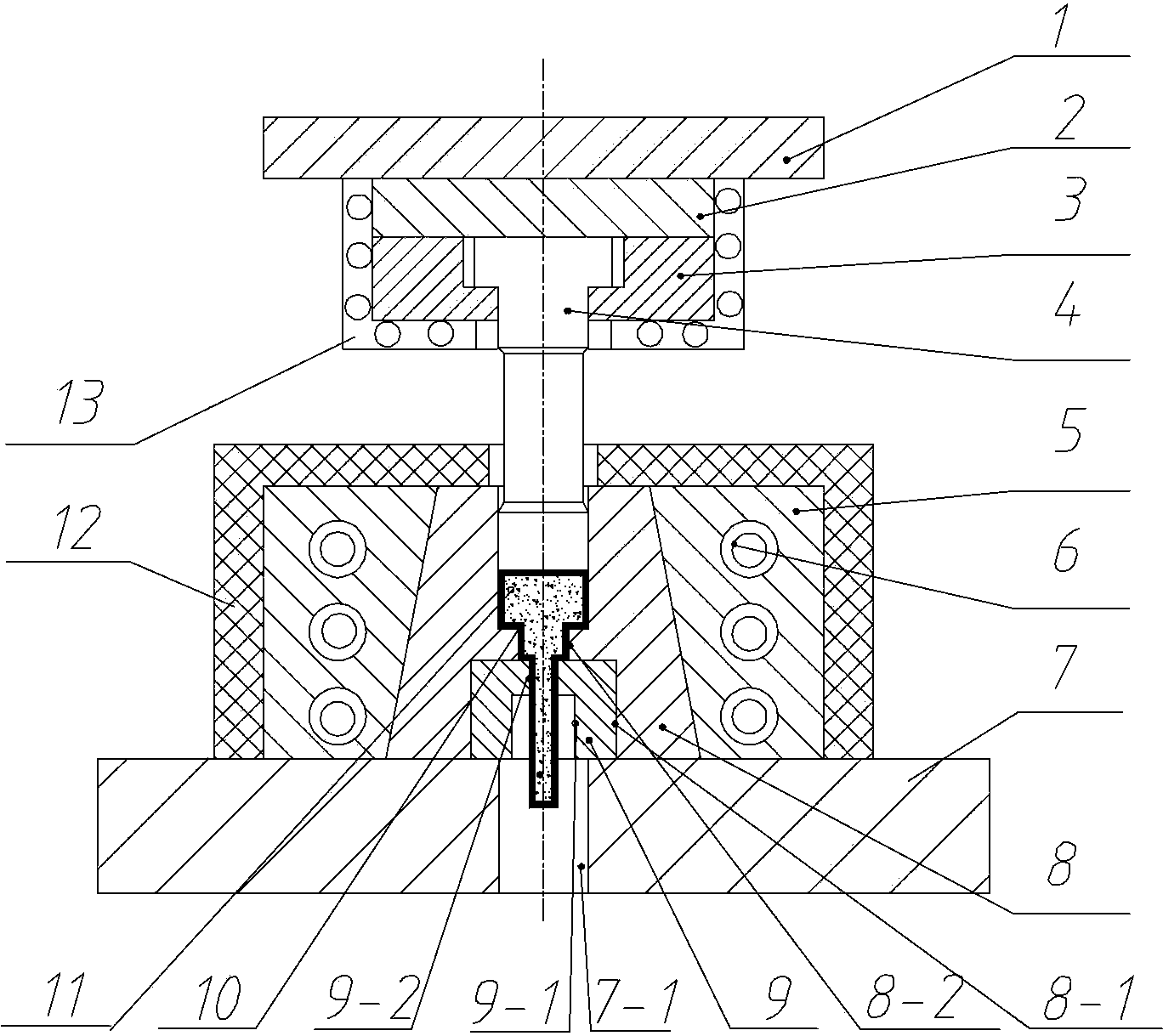

[0009] Specific implementation mode one: combine figure 1 Describe this embodiment, the device of this embodiment includes an upper template 1, a backing plate 2, a punch fixing sleeve 3, an extrusion punch 4, an extrusion die sleeve 5, a resistance wire 6, a lower template 7, a first-stage extrusion Die 8, secondary extrusion die 9 and heating sleeve 13, the lower end surface of the upper template 1 is affixed to the upper end surface of the backing plate 2, and one end of the extrusion punch 4 is installed in the punch fixing sleeve 3 and connected to the backing plate 2. The lower end surface of the plate 2 is connected, the end of the backing plate 2, the punch fixing sleeve 3 and the extrusion punch 4 are all installed in the heating sleeve 13, the upper end surface of the heating sleeve 13 is fixedly connected with the upper template 1, and the extrusion die Cover 5 is provided with a first-stage extrusion die 8 and both are connected with the lower template 7, the first...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 Describe this embodiment, the angle between the generatrix of the primary extrusion die 8 and the diameter of the bottom circle in this embodiment is 5°-10°, the extrusion punch 4, the primary extrusion die 8 and the secondary extrusion Die 9 is processed by H13 forging billet, quenched and tempered to HRC48-52, extrusion die sleeve 5 is processed by 5CrNiMo forged billet, quenched and tempered to HRC45-48, so that the extrusion die and extrusion die can be ensured. Good comprehensive performance ensures the smooth progress of the extrusion process. Other implementation manners are the same as the specific implementation manner 1.

specific Embodiment approach 3

[0011] Specific embodiment three: the device of the present embodiment also includes a thermal insulation layer 12, the outer casing thermal insulation layer 12 of extrusion die cover 5, and the lower end surface of the thermal insulation layer 12 is affixed to the upper end surface of the lower formwork 7, so that electric energy can be saved , to ensure fast mold temperature rise and improve mold life. Other implementation manners are the same as the specific implementation manner 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com