Method for preparing gamma-Fe2O3 magnetic nano-particles

A nanoparticle, g-fe2o3 technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high cost, difficulty in large-scale implementation, difficult to control, etc., and achieve production speed Fast, uniform size, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

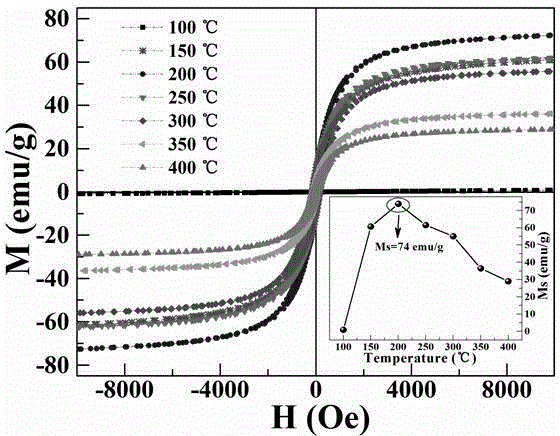

[0017] Carry out according to the above steps, only change the sintering at 100°C, 150°C, 250°C, 300°C, 350°C, 400°C, after sintering, take the product obtained in the crucible for corresponding test.

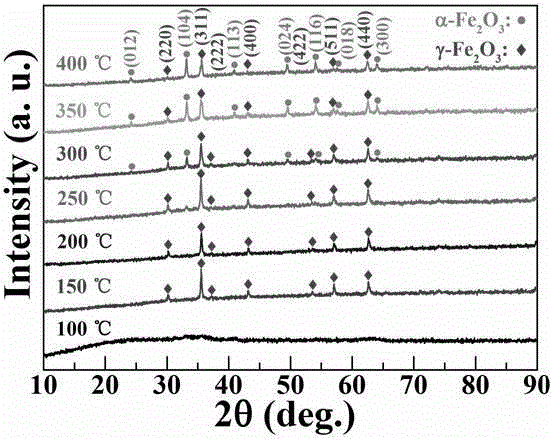

[0018] The X-ray diffraction spectrum of the obtained sample is as follows figure 2 As shown, it shows that g-Fe will be generated at sintering temperatures of 150°C, 200°C, and 250°C 2 o 3 Nanoparticle phase, if the temperature is too low (at 100°C), γ-Fe 2 o 3 No phase formation; if the temperature is too high (300°C, 350°C, 400°C), other phases of Fe will be produced 2 o 3 , resulting in a product that is not a single pure γ-Fe 2 o 3 Mutually.

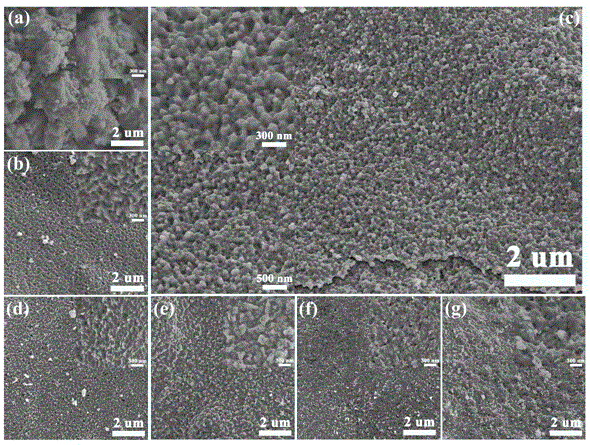

[0019] Visible by observing the obtained sample scanning electron microscope, see image 3 , the SEM photos at different temperatures can be seen, γ-Fe 2 o 3 When the sintering temperature of nanoparticles is 150°C [figure (b)], 200°C [figure (c)], 250°C [figure (d)], the size of the obtained particles is relatively unifor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com