Polypropylene film for capacitor

A polypropylene film and capacitor technology, applied in the direction of fixed capacitor dielectric, fixed capacitor parts, thin material processing, etc., can solve the problems of no example, no inspiration, unsatisfied, etc., to improve resistance, long life and long-term Durable, high dielectric breakdown strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

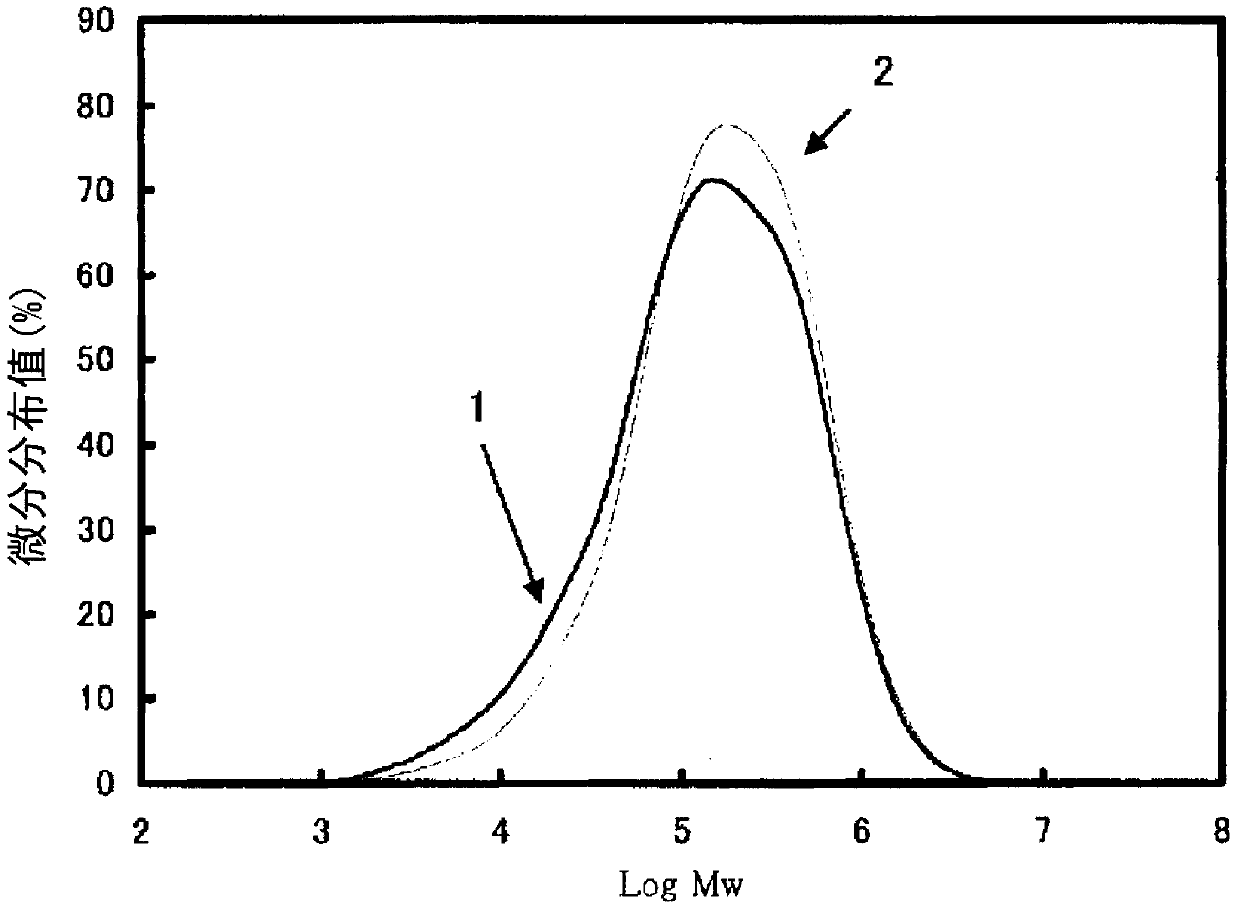

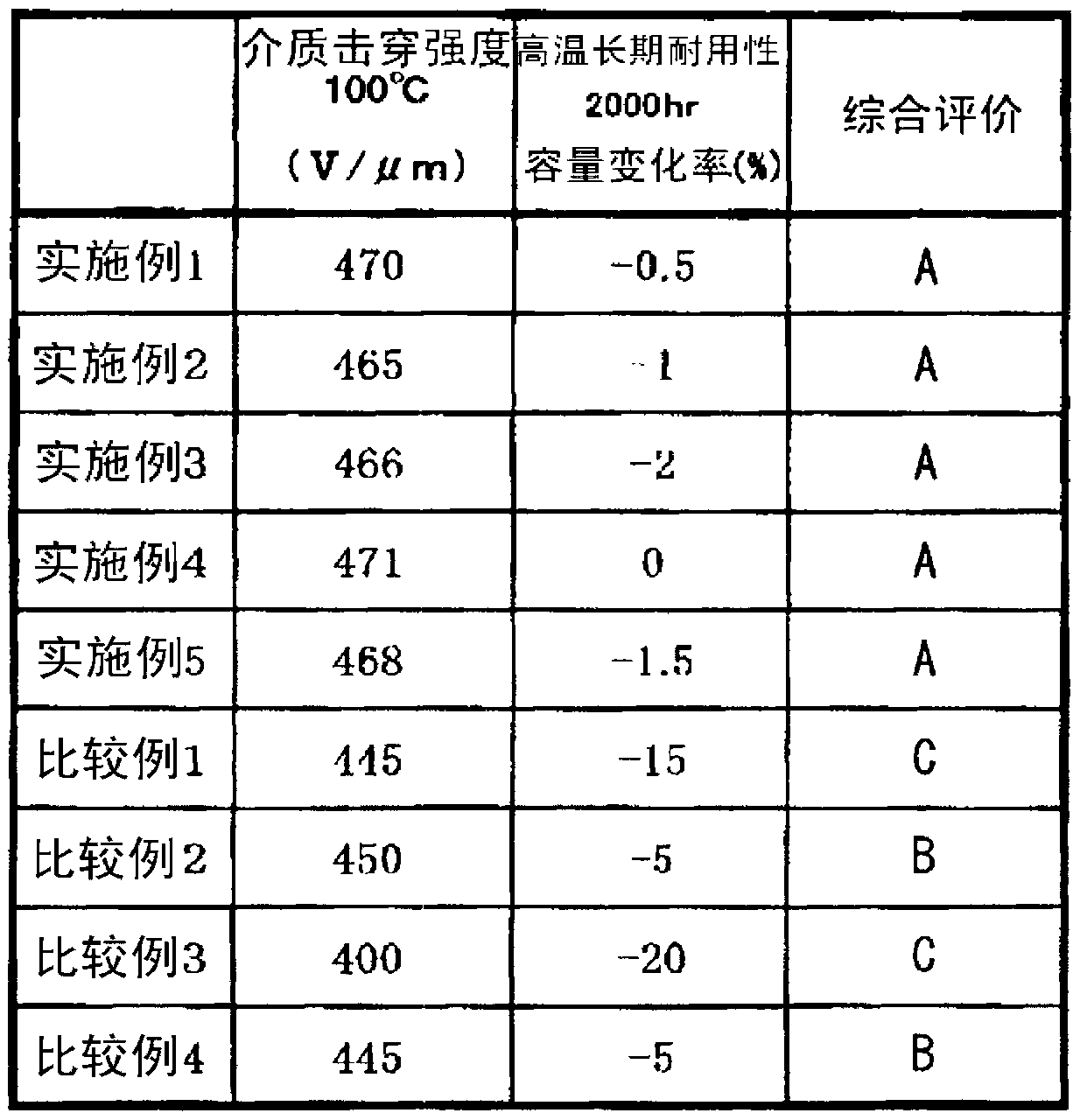

[0159] Add 5000ppm IRGANOX (registered trademark) 1010, 20ppm 2,5-dimethyl-2,5-di(t-butylperoxy)hexyl as secondary antioxidant to resin E manufactured by Prime Polymer Co., Ltd. Alkanes were melt-kneaded in a granulator, and the raw resin A whose molecular weight distribution was adjusted by peroxidative decomposition treatment was supplied to the extruder, melted at a resin temperature of 250°C, and extruded through a T-die. , was coiled to a metal drum whose surface temperature was maintained at 95° C. and solidified to produce a cast green sheet with a thickness of about 140 μm. Next, the unstretched cast green sheet was stretched to 5 times in the moving direction at a temperature of 140° C., immediately cooled to room temperature, and then stretched in the width direction at a temperature of 165° C. 10 times, a very thin biaxially stretched polypropylene film with a thickness of 2.8 μm was obtained. Table 1 summarizes the molecular characteristics of the obtained thin fi...

Embodiment 2

[0161] Instead of the raw resin A of Example 1, a raw resin B in which IRGANOX (registered trademark) 1010 as a secondary antioxidant was added to the molecular weight distribution adjustment resin B subjected to peroxidative decomposition treatment in the same manner as in Example 1 was supplied to The extruder was carried out in the same manner as in Example 1 except for this, and a very thin biaxially stretched polypropylene film having a thickness of 2.8 μm was obtained. Table 1 summarizes the molecular characteristics of the obtained thin film and the physical property values of the thin film. In addition, the evaluation results as capacitor films are summarized in Table 2. It should be noted that the difference in molecular weight differential distribution, molecular weight (Mw), molecular weight distribution (Mw / Mn), percentage of meso pentads, and residual secondary antioxidant in Table 1 are analytical values of the film.

Embodiment 3

[0163] Instead of the raw resin A of Example 1, a raw resin C in which 5500 ppm of IRGANOX (registered trademark) 1010 was added as a secondary antioxidant to the molecular weight distribution adjustment resin C subjected to peroxidative decomposition treatment was supplied to the extruder, except Except for this, a very thin biaxially stretched polypropylene film having a thickness of 2.8 μm was obtained in the same manner as in Example 1. Table 1 summarizes the molecular characteristics of the obtained thin film and the physical property values of the thin film. In addition, the evaluation results as capacitor films are summarized in Table 2. It should be noted that the difference in molecular weight differential distribution, molecular weight (Mw), molecular weight distribution (Mw / Mn), percentage of meso pentads, and residual secondary antioxidant in Table 1 are analytical values of the film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com