Manufacturing method for full-height multi-rotor unmanned aerial vehicle of foam structure

A multi-rotor unmanned aerial vehicle and foam structure technology, which is applied to unmanned aerial vehicles, fuselage, motor vehicles, etc., can solve the problems of high power consumption and increased battery weight, and achieve the effect of reducing the weight of the structure and improving the strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the following, specific examples of the production of the body structure in the present invention will be described in detail with reference to the accompanying drawings.

[0021] The manufacture of a full-height foam structure multi-rotor unmanned aerial vehicle body in the present invention comprises the following steps:

[0022] 1) Mold processing

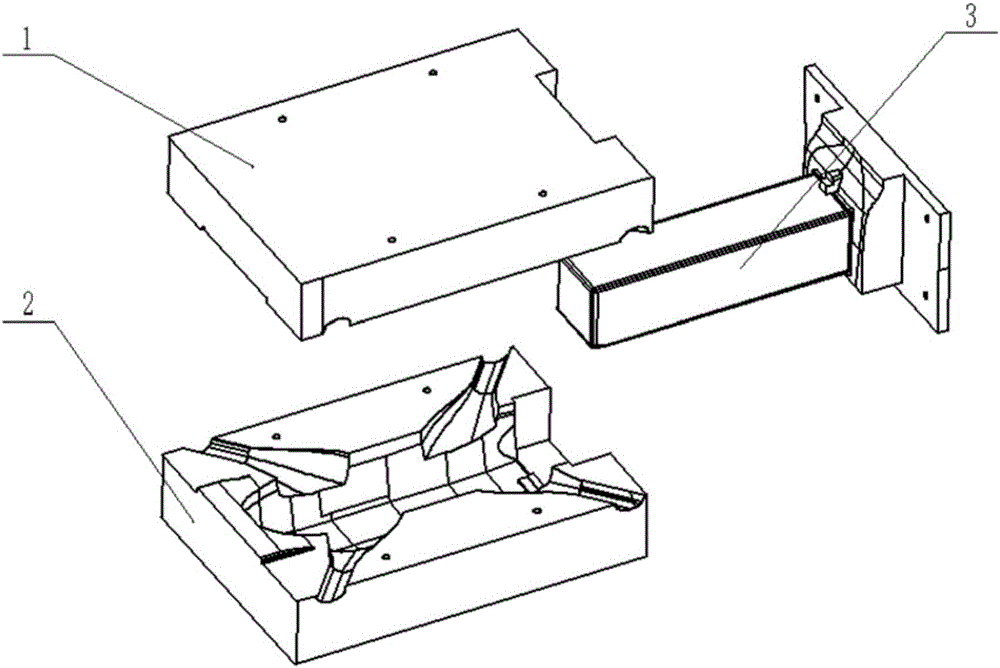

[0023] The upper mold 1, the lower mold 2, and the rear mold 3 are processed using metal materials. The produced mold should have high surface hardness and surface quality, and can adapt to temperature changes.

[0024] 2) Processing of foam core and plastic frame

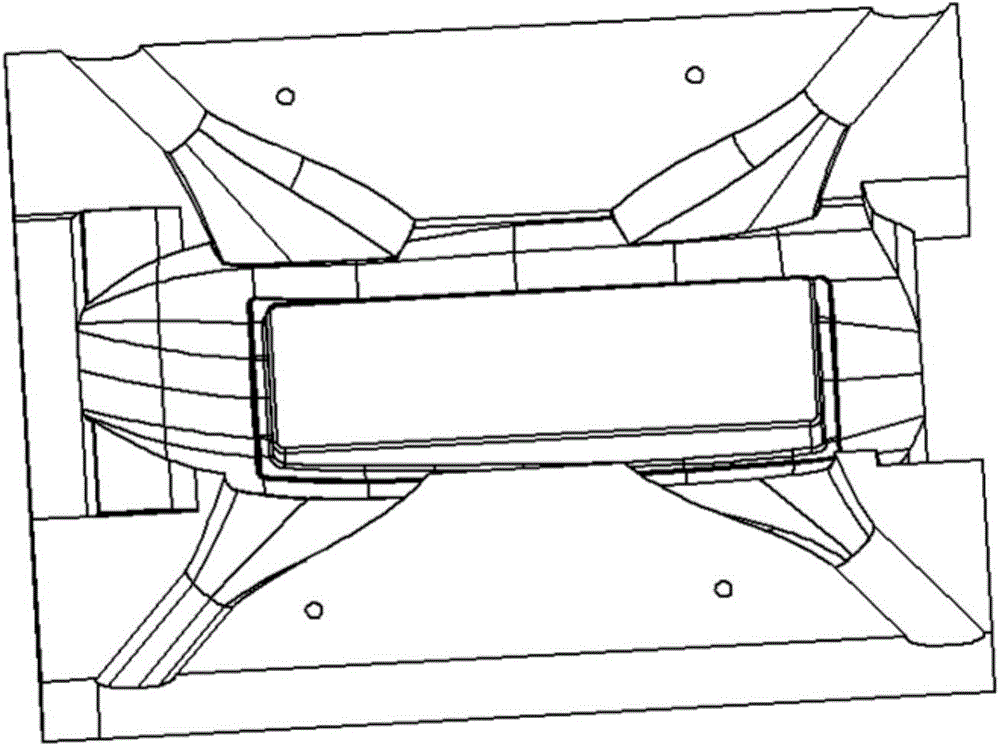

[0025] According to the exterior structure and cavity structure of the multi-rotor UAV, the foam core 4 is processed with PMI (polymethacryimide foam) with a density of about 40kg / m3, and the frame body 5 and the frame body 6 are processed with nylon material.

[0026] 3) Preparation of body skin

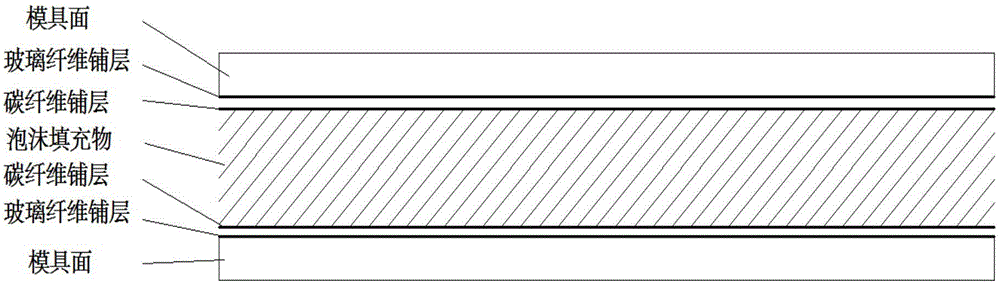

[0027] like image 3 As shown in the figure, the compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com