Novel filtering and concentrating device and main reaction kettle device

A concentration device, a new type of technology, applied in the direction of filtration separation, fixed filter element filter, chemical/physical/physical chemical fixed reactor, etc., to achieve the effects of easy disassembly, high equipment reliability, and slow flux attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

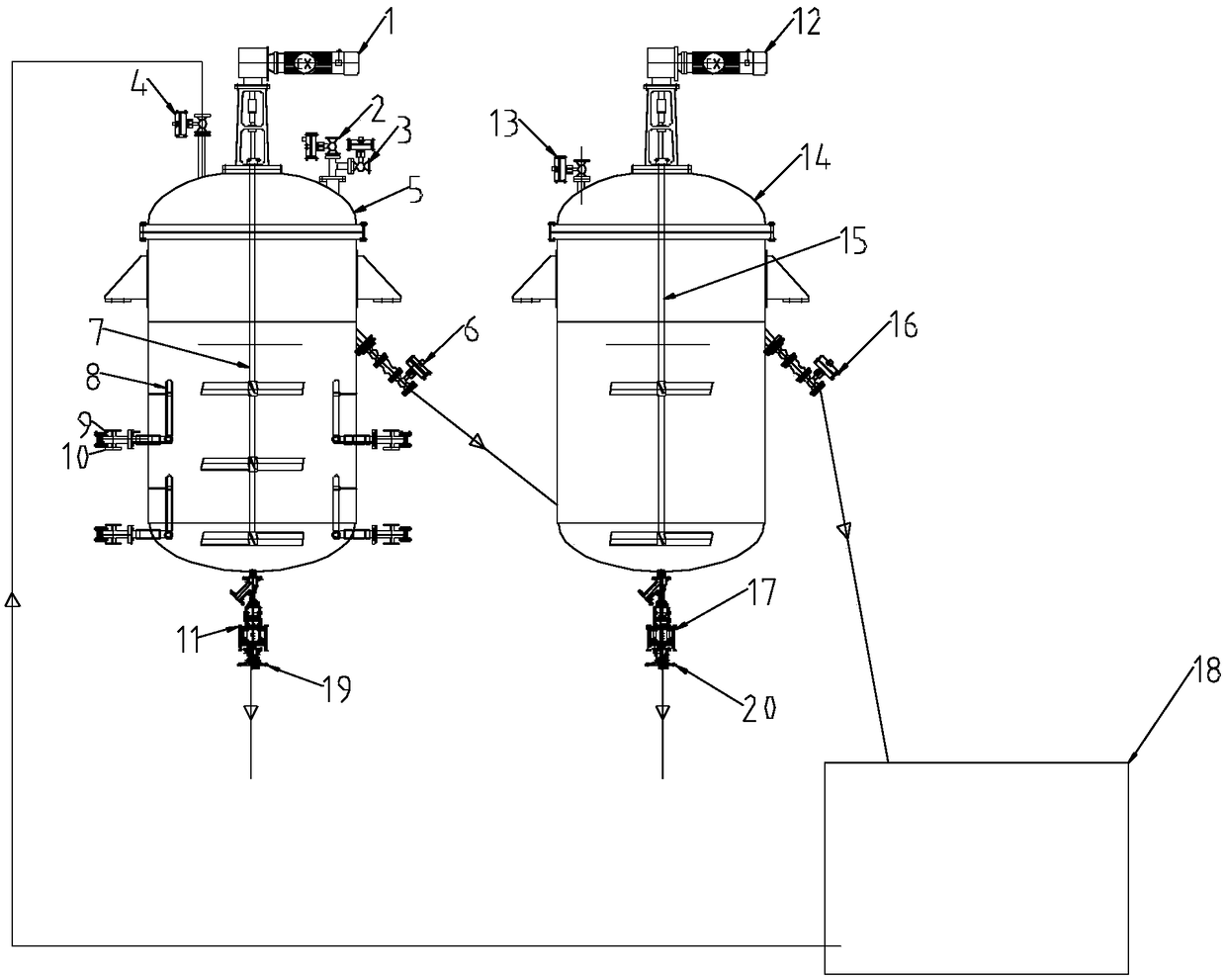

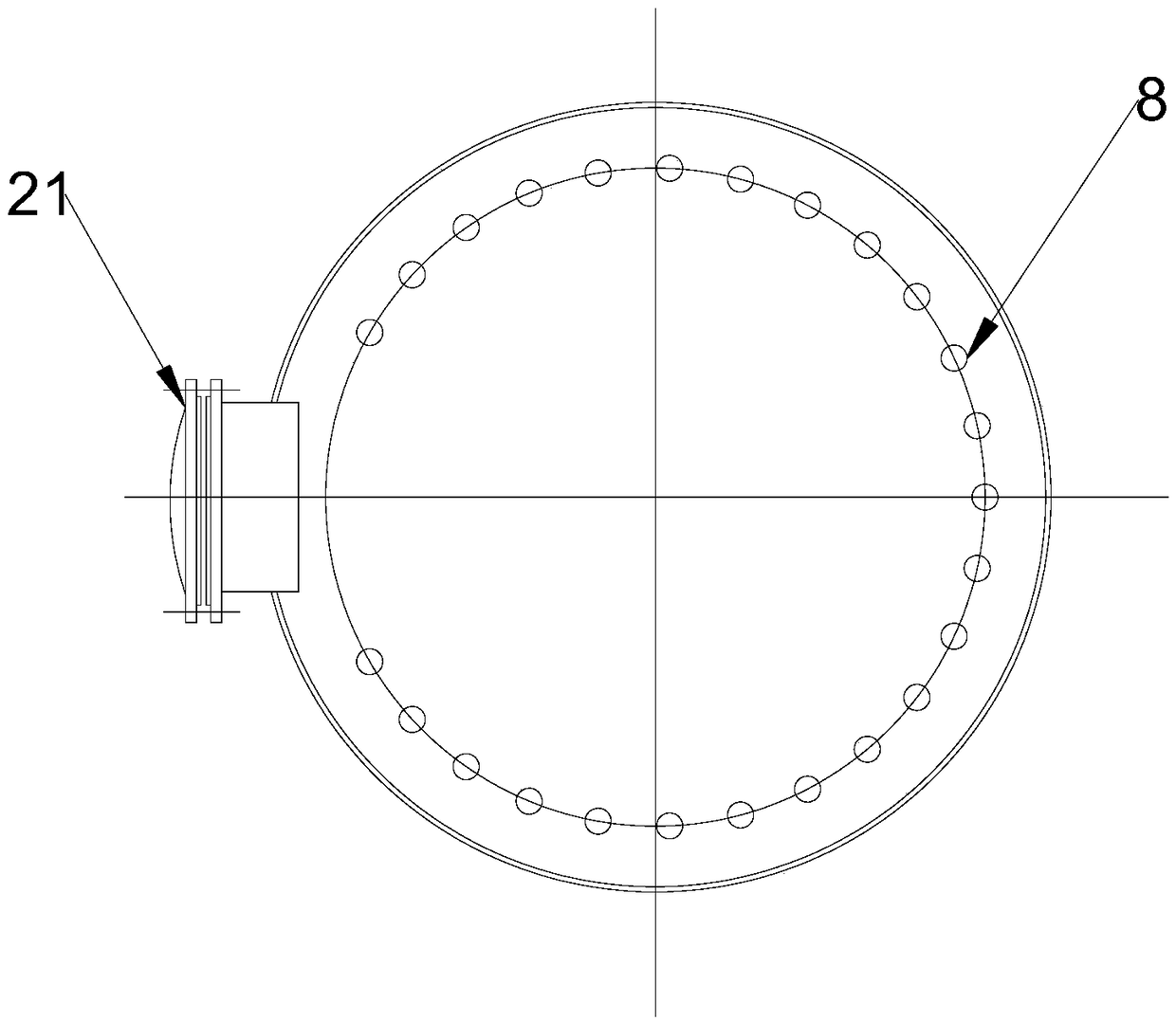

[0028] like figure 1 , figure 2 As shown, a new type of filtration concentration device and main reactor device in this example, including geared motor A1, regeneration liquid inlet 2, spray water inlet 3, nitrogen inlet 4, cylinder A5, process concentrated liquid outlet 6, stirring paddle A7, filter element 8, blowback port 9, clear liquid outlet 10, liquid discharge valve A11, gear motor B12, raw liquid feed port 13, cylinder B14, stirring paddle B15, overflow port 16, liquid discharge valve B17, intermediate tank 18 , final concentrated product exit A19, final concentrated product exit A20, manhole 21.

[0029] The reduction motor A1 is on the top of the cylinder A5, and the output shaft of the reduction motor A1 is connected to the top of the stirring paddle A7 to drive the stirring paddle A to rotate axially; the top of the cylinder A5 is provided with a regeneration liquid inlet connected to the inside of the cylinder A5 2. Spraying water inlet 3 and nitrogen inlet 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com