Energy saving nozzle of minimum quantity lubrication system

A technology of minimal quantity lubrication and nozzles, which is applied in the direction of injection devices, injection devices, liquid injection devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0123] Example as figure 1 As shown in Figure 6, Embodiment 2 is improved on the basis of Embodiment 1, as Figure 7 to Figure 1 1.

[0124] Embodiment 1 will be further described below in conjunction with the accompanying drawings.

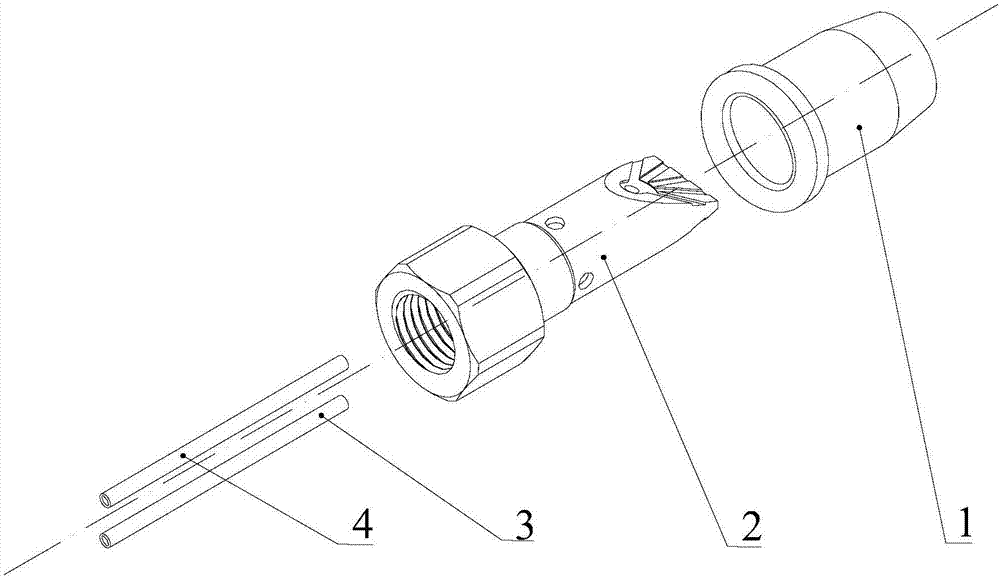

[0125] figure 1 It is a three-dimensional assembly diagram of an energy-saving nozzle for a minimal quantity lubrication system.

[0126] Such as figure 1 As shown, an energy-saving nozzle of a minimal quantity lubrication system includes: a nesting ring 1 , a nozzle body 2 , a lubricating oil input conduit 3 and a water input conduit 4 .

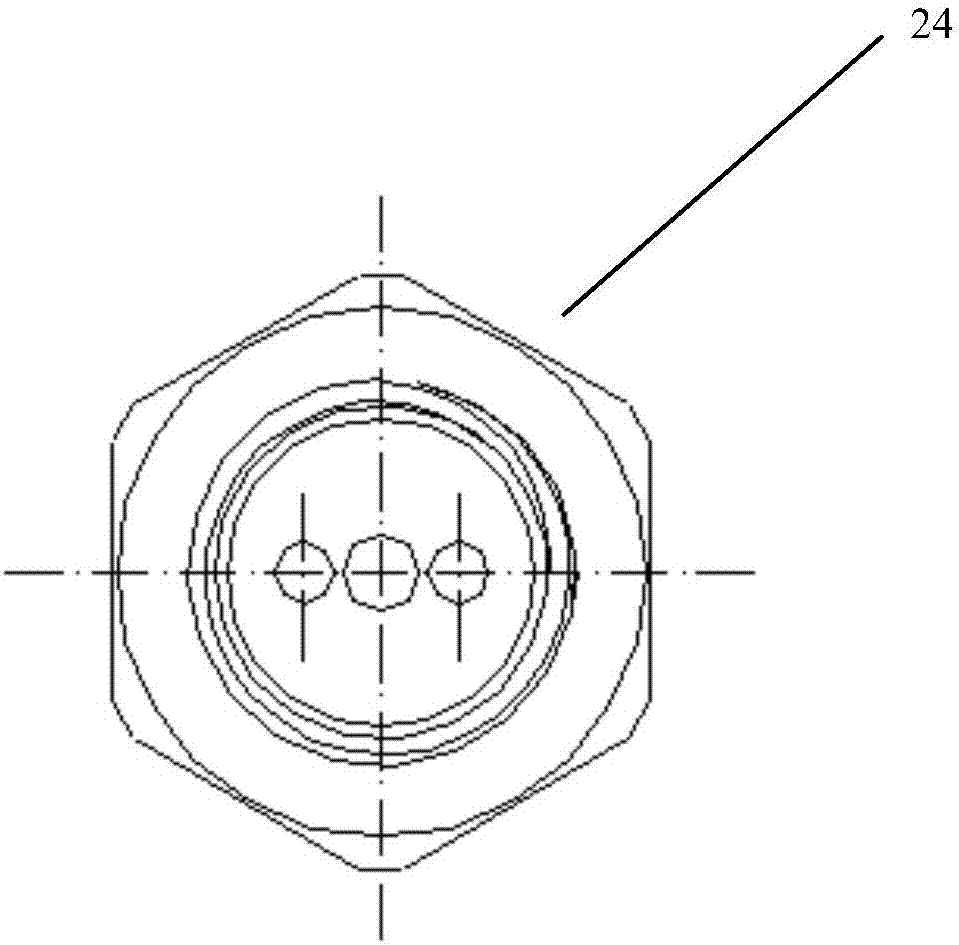

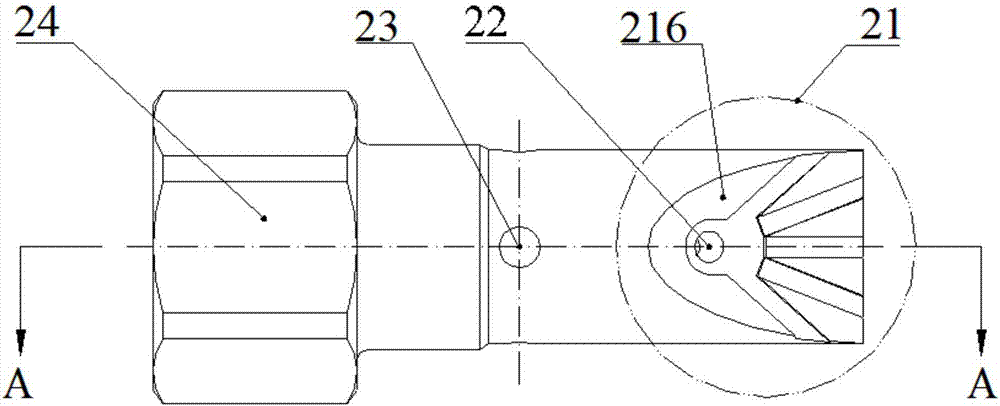

[0127] Fig. 2 is a three-view view of the nozzle body.

[0128] image 3 It is a sectional view of an energy-saving nozzle of a minimal quantity lubrication system.

[0129] Combining Figure 2 and image 3 Description of nozzle body 2:

[0130] The nozzle body 2 includes: diversion groove unit 21, water output hole 22, gas output hole 23, connection fixing unit 24, lubricating oil output hole 25, wate...

Embodiment 2

[0167] Embodiment 2 Compared with Embodiment 1, the lubricating oil and water are mixed instantaneously when they are sprayed out of the nozzle, instead of being mixed inside the nozzle. The change of structure makes the mixing of lubricating oil and water more fully, and achieves better spray effect.

[0168] To sum up, the present invention is applied to the supply of micro-quantity lubricating oil and water, which realizes the uniform lubrication of the line contact processing form, solves the application bottleneck of the existing nozzle point lubrication, improves the efficiency of the three-phase flow oil, water and air supply, and effectively reduces the The problem of pollution to the working environment provides a new way for the high-efficiency, low-carbon, and energy-saving applications of minimal quantity lubrication.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com