A turbo expander with uniform liquid separation function and refrigeration system

A turbo-expander, evenly divided technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of uneven liquid separation of liquid separators, non-recovery of throttling expansion work, etc., to reduce the number of equipment, Improve heat transfer performance and reduce irreversible losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

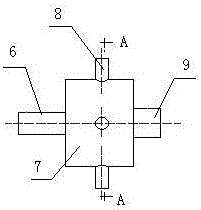

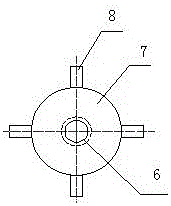

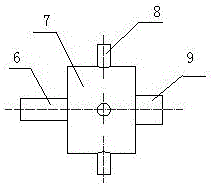

[0024] The schematic diagram of the turboexpander with uniform liquid separation function of the present invention is as Figure 1-Figure 4 As shown, it includes a cylindrical distribution body 7, and the distribution body 7 is provided with a central liquid supply chamber 12 and an annular distribution chamber on the circumference, and the annular distribution chamber is divided into a plurality of distribution chambers 11 by partitions 10 Each of the distribution chambers 11 is connected with a liquid distribution pipe 8, and the center of one end face of the distribution body 7 is installed with a high-pressure refrigerant liquid supply pipe 9 communicating with the liquid supply chamber 12 in the center. A freely rotating rotating shaft 6 passing through the other end surface of the distribution body is installed inside the chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com