Micro-reactor and chemical industry production system

A micro-reactor and reaction tube technology, which is applied in chemical/physical/physical-chemical reactors, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as the need to improve the heat transfer effect of microreactors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

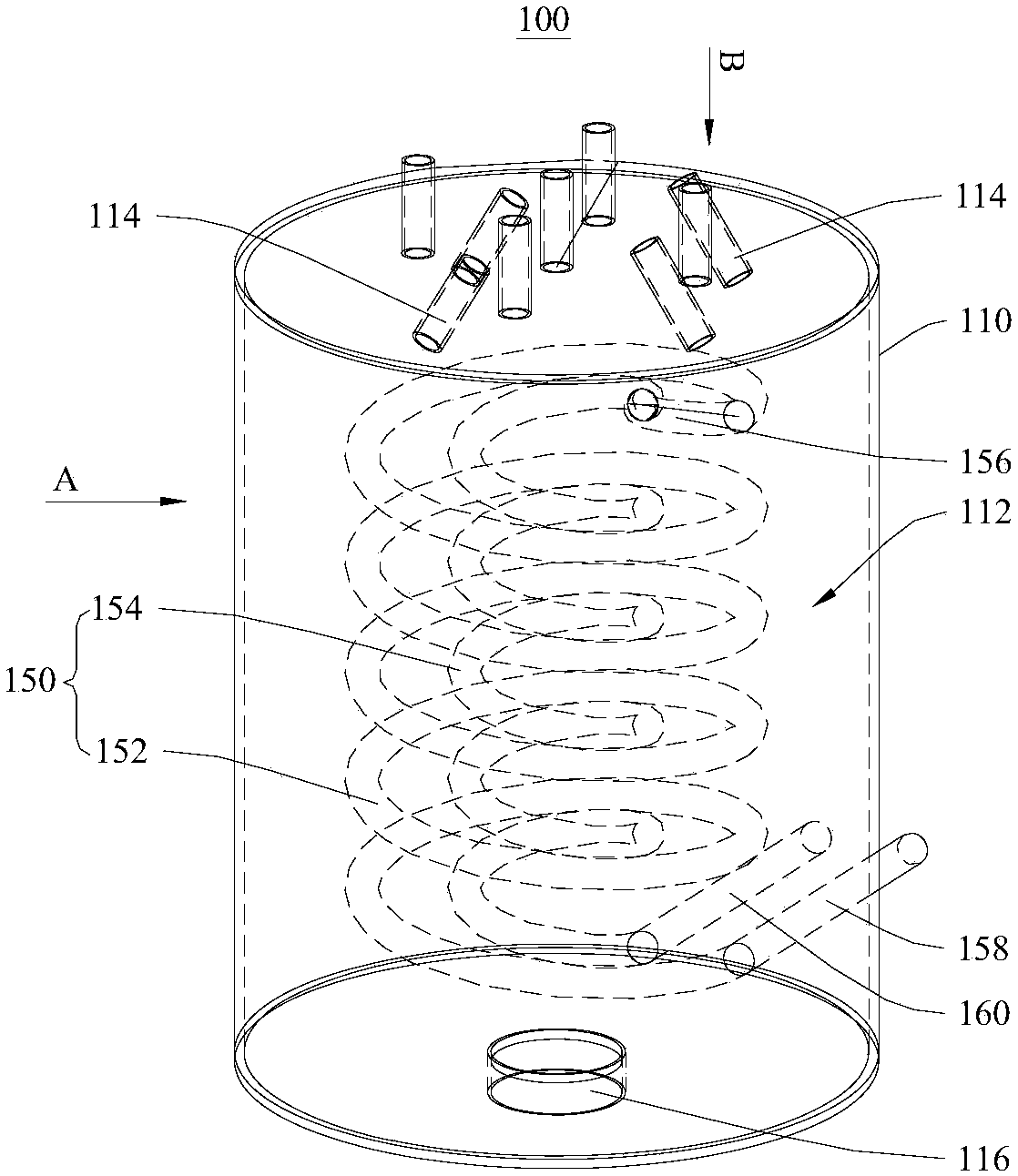

[0036] Please refer to figure 1 , figure 1 Shown is a schematic diagram of the structure of the microreactor 100 . This embodiment provides a microreactor 100, which is mainly used to provide a reaction site and suitable reaction conditions for chemical reactions.

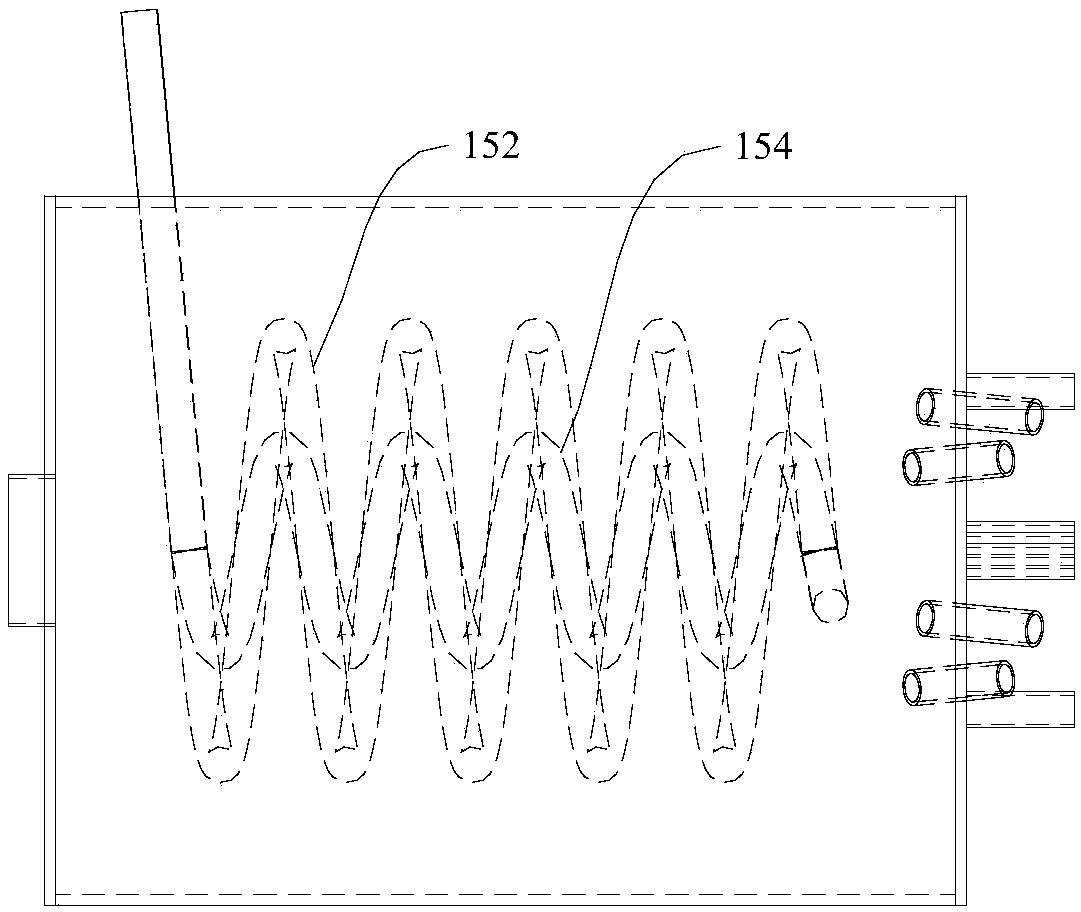

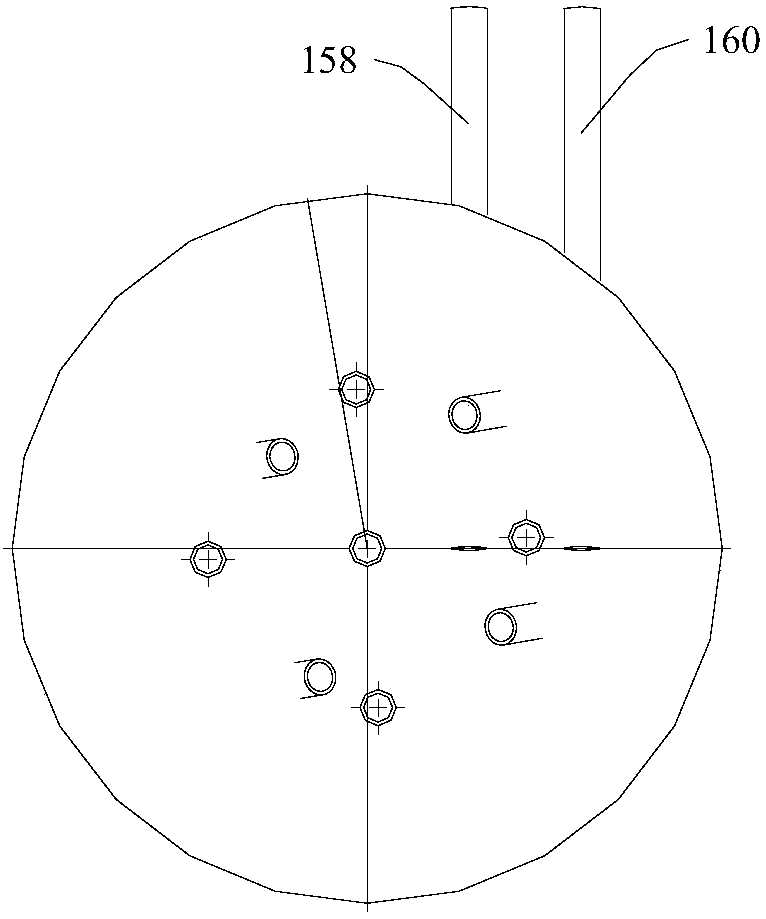

[0037] The microreactor 100 includes a cylinder 110 and a reaction tube 150 connected to each other. The reaction tube 150 is installed in the cylinder body 110 , and both ends of the reaction tube 150 pass through the cylinder body 110 and extend outside the cylinder body 110 , which facilitates the feeding and discharging of the reaction tube 150 . Wherein, the diameter of the reaction tube 150 is generally 3-8 mm.

[0038] In this embodiment, the cylinder body 110 is used to hold the heat exchange medium, and the reaction tube 150 is used to hold the reaction material. The heat exchange medium can be used to raise or lower the temperature of the reaction material, so that the reaction material is at a suitab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com