System and method for measuring temperature of friction pair of wet clutch

A wet clutch and temperature measurement technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems that the predicted value cannot fully represent the actual temperature value, it is not applicable to measure the temperature of the wet clutch, and the wet clutch has no absolute reliability. Achieve the effects of easy implementation, ensuring high-speed and accurate transmission, and preventing failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

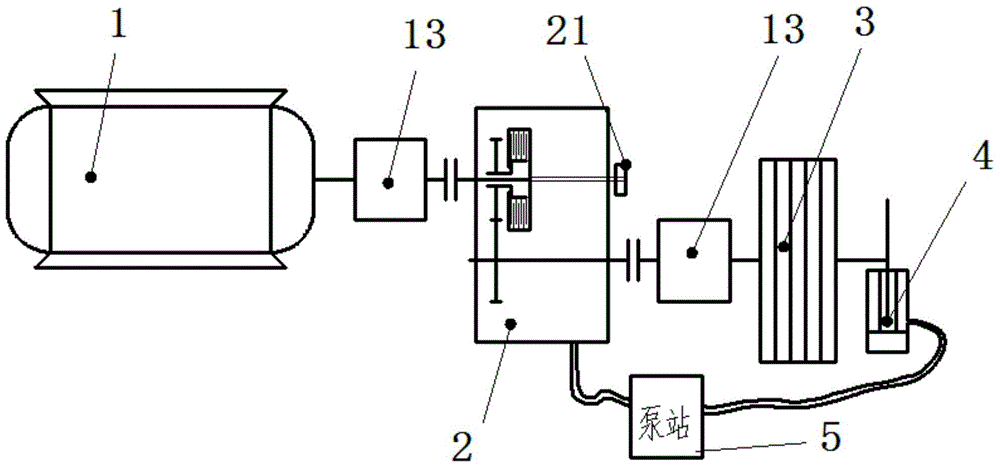

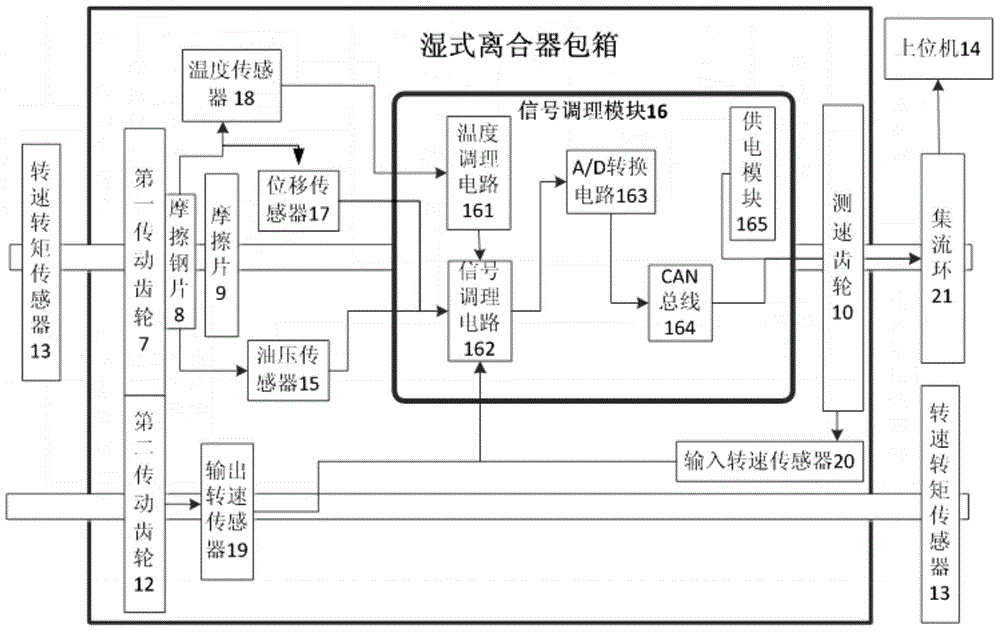

[0020] Such as figure 1 , figure 2 As shown, the present invention provides a wet clutch friction pair temperature measurement system, which includes a power transmission system and a data acquisition system. The power transmission system includes a motor 1, a wet clutch case 2, an adjustable inertia group 3, a hydraulic pressure Brake 4 and a pumping station 5; Among them, the wet clutch box 2 adopts a double-shaft clutch, which is provided with a first transmission shaft 6, a first transmission gear 7, a friction steel plate 8, a friction plate 9, a speed measuring gear 10, a first The two transmission shafts 11 and the second transmission gear 12, and the first transmission shaft 6 and the second transmission shaft 11 all adopt a hollow shaft structure, and the central holes of the shafts are used for arranging data transmission lines in the data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com