Hydraulic two-way splitting rod

A splitting rod and hydraulic technology, which is used in fluid pressure actuating devices, discharging machinery, earth-moving drilling, etc., can solve problems such as uneven force on splitting rods, scrapping of splitting rod equipment, and large vibration of transmission accuracy. , to achieve good splitting effect, improve splitting efficiency and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

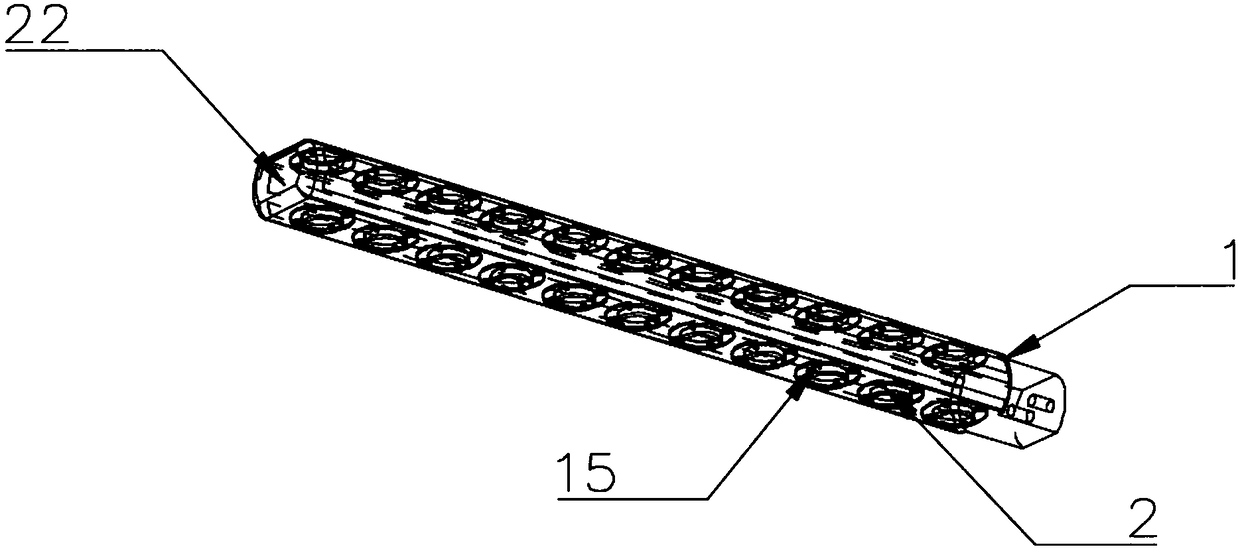

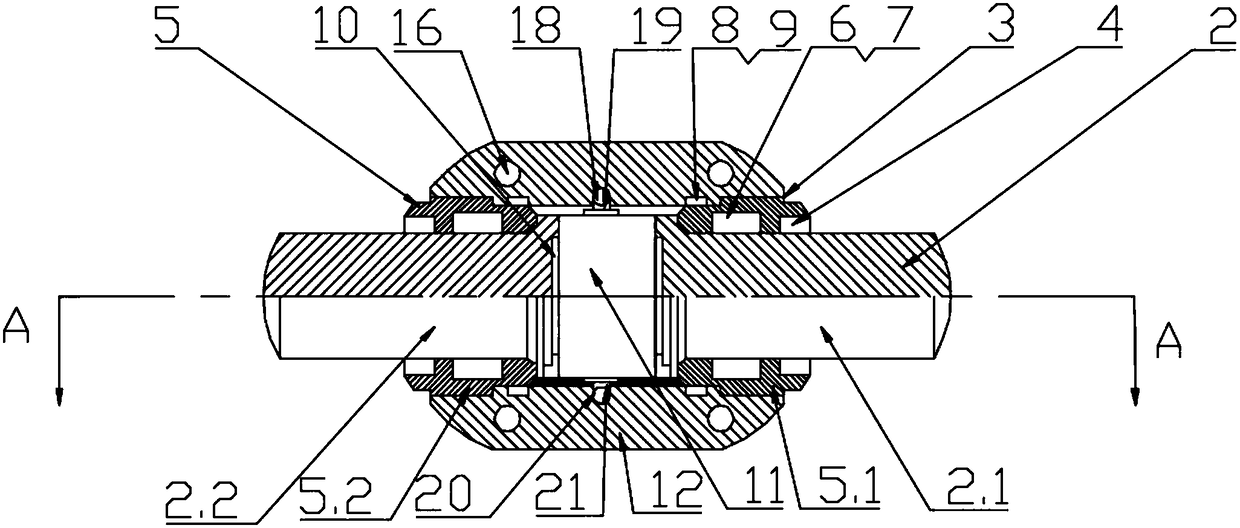

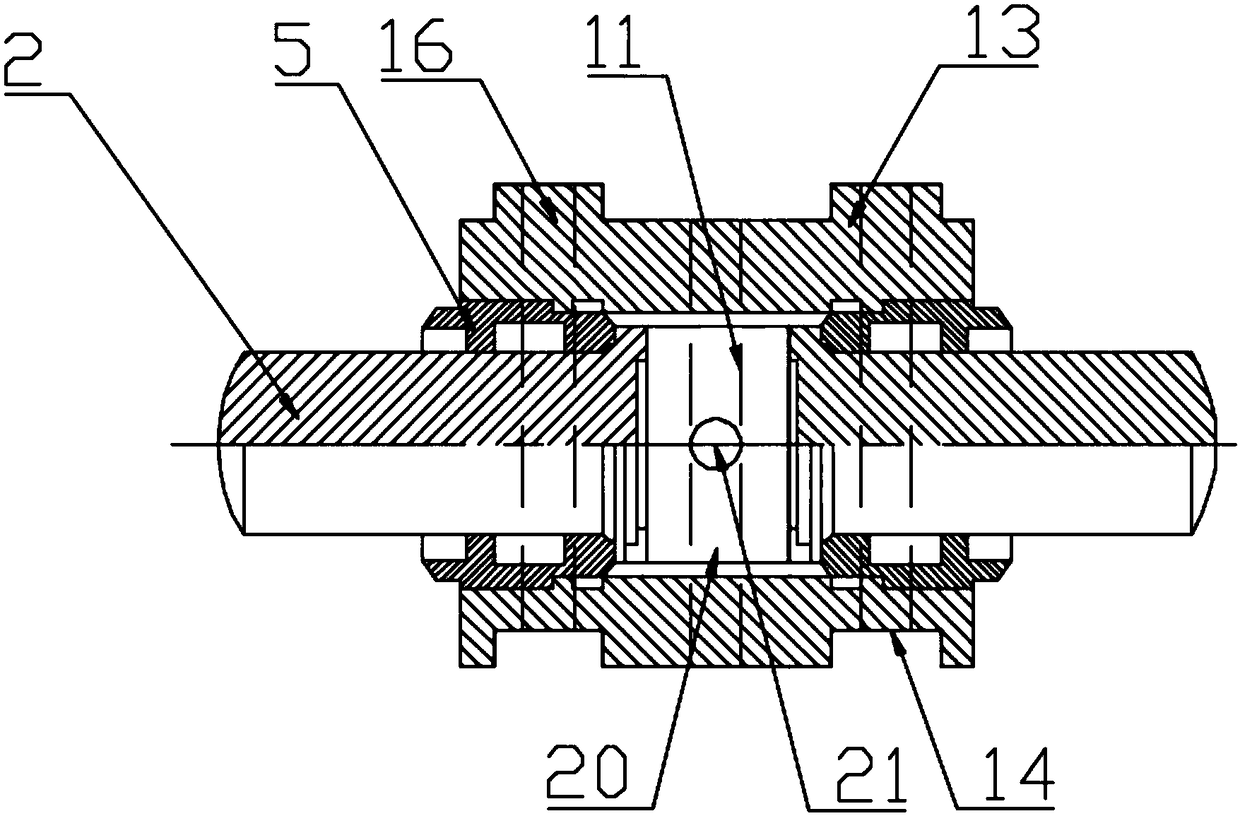

[0024] Such as Figure 1 to Figure 4 As shown, a hydraulic two-way splitting rod comprises a rod shell 1 and a hydraulic cylinder, and the rod shell 1 offers a plurality of through holes 15 that allow the piston rod of the hydraulic cylinder to stretch out; the hydraulic cylinder is a two-way hydraulic cylinder 3, and the rod Both sides of the shell 1 are provided with through holes 15, and a plurality of the above-mentioned two-way hydraulic cylinders 3 are longitudinally arranged in the rod shell 1. The hydraulic cylinder 3 shares the same oil inlet channel 18 and oil return channel 20; the two-way hydraulic cylinder 3 includes a cylinder body 12, a cylinder liner 5, a piston rod 2 and a seal, and the first piston rod 2.1 and the second piston rod 2.2 are symmetrically arranged, and the piston Rod one 2.1 is installed on one side of cylinder body 12 through cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com