Combined jet impeller underwater aeration machine

A combined jet and aerator technology, applied in water aeration, biological water/sewage treatment, water/sludge/sewage treatment, etc. All-weather operation and other problems, to achieve the effect of eliminating hidden dangers, convenient installation and connection, maintenance and repair, and avoiding waste of electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

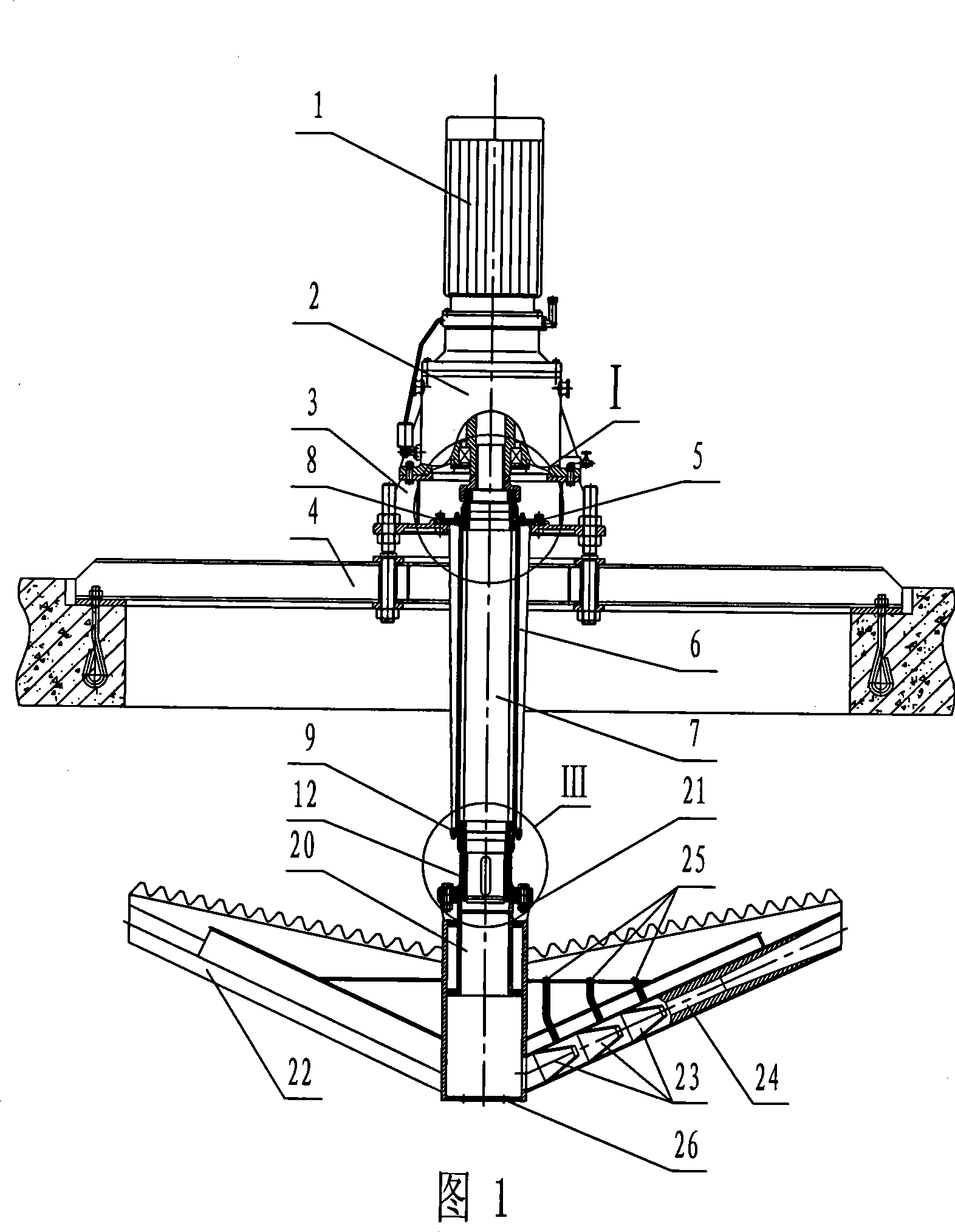

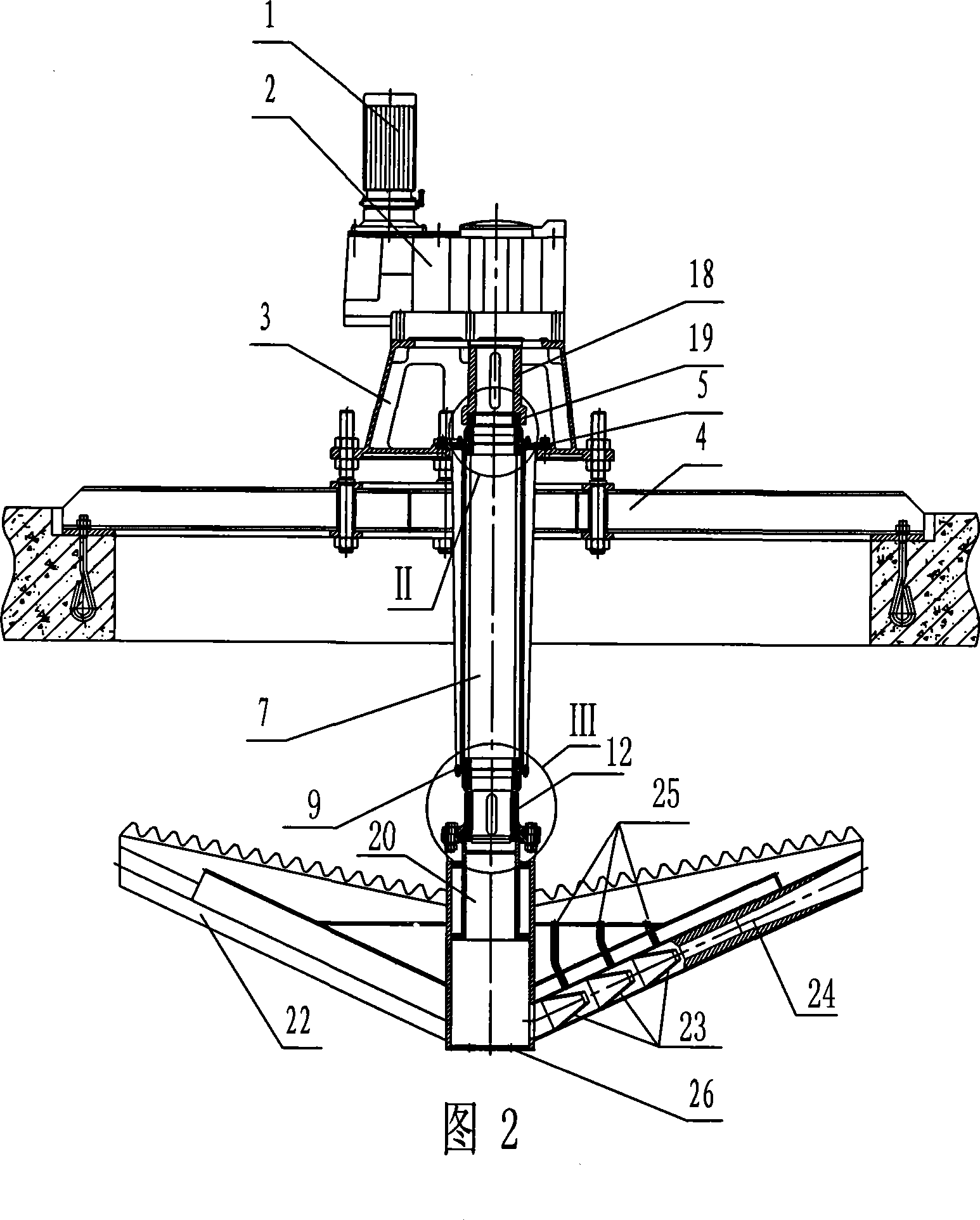

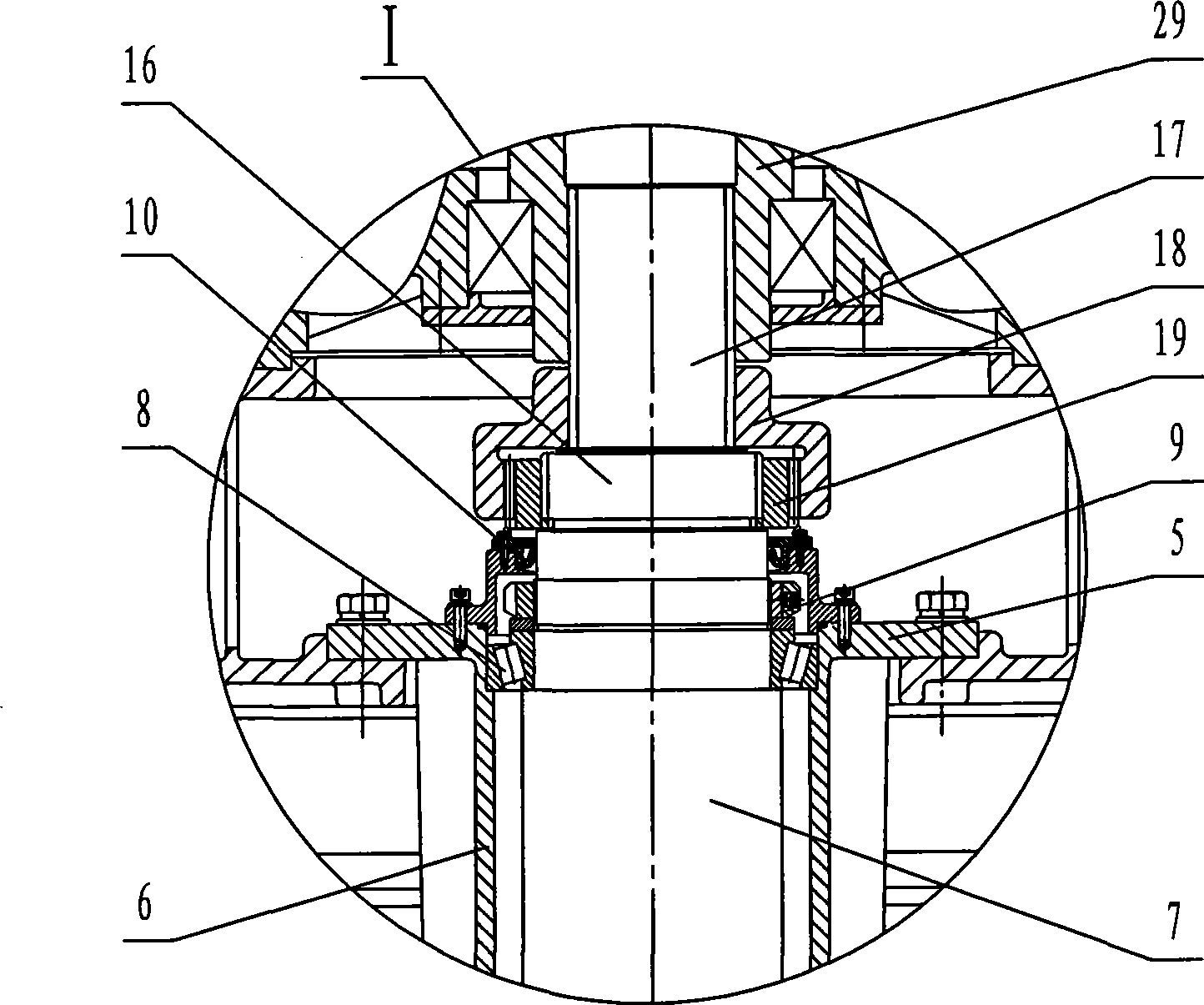

[0028] In Figure 1, Figure 2 and Figure 5Among them, the combined jet impeller underwater aerator of the present invention includes a motor 1, a reducer 2, a mounting beam frame 4, a transmission member and an impeller 20, and the reducer 2 can be an eccentric output shaft reducer or a concentric output shaft reducer, The reducer 2 in Figure 1 is a concentric output shaft reducer, the reducer 2 in Figure 2 is an eccentric output shaft reducer, the motor 1 and the reducer 2 are fixedly connected by bolts, and the blades 22 are fixed on the impeller 20 radially , the bottom of the impeller 20 is provided with a water inlet 26, the bottom of the reducer 2 is provided with a base 3, the upper plane of the base 3 and the reducer 2 are fixedly connected by bolts, and the lower plane is fixedly installed on the installation beam 4, The upper end of the transmission part passes through the base 3 and is slidingly connected with the output shaft of the reducer 2, and the lower end is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com