Rotary blade pump

A technology of rotary vane pumps and rotors, applied in the direction of rotary piston pumps, rotary piston machines, pumps, etc., can solve the problems of fatigue fracture damage, increase the flow rate of oil in and out, and high flow rate of oil in and out, so as to avoid wear and damage of parts , Reduce the flow rate of oil in and out, increase the effect of oil flow in and out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

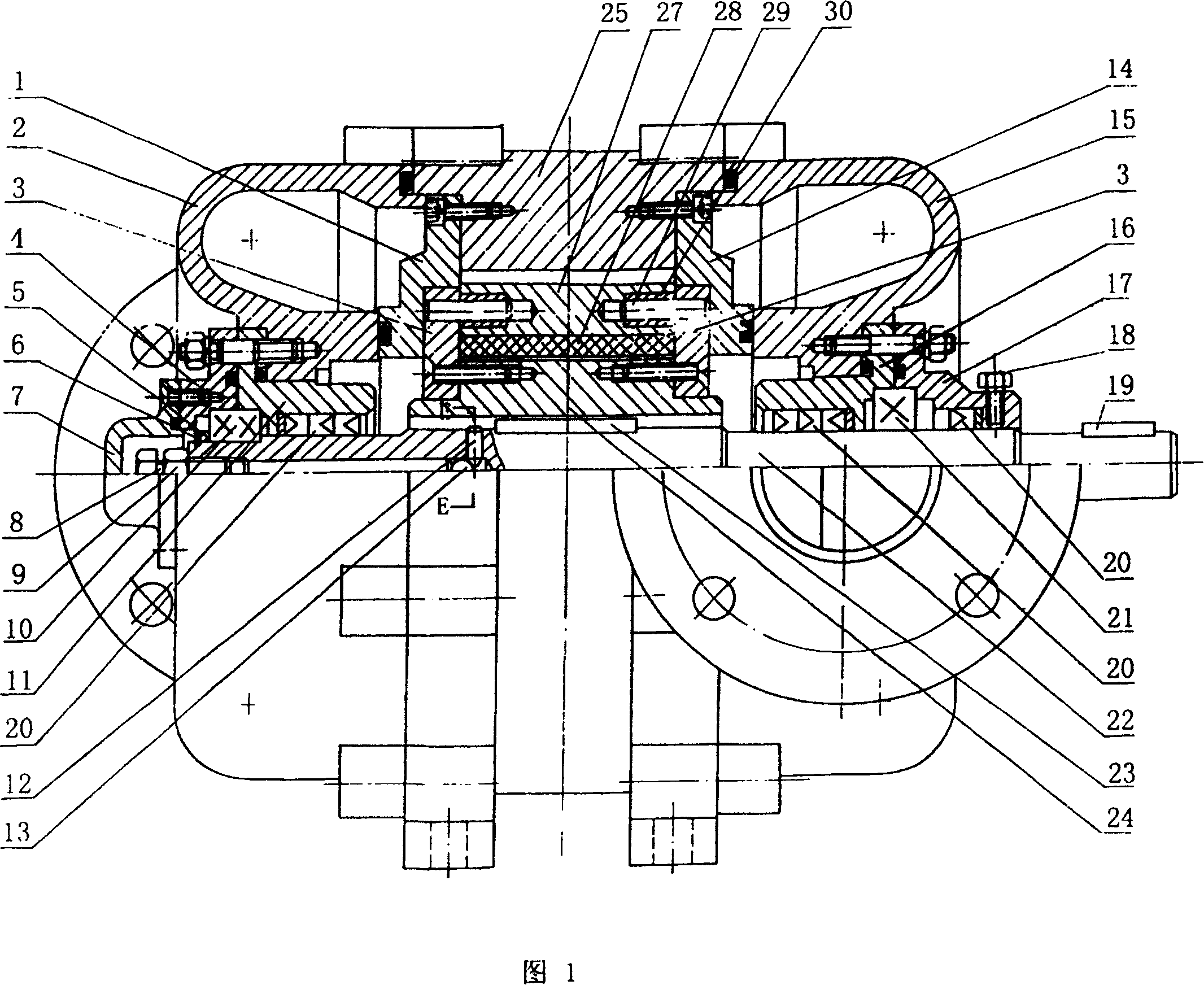

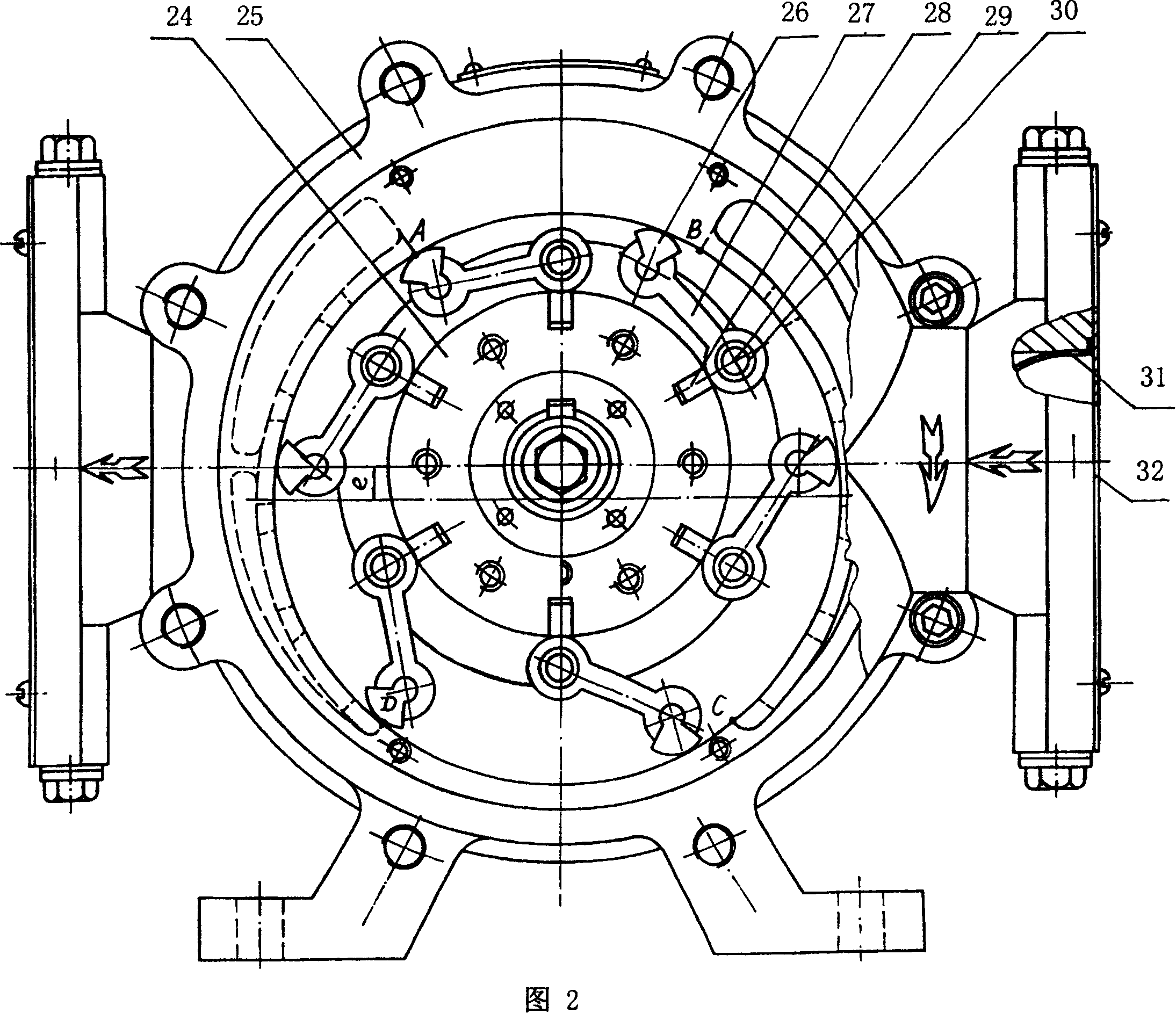

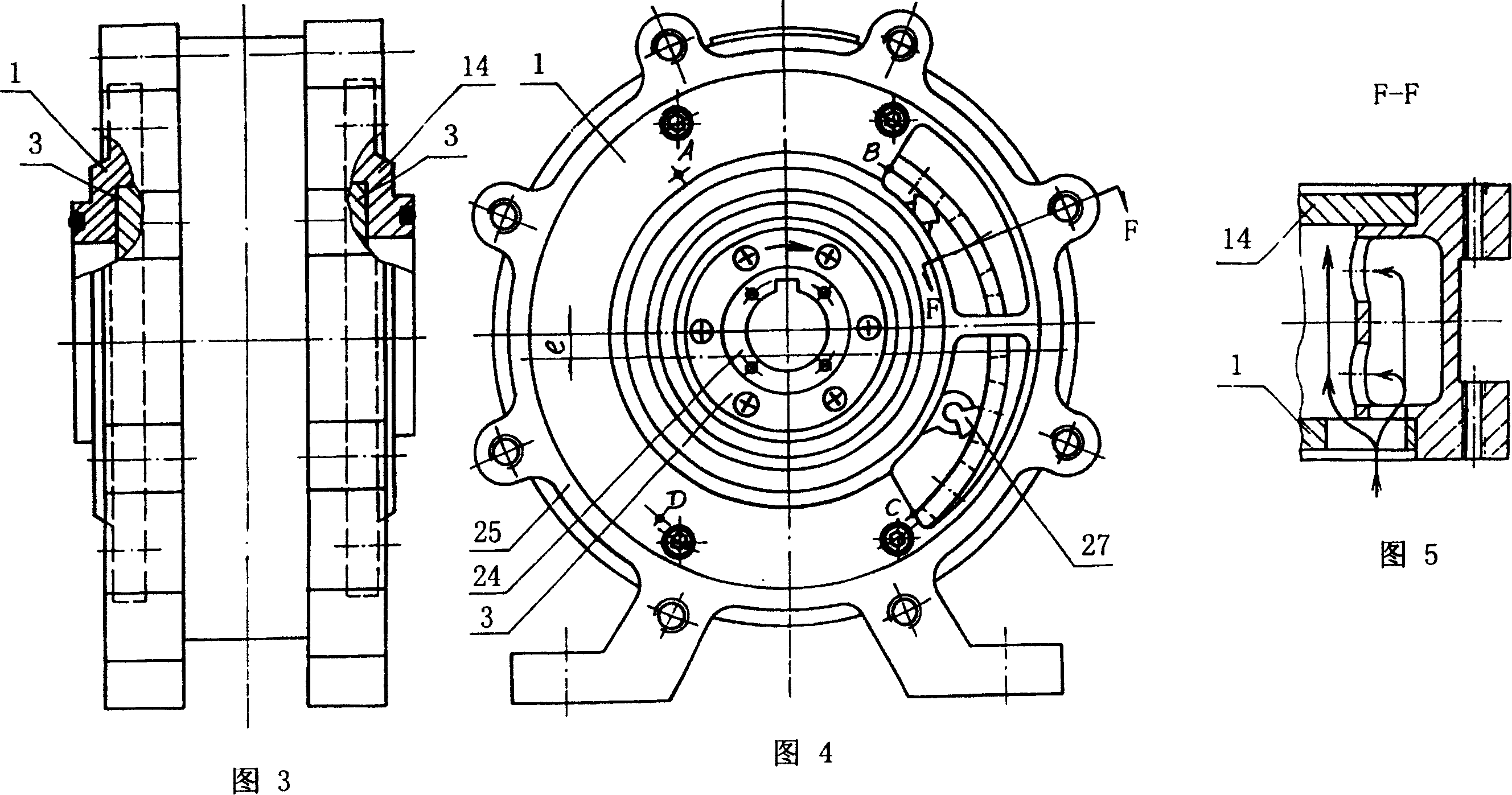

[0028] The invention consists of a stator part, a rotor part, a pump shaft part and a pump cover part. The following points are as follows:

[0029] 1. Stator part

[0030] Including the pump casing stator 25, the oil inlet flow plate 1 and the oil outlet flow plate 14.

[0031] Referring to Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6 and Fig. 7, an oil inlet flow plate 1 is fixed on the front inner end surface of the stator 25 of the pump casing, and an oil outlet flow plate 1 is fixed on the rear inner end surface Plate 14; there is a radial oil inlet passage in the low-pressure oil inlet area of the BC arc section of the pump casing stator 25, and the oil inlet passage communicates with the axial oil inlet window on the oil inlet flow plate 1; the oil inlet flow The axial oil inlet window on the plate 1 also communicates with the inner cavity of the pump casing stator 25; there is a radial oil outlet flow channel at the high pressure oil outlet area of the AD arc s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com