Whole oil tank structure of airplane

An integral fuel tank and fuel tank technology, applied to aircraft parts, wings, internal accessories, etc., can solve the problems of difficult assembly, small deformation capacity, and high manufacturing requirements, and achieve improved fuel utilization, reduced fuel tank residual oil, and reliable sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

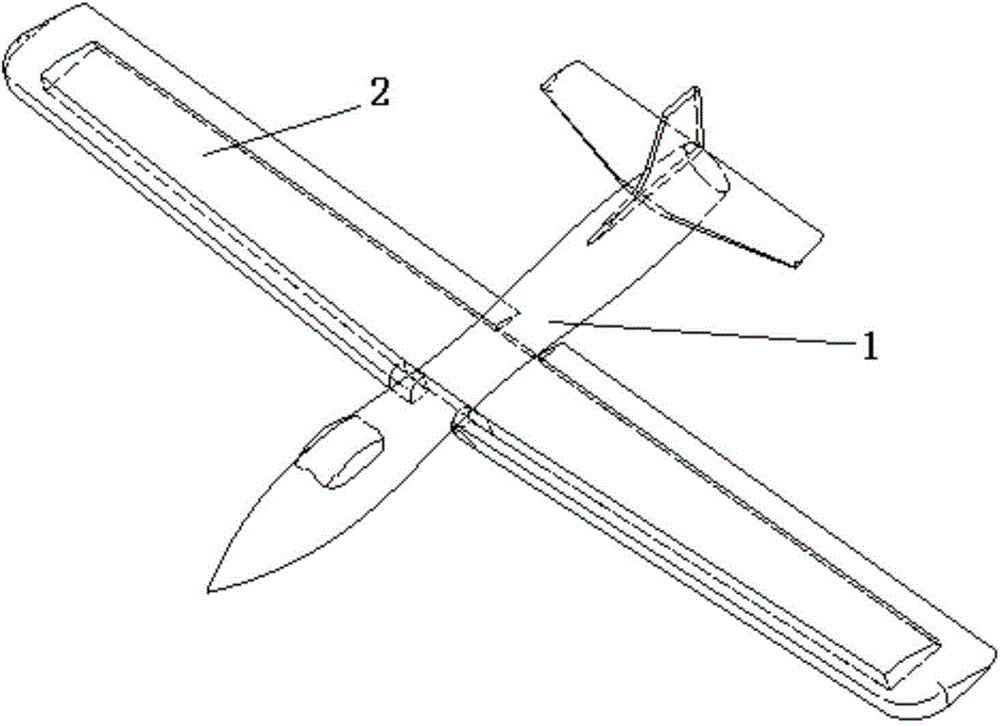

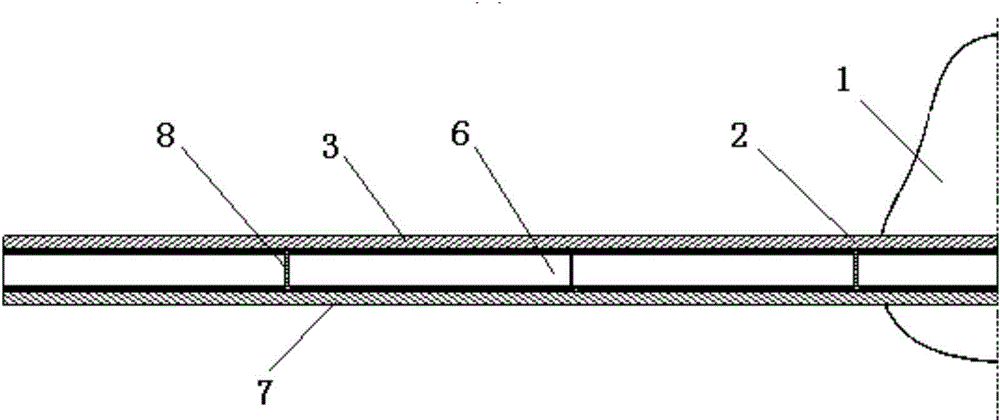

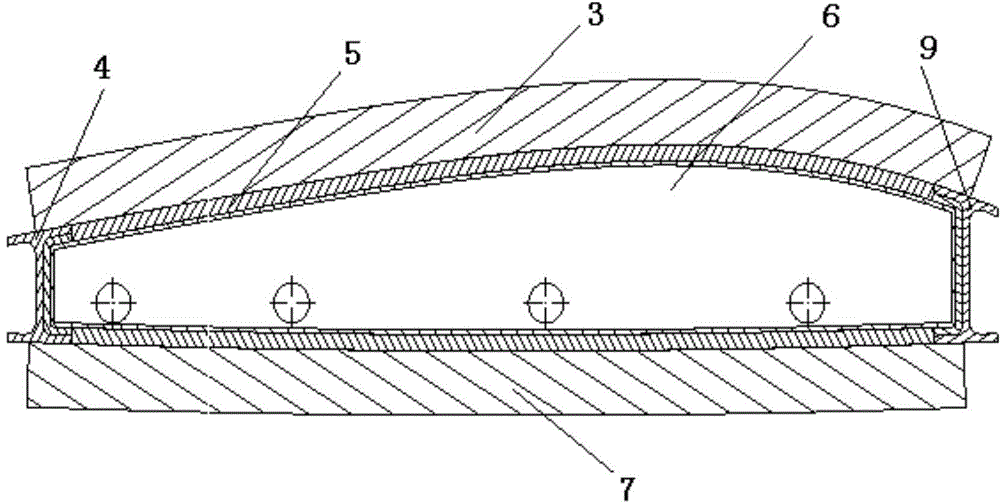

[0028] The integral fuel tank 2 of the aircraft is also called a wing box, and is fixed on the fuselage 1 of the aircraft. The overall fuel tank structure includes a plurality of fuel tank liners 6 made of composite materials, a front beam 9, a rear beam 4, an upper wall plate 3 and a lower wall plate 7, and the fuel tank liner 6 is located between the upper wall plate 3 and the lower wall plate 7 , the front beam 9 and the rear beam 4 are respectively connected to the front edge and the rear edge of the upper wall plate 3 and the lower wall plate 7, and there are reinforcing ribs 8 prefabricated with composite materials between the fuel tank liner 6, and the fuel tank liner 6 is The sealed container prefabricated by composite materials, the outer wall of the fuel tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com