Clamp for detecting of automobile covering part

A technology of automobile covering parts and fixtures, which is applied in the field of machinery, can solve the problems of inability to make fine adjustments, lack of shock-absorbing devices, and low degree of automation, and achieve the effects of simple structure, convenient clamping work, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

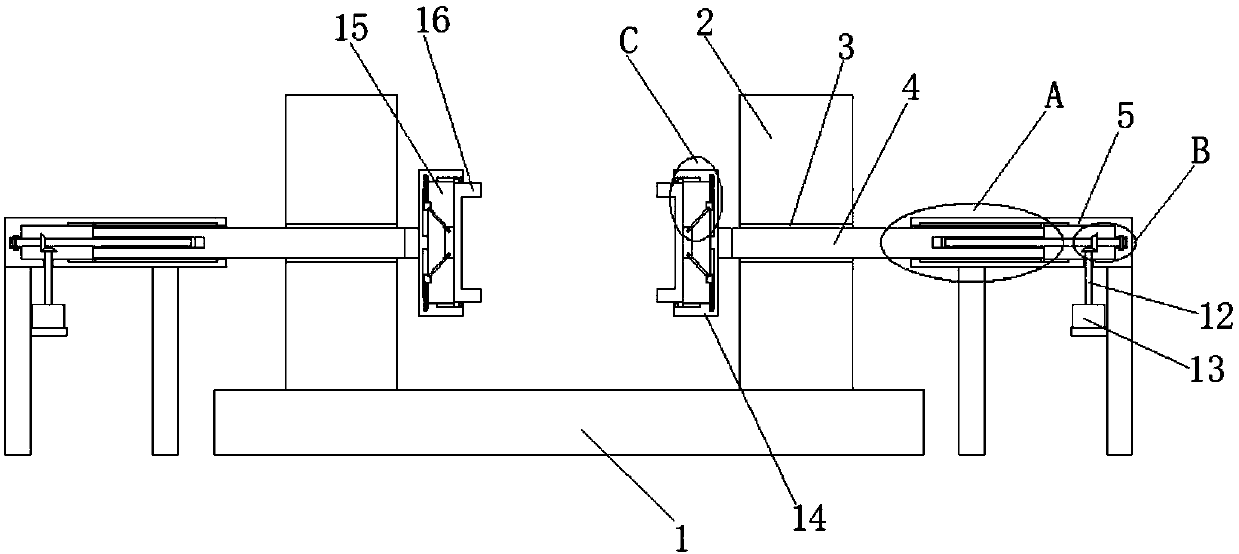

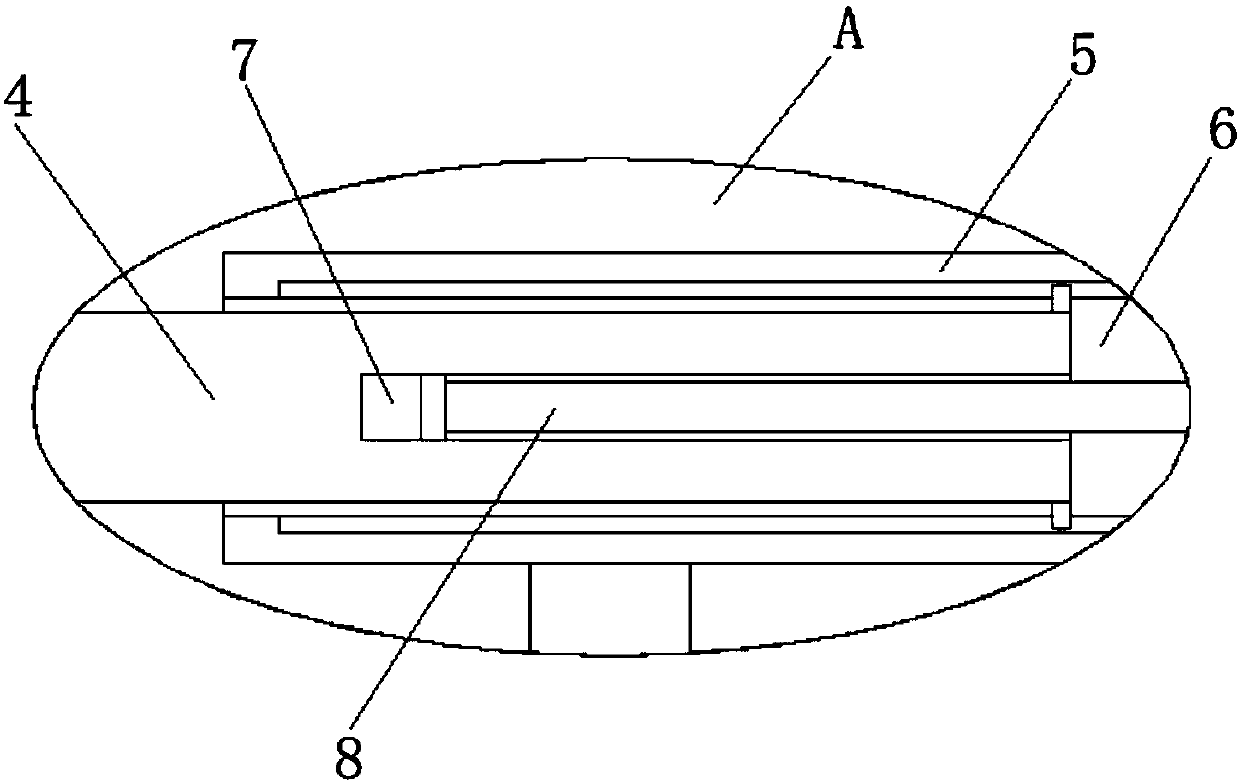

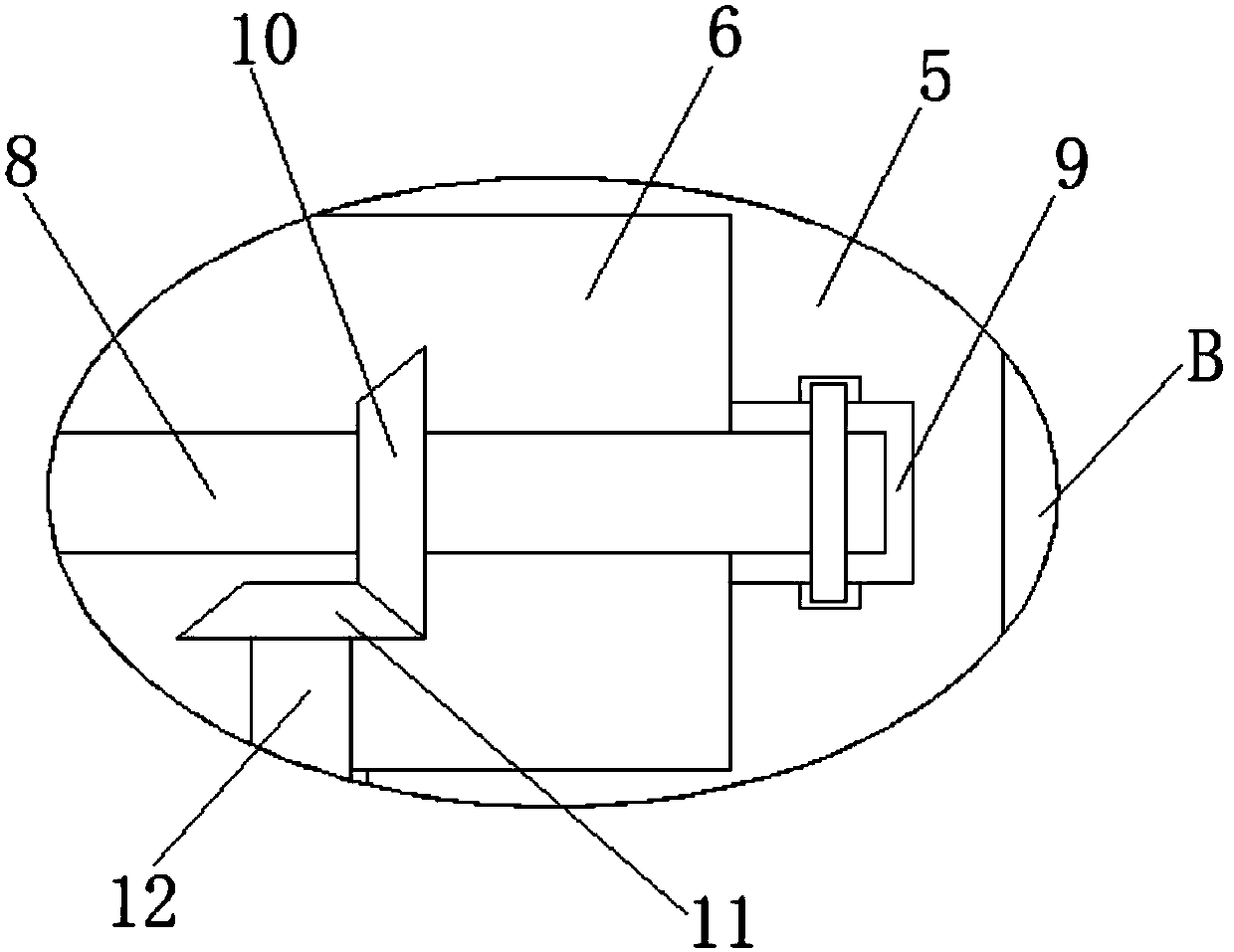

[0027] refer to Figure 1-5, a kind of jig for automobile cover detection, comprising a fixed seat 1, two fixed rods 2 are welded on the top of the fixed seat 1, a connecting rod through hole 3 is opened on the fixed rod 2, and a connecting rod through hole 3 is slidably installed with a connecting rod. rod 4, and both ends of the connecting rod 4 are extended to the outside of the connecting rod through hole 3, both sides of the fixing seat 1 are provided with a fixing block 5, and the side of the fixing block 5 close to the fixing rod 2 is provided with a connecting rod groove 6, The connecting rod groove 6 is slidingly connected with the connecting rod 4, and one end of the connecting rod 4 extends to the outside of the connecting rod groove 6, and the connecting rod 4 is provided with a rotating shaft groove 7 on one side in the connecting rod groove 6, and the rotating shaft groove 7 is installed There is a first rotating shaft 8, and one end of the first rotating shaft 8...

Embodiment 2

[0031] refer to Figure 1-5 , a kind of jig for automobile cover detection, comprising a fixed seat 1, the top of the fixed seat 1 is provided with a welding sleeve, and the top of the fixed seat 1 is welded with two fixed rods 2 through the welding sleeve, so that the fixed rods are firmly welded on the On the fixed seat, the fixed rod 2 is provided with a connecting rod through hole 3, and the connecting rod 4 is slidably installed in the connecting rod through hole 3, and the two ends of the connecting rod 4 all extend to the outside of the connecting rod through hole 3, and the fixed seat 1 Both sides are provided with a fixed block 5, and the side of the fixed block 5 close to the fixed rod 2 is provided with a connecting rod groove 6, the connecting rod groove 6 is slidingly connected with the connecting rod 4, and one end of the connecting rod 4 extends to the connecting rod groove 6 Outside, connecting rod 4 is positioned at the side in connecting rod groove 6 and is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com