Automatic turnover device for welding cylindrical lithium ion battery cap assembly

A lithium-ion battery and automatic flipping technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of high labor intensity, low product yield, low efficiency, etc., to improve production fluency and improve clamping Accuracy, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

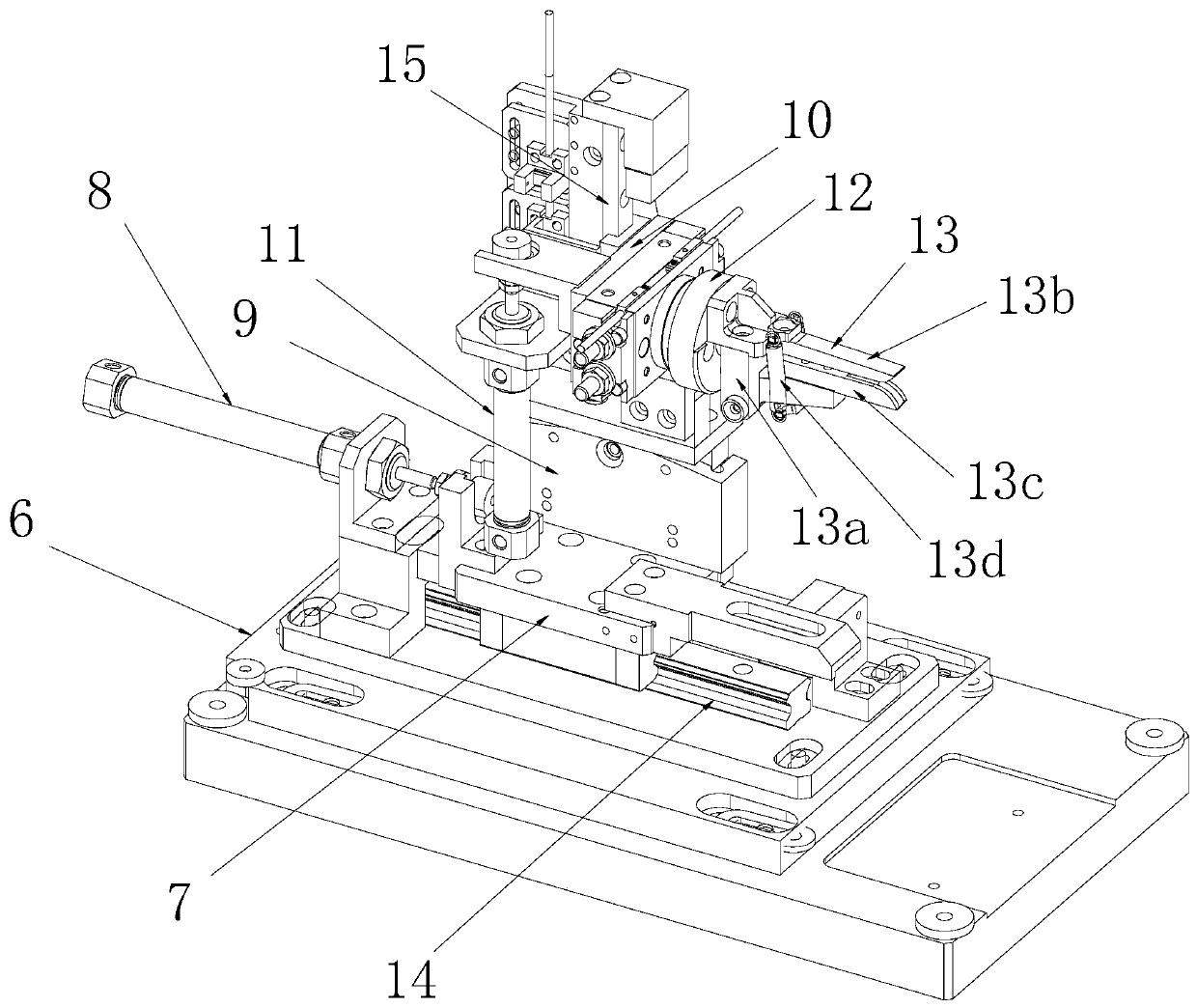

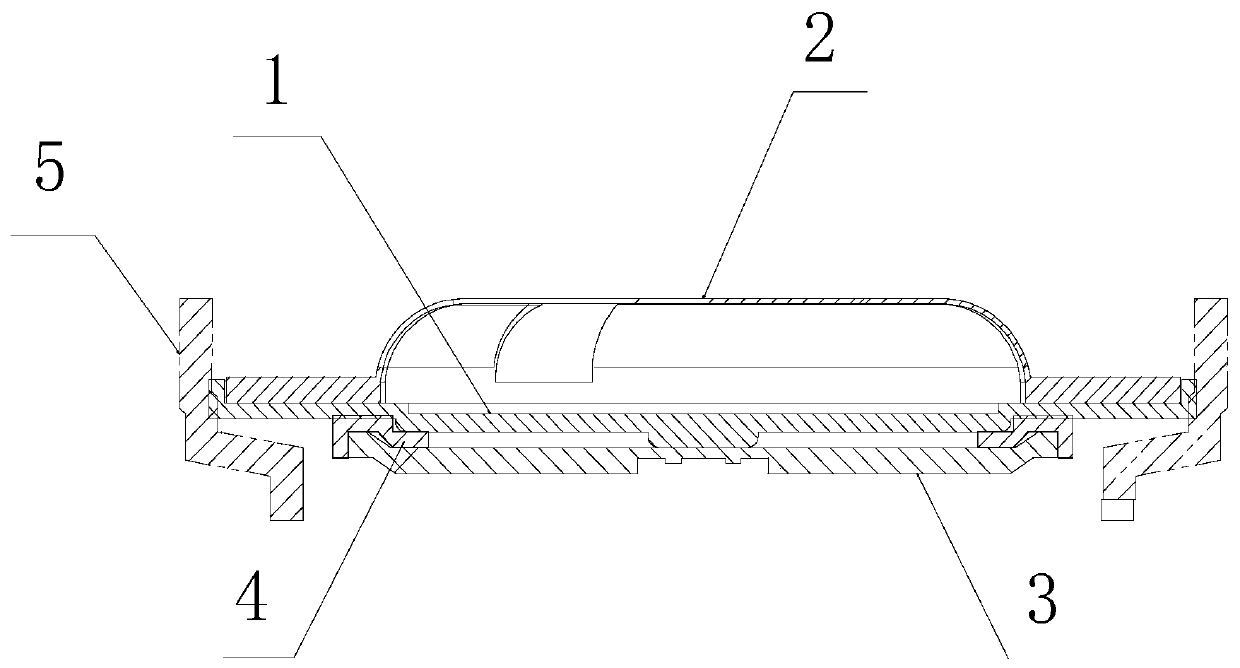

[0022] Example: Combined figure 1 Shown is a specific embodiment of the automatic turning device for welding cylindrical lithium-ion battery cap assembly of the present invention, which is guided horizontally by the base 6, the translation block 7 installed on the base 6 through a horizontal guide mechanism, and the connection driving translation block 7 The translation drive device 8 that moves forward and backward, the support stand 9 fixed on the translation block 7, the lifting block 10 installed on the support stand 9 through the longitudinal guide mechanism, and the lifting block that drives the lift block 10 to move up and down along the longitudinal guide mechanism The driving device 11 , the rotating driving device 12 arranged on the lifting block 10 and the elastic collet 13 driven to rotate by the rotating driving device 12 are jointly constituted.

[0023] The horizontal guide mechanism described in the present embodiment is a horizontal guide rail 14, and the chu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com