Crystal angle adjusting mechanism of automatic X-ray directional bonding machine of round-bar crystals

A technology of angle adjustment and bonding machine, which is applied in the direction of material analysis using radiation diffraction, etc., can solve the problems of difficult real-time and accurate acquisition of crystal movement position parameters, unrealistic transmission accuracy, cumbersome component setting and installation, etc., to achieve Conducive to collection, avoiding errors, and compact connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

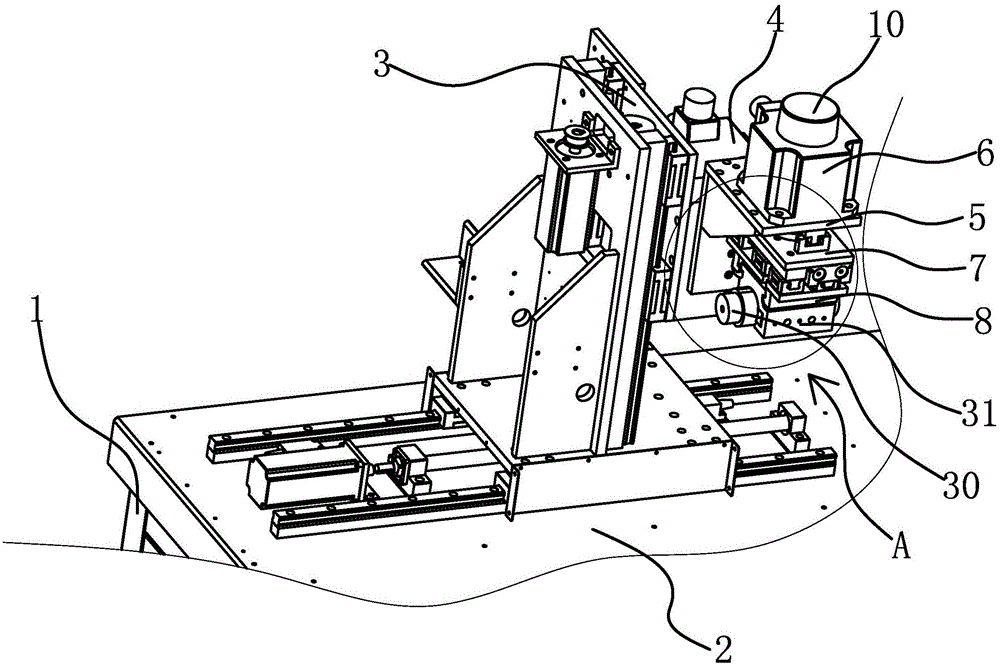

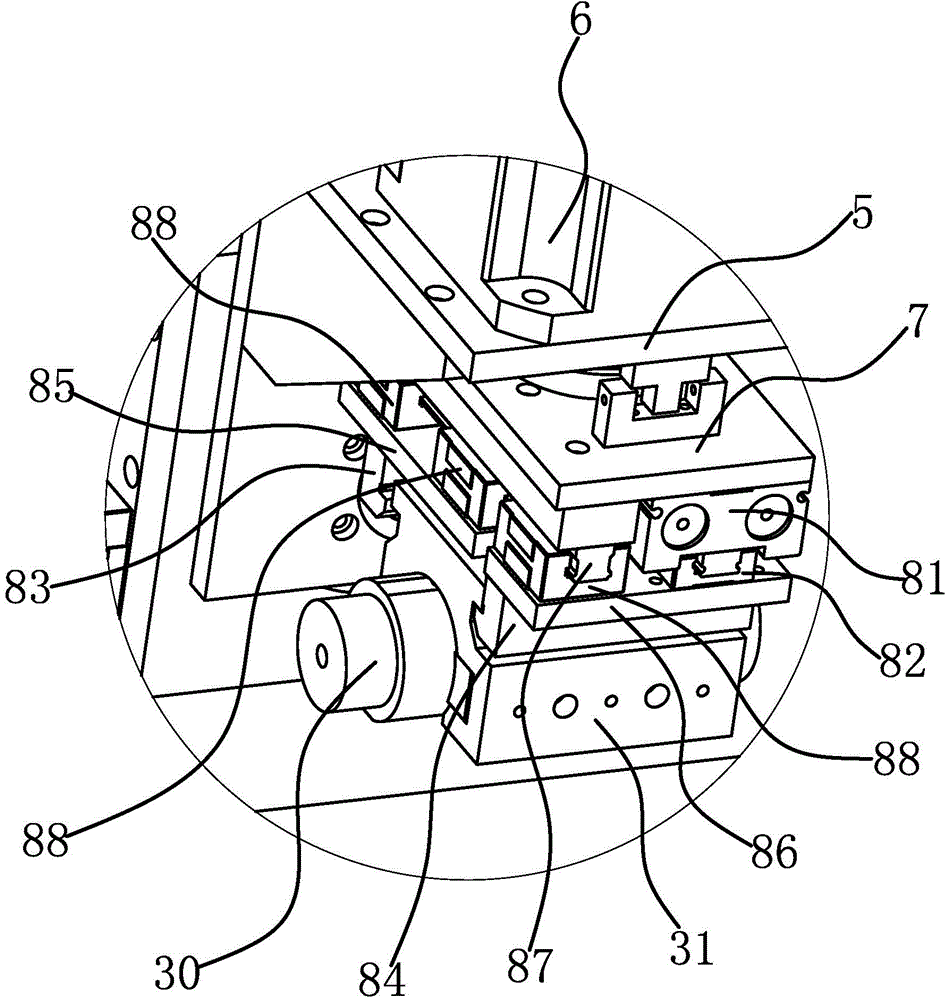

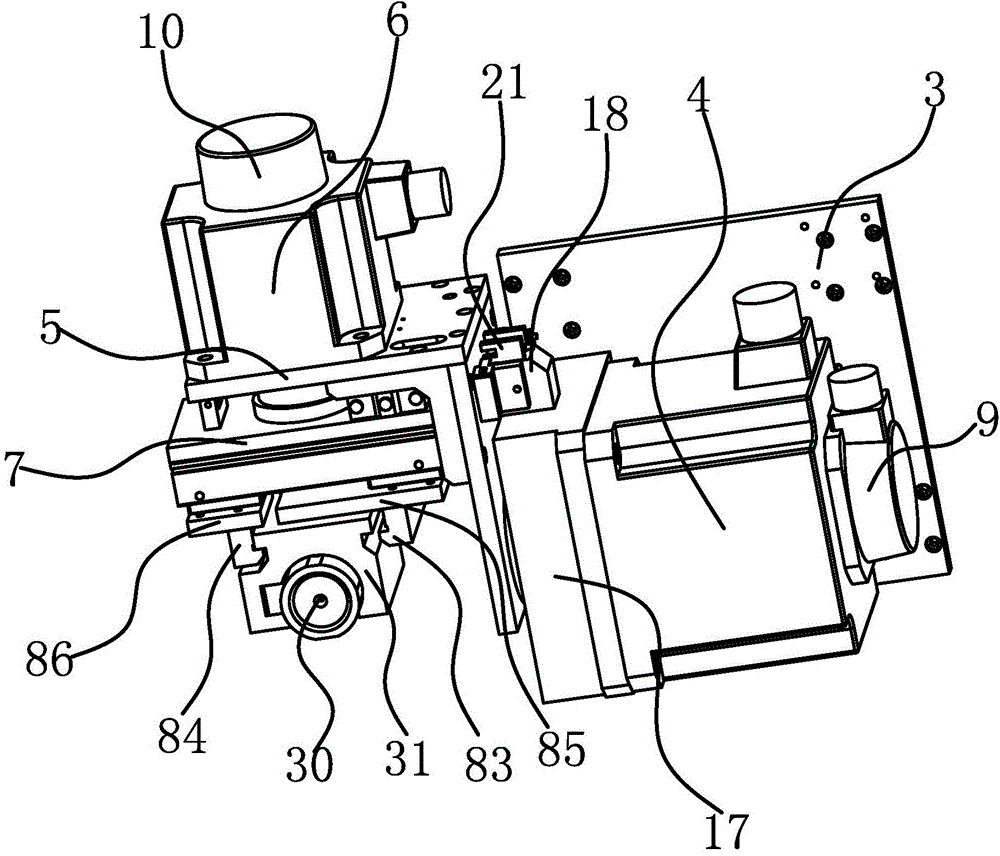

[0033] The round rod crystal automatic X-ray orientation bonding machine is used to detect the diffraction intensity of X-rays at various angles of the round rod crystal, and then calculate the angle of the oriented atomic plane of the crystal to be measured, so as to determine the cutting angle of the round rod crystal. The rod crystal is bonded and fixed while maintaining the cutting angle. The directional adhesive machine includes a frame 1 and a workbench 2. The crystal angle adjustment mechanism of this round rod crystal automatic X-ray directional bonding machine is used to drive the round rod crystal to rotate within the angle range to be measured, and record and feed back the position parameters of the round rod cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com