Piezoelectric MEMS vector vibration sensor sensitive body

A vibration sensor and sensitive body technology, applied in the direction of instruments, measuring devices, electrical devices, etc., can solve the problems of inability to achieve accurate orientation, low orientation accuracy, poor reliability of a single vector vibration sensor, etc., and achieve low power consumption, orientation High precision and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

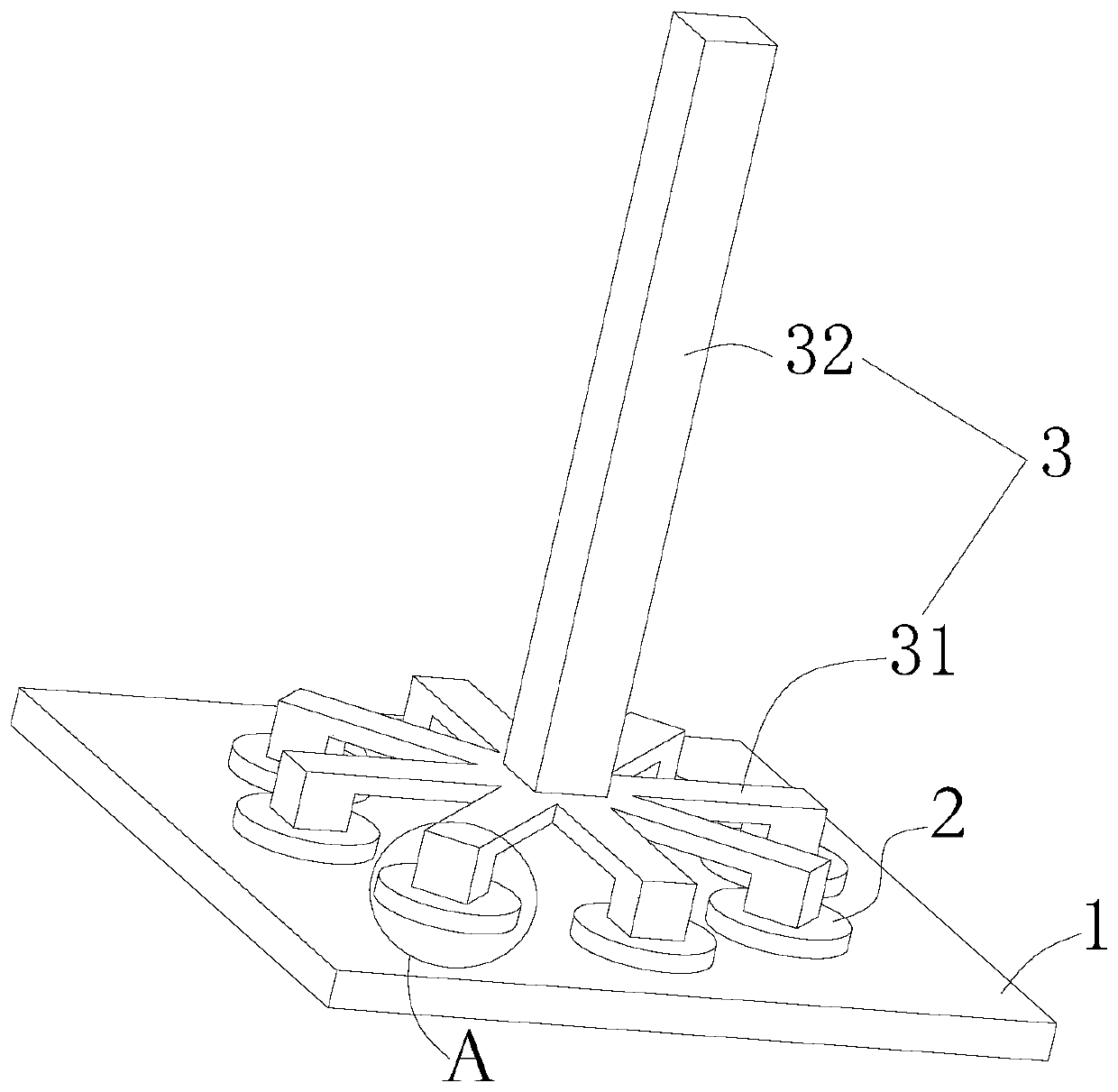

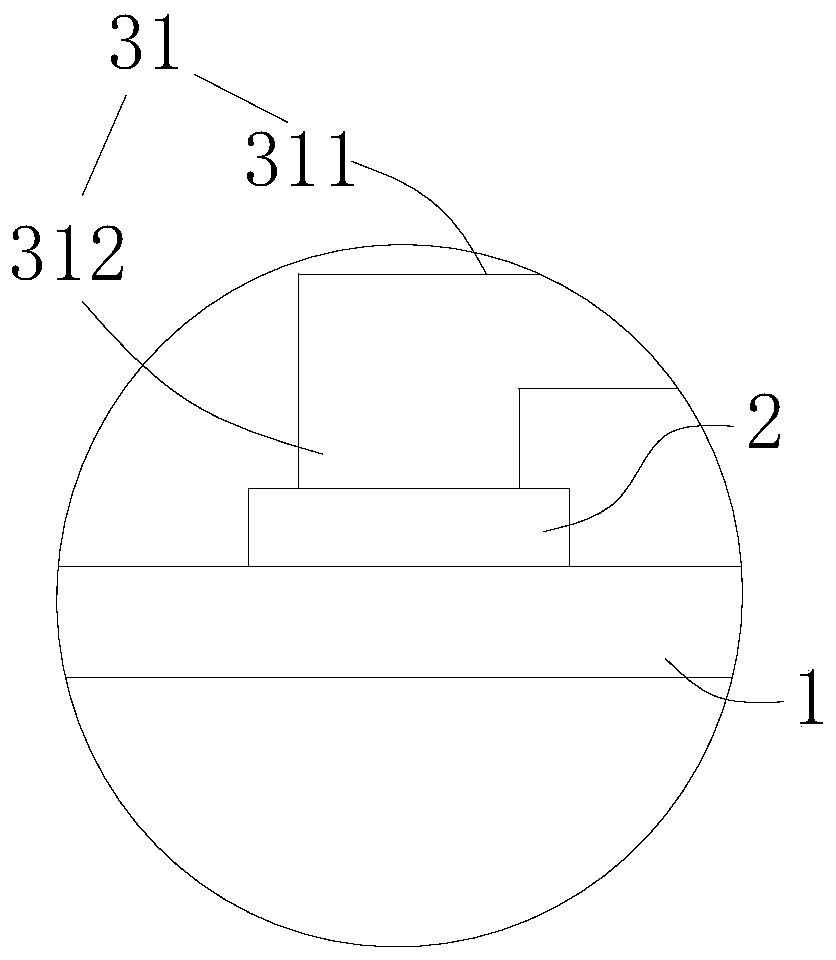

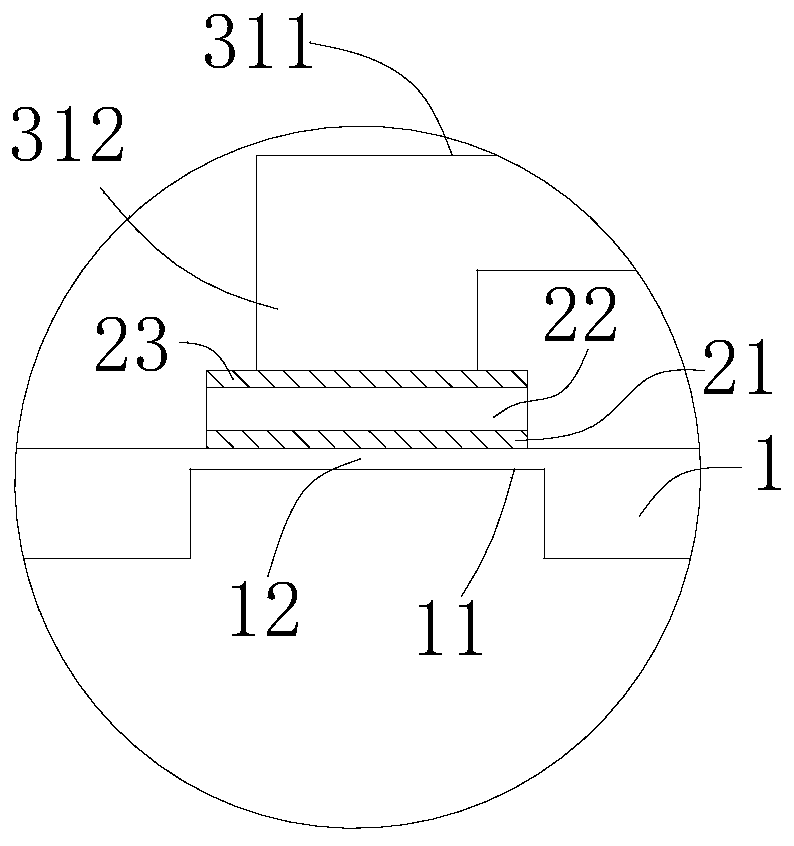

[0025] Such as Figure 1-3 As shown, a piezoelectric MEMS vector vibration sensor sensitive body includes a square silicon substrate 1, and eight circular grooves with exactly the same structural size are evenly etched on the circumference of the square silicon substrate 1 as the center of the circle. 11. A circular thin film layer 12 is formed on the end surface of the square silicon substrate 1 corresponding to each circular groove 11;

[0026] The piezoelectric sensitive unit 2 is arranged on the circular thin film layer 12, and the piezoelectric sensitive unit 2 includes a lower electrode layer 21, a piezoelectric thin film layer 22 and an upper electrode layer 23, and the piezoelectric thin film layer 22 is arranged on the lower electrode layer. Between layer 21 and upper electrode layer 23;

[0027] The piezoelectric sensitive unit 2 is provided with a power transmission unit 3, and the piezoelectric sensitive unit 2 can convert the stress and strain signal received by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com