Substrate clamping device

A technology of substrate clips and substrates, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve the problems of complex transmission structure of the manipulator, large loss of transmission energy-consuming parts, and increase the difficulty of manipulator manufacturing, etc., to achieve a compact structure , Transmission energy consumption and component loss are less, easy to install and flexible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

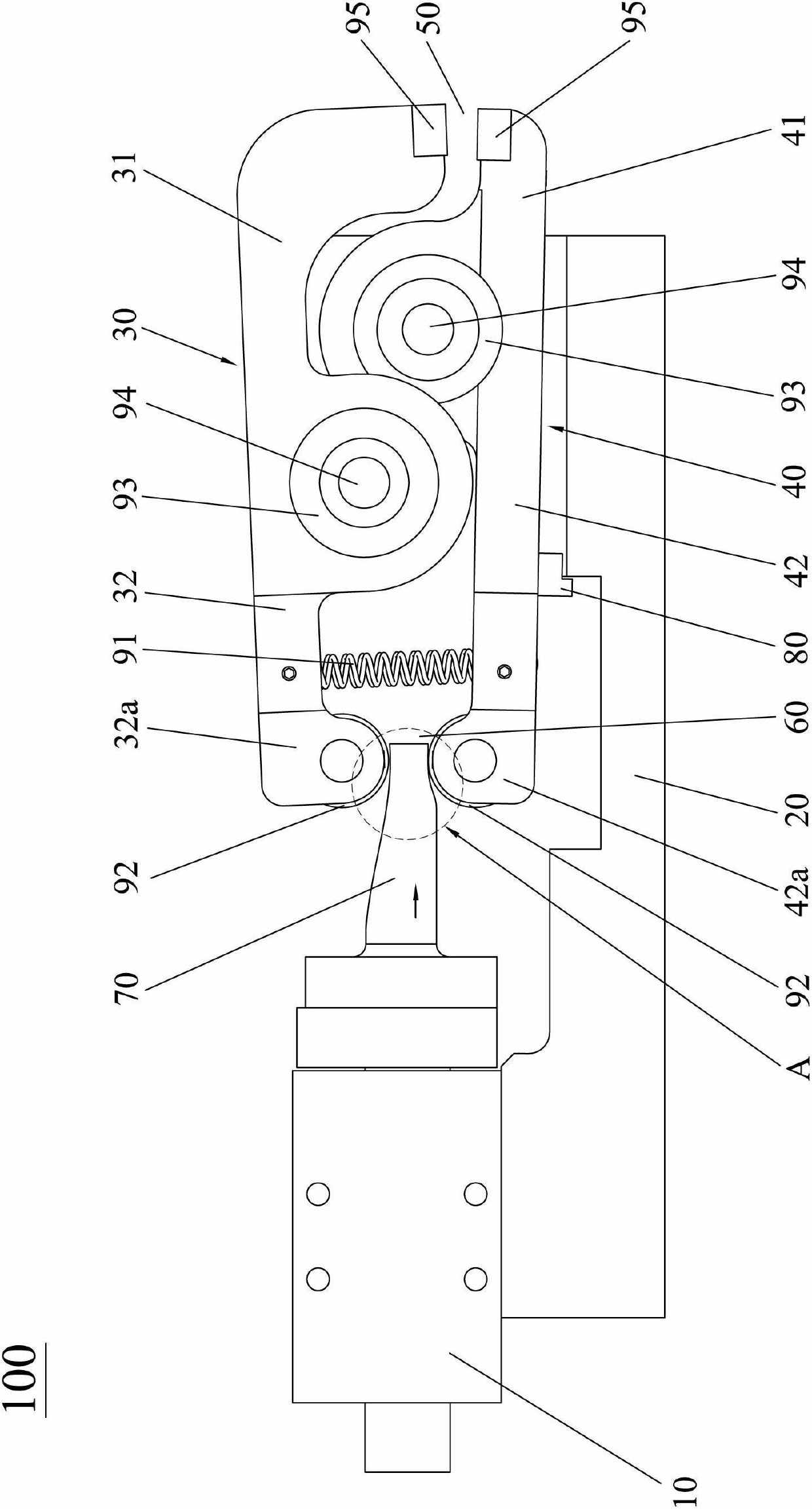

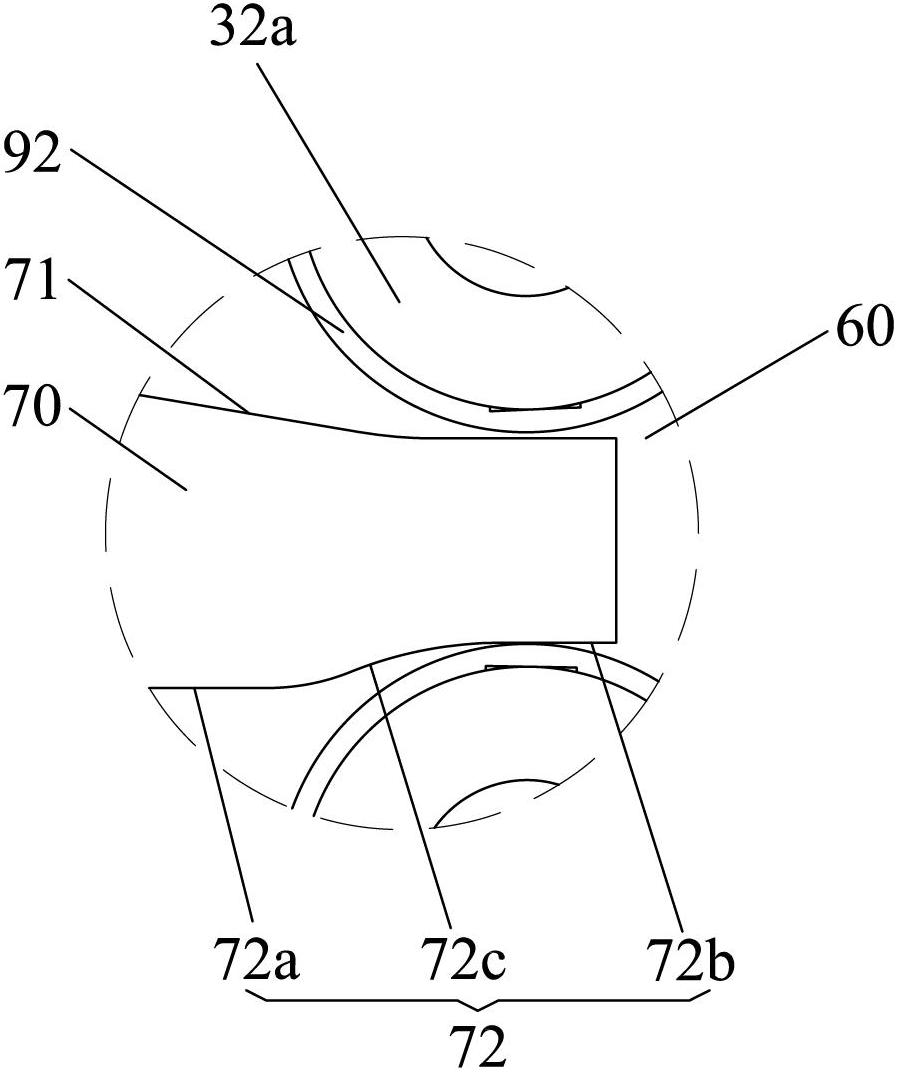

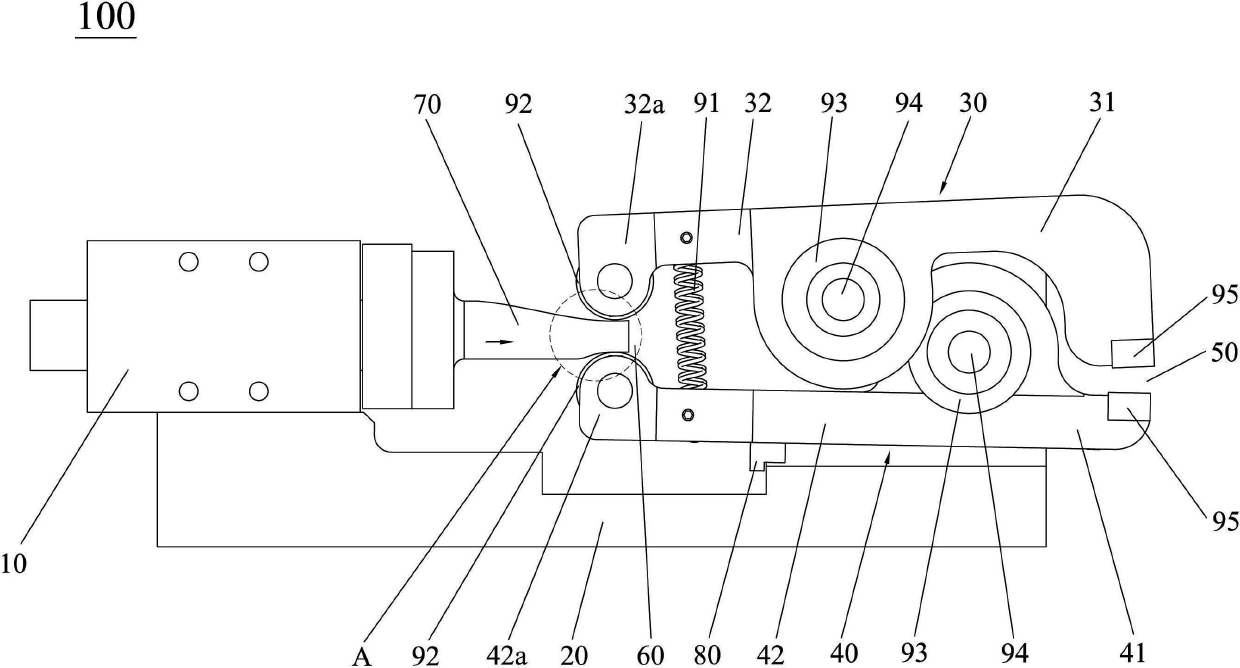

[0019] see figure 1 and figure 2 , the substrate clamping device 100 of the present invention is used for clamping substrates in organic light-emitting displays and solar panels, wherein the substrate clamping device 100 includes a driver 10, a bottom plate 20 and a first clamp that cooperates with each other Fastener 30 and second clamping piece 40. Both the first and second clamping parts 30, 40 are pivotally connected to one end of the bottom plate 20, and the first and second clamping parts 30, 40 each have clamping parts 31, 41 and a pushing part 32 , 42; Specifically, in this embodiment, the first and second clamping members 30, 40 are pivotally connected to the bottom plate 20 in such a way that the substrate clamping device 100 of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com