Clamping mechanism of charge-discharge test device for thin secondary battery

A secondary battery and test device technology, which is applied in secondary battery charging/discharging, secondary battery testing, secondary battery, etc., can solve problems such as cumbersome installation, poor workability, and inability to clamp, so as to reduce cumbersome operations, Effect of reducing workload and improving clamping accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, embodiments of the present invention will be described in detail based on the drawings.

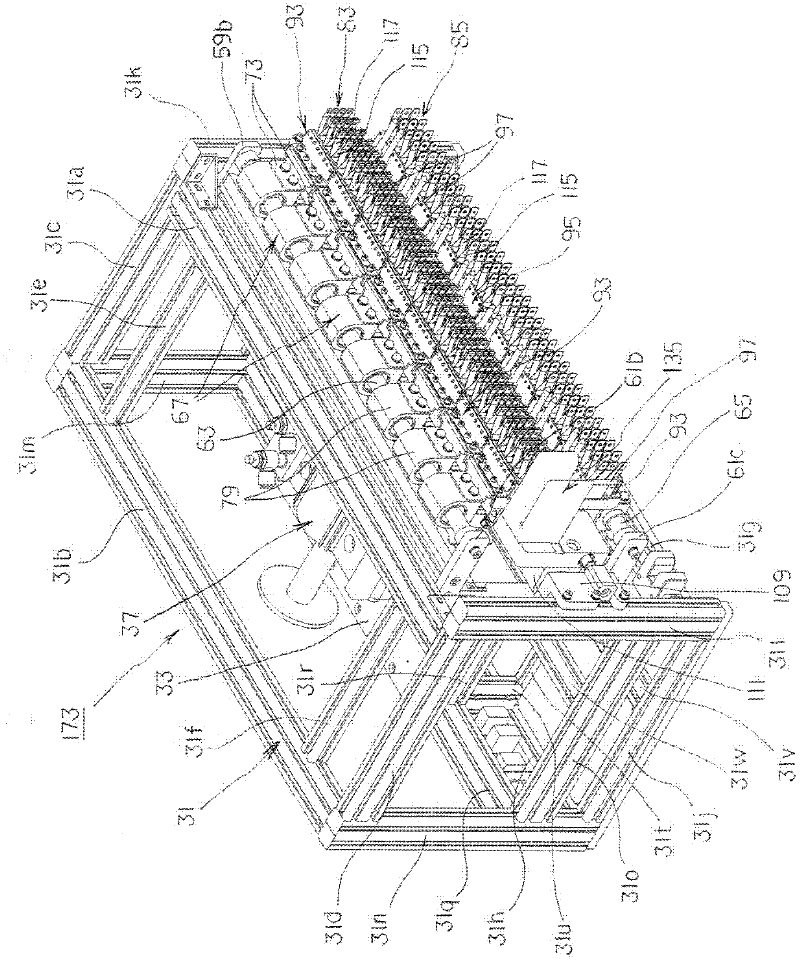

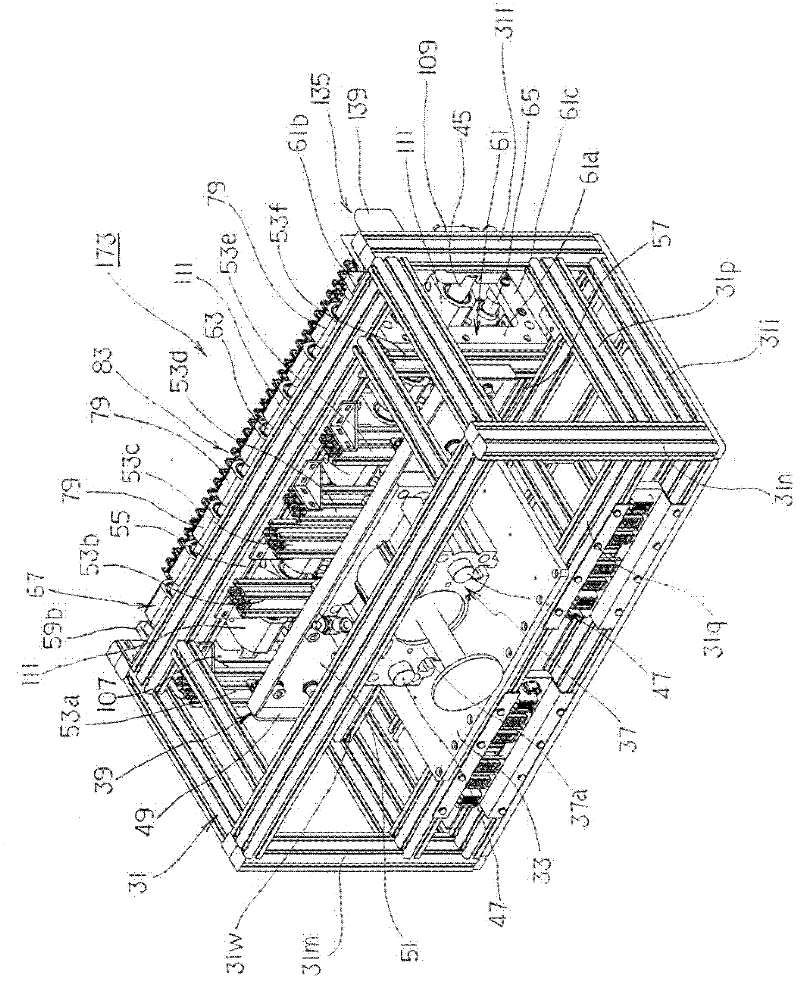

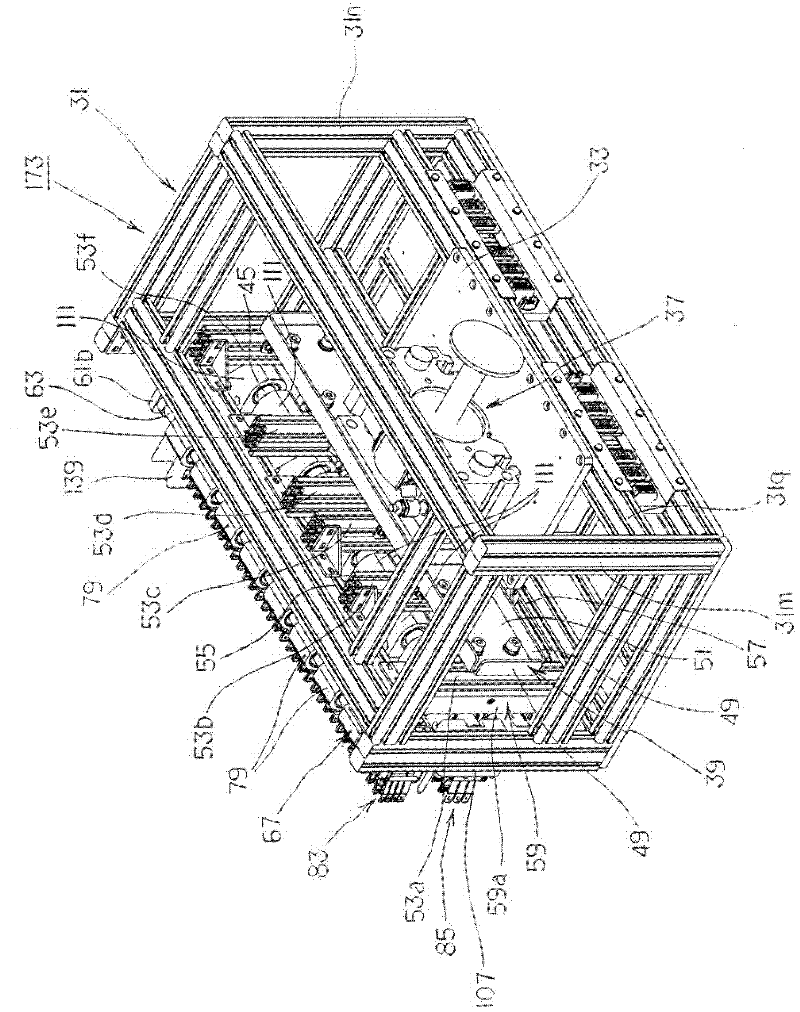

[0044] Figure 1 to Figure 12 The clamping mechanism of the charge-discharge test device for a thin secondary battery according to an embodiment of the present invention is shown. Figure 1 to Figure 5 Among them, 31 is a support base composed of a rectangular parallelepiped frame formed by a plurality of pillars 31 a to 31 w arranged in front, rear, left, and right sides, as figure 1 as well as figure 2As shown, between the pillars 31w spanning between the left and right side pillars 31o, 31p and the pillars 31q spanning between the left and right rear pillars 31m, 31n, a mounting plate 33 having a rectangular shape in plan view is attached. An air cylinder (drive unit) 37 is installed on the loading plate 33, and the air cylinder 37 makes Figure 6 to Figure 9 The illustrated piston rod 35 expands and contracts in the front-rear direction of the support base 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com