High-accuracy intelligent feeding tool

A high-precision, intelligent technology, applied in the direction of conveyor objects, transportation and packaging, furnaces, etc., can solve the problems of fragile lenses, inconvenient adjustment, low clamping precision, etc., and achieve the effect of strong protection and guaranteed clamping precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

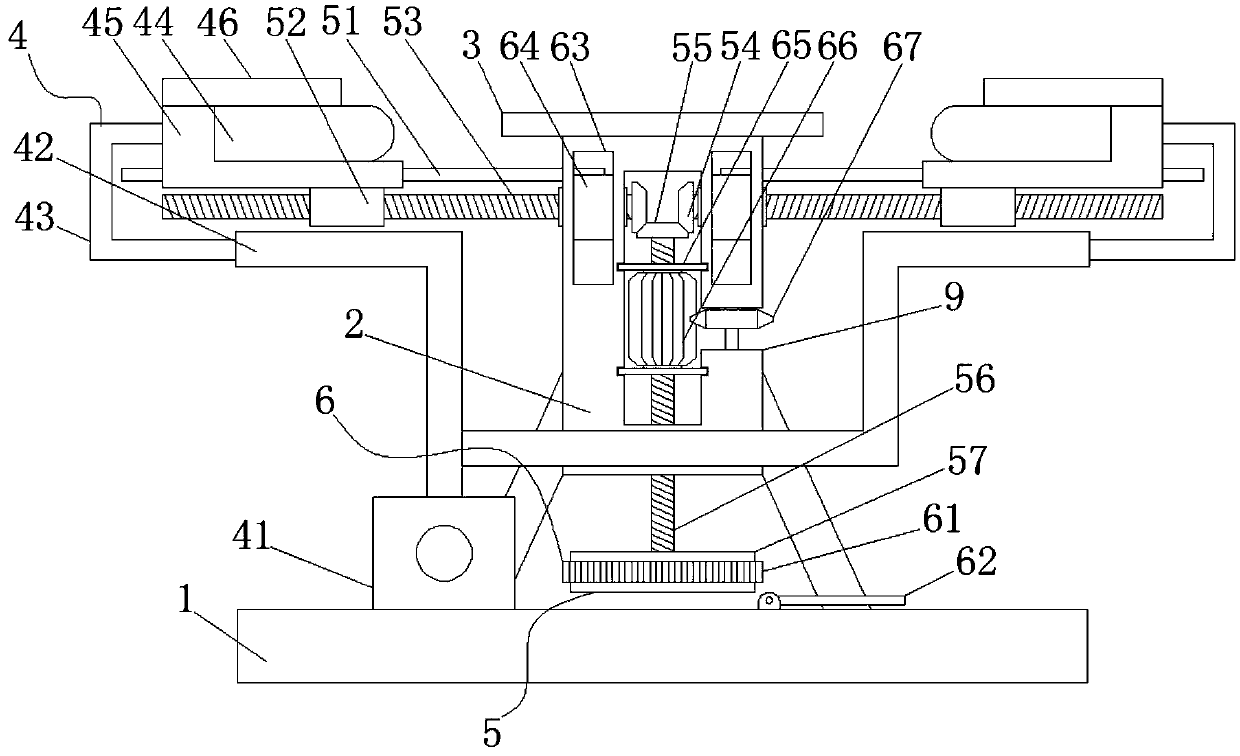

[0038] Such as figure 1As shown, a high-precision intelligent feeding tool provided in Embodiment 1 includes a base plate 1 and a support column 2 fixedly installed on the upper end surface of the base plate 1. Specifically, four support beams are fixedly installed around the outer surface of the support column 2 , and the bottom end of the support beam is fixedly installed on the upper end surface of the base plate 1 to support the support column 2. The upper end surface of the support column 2 is fixedly installed with a support platform 3, and the right side of the support platform 3 is provided with a window 9. include:

[0039] Four clamping mechanisms 4 are symmetrically distributed around the support column 2 and are used to clamp materials from four directions; the clamping mechanism 4 includes an air pump 41, a sleeve 42, an air intake pipe 43, and an arc-shaped air bag 44. The lower backing plate 45 and the upper backing plate 46, the air pump 41 is fixedly installe...

Embodiment 2

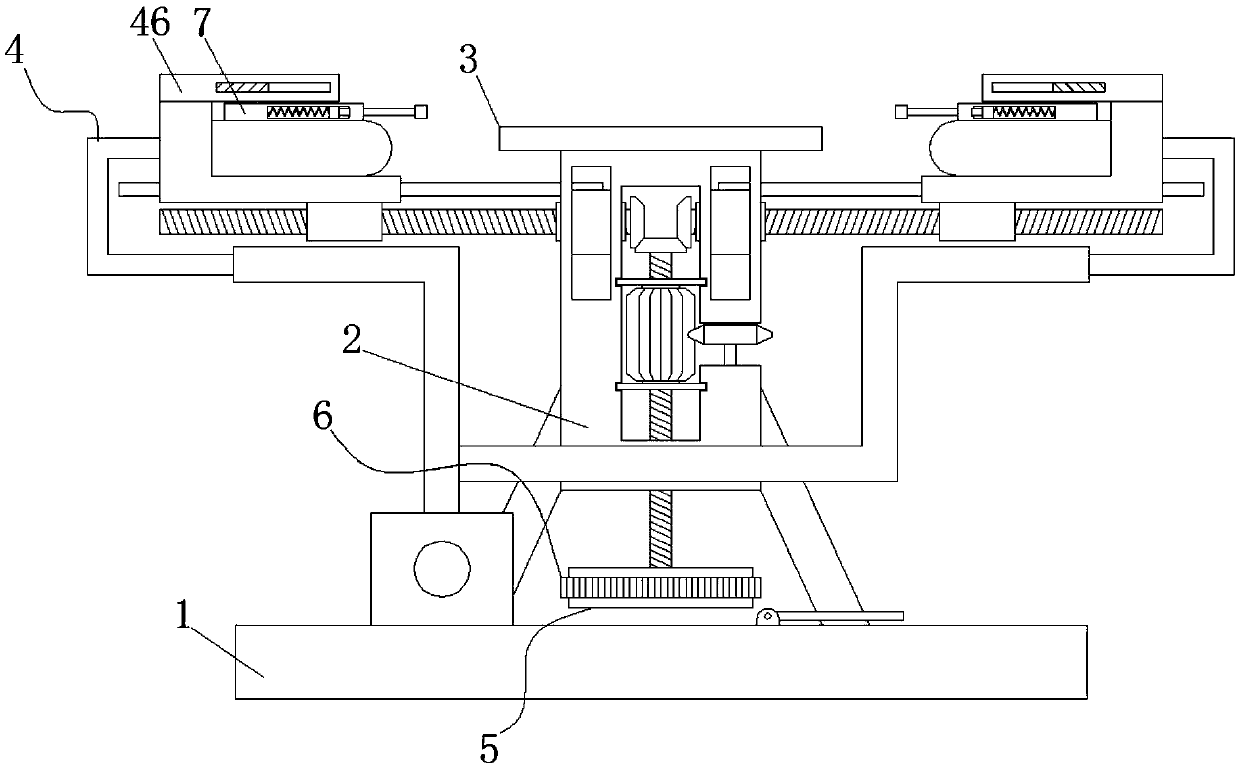

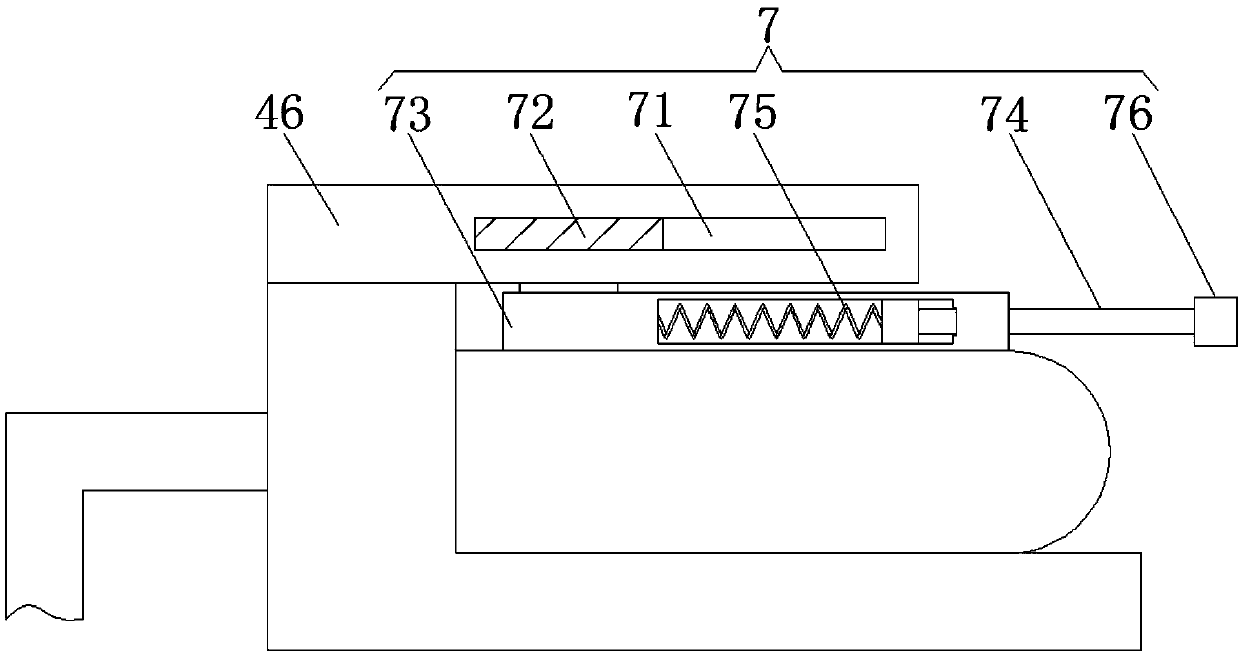

[0047] Such as Figure 2-3 As shown, the difference between this embodiment and the first embodiment is that: it also includes a pre-positioning component 7, which is arranged inside the clamping mechanism 4;

[0048] Pre-positioning assembly 7 comprises transverse chute 71, slide plate 72, baffle plate 73, telescoping rod 74, spring 75 and top block 76, and transverse chute 71 is offered at the bottom of upper backing plate 46, and slide plate 72 is arranged on the bottom of transverse chute 71. Inner cavity, the lower end surface of the slide plate 72 extends to the bottom of the upper backing plate 46, and the slide plate 72 can slide in the inner cavity of the transverse chute 71, and one end of the top of the baffle plate 73 is fixedly installed on the lower end surface of the slide plate 72, and the baffle plate 73 The lower end surface of the arc-shaped airbag 44 is fixedly connected to the upper end surface of the arc-shaped airbag 44. Specifically, during the expansio...

Embodiment 3

[0051] Such as Figure 4 As shown, the difference between this embodiment and the above-mentioned embodiments is that it also includes a storage slot 8, and a stopper is provided near one end of the support table 3, and the size of the storage slot 8 is larger than the size of the top block 76, when the clamping mechanism 4 After moving a certain distance, the airbag contacts the optical lens, and the top block 76 will enter the storage groove 8, and the contact part between the arc-shaped airbag 44 and the optical lens will expand upwards, and the expanded part will extend to between the top block 76 and the optical lens. Block 76 does not come into contact with the optical lens, further enhancing the effect of flexible clamping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com