Movable spanner

An adjustable wrench and wrench technology, applied in the field of connection, disassembly or clamping tools and fastening, can solve the problems of increasing material, affecting the accuracy of clamping gap, shaking of movable jaws, etc., to achieve reasonable stress conditions and extended use. The effect of high life and high clamping accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

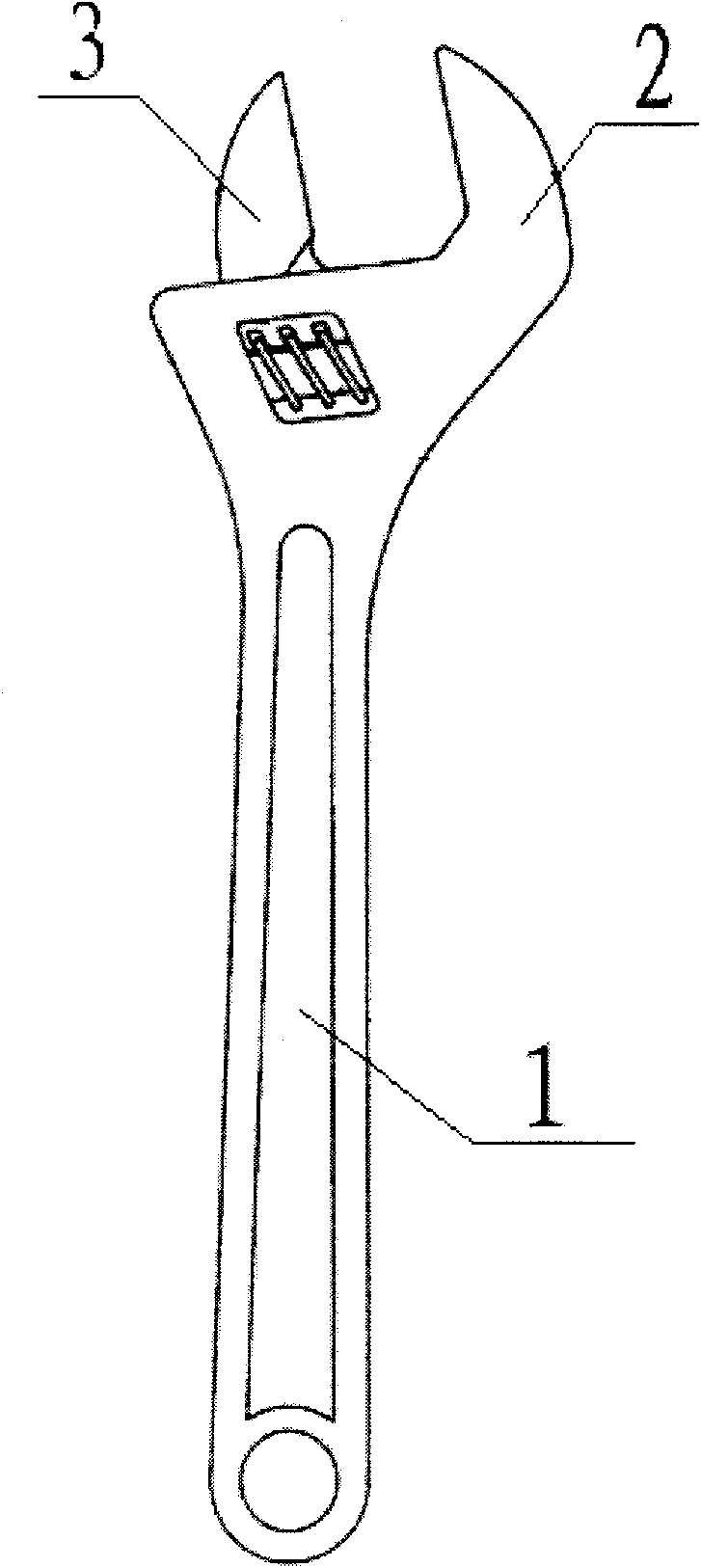

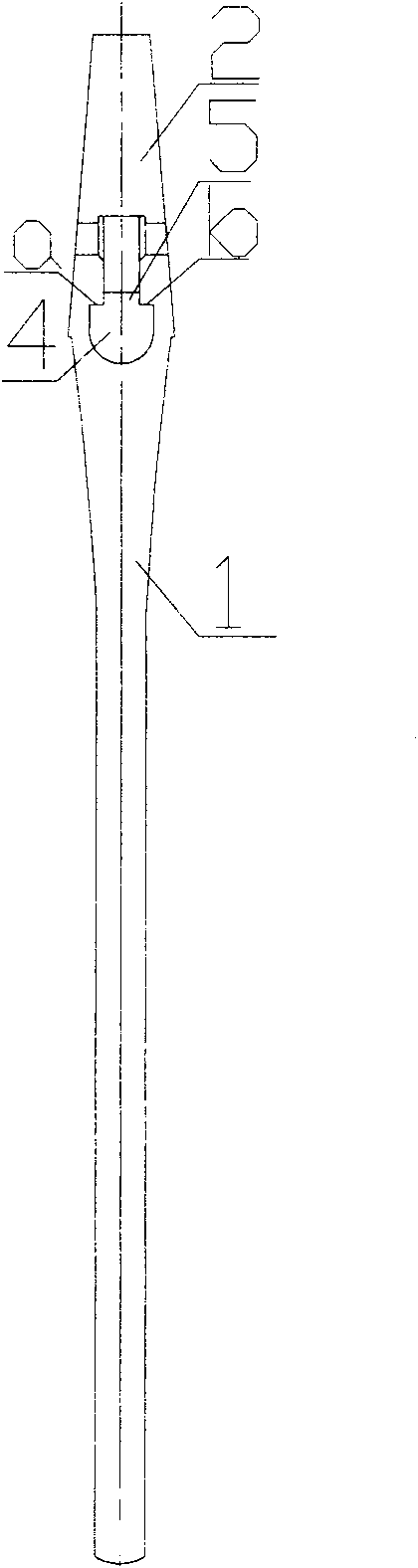

[0018] As shown in the figure, the movable wrench includes a wrench body 1, a fixed jaw 2 and a movable jaw 3. The front end of the wrench body 1 is provided with a fixed jaw 2, and the fixed jaw 2 is provided with a sliding groove 4 adjacent to it. The slide rail 5, the moving column 6 integrated with it is arranged axially under the movable jaw 3, and the moving column 6 is embedded in the sliding groove 4 and the slide rail 5. The inner surfaces a and b of the slide groove 4 adjacent to the slide rail 5 are horizontal, and the corresponding outer surfaces c and d of the moving column 6 are also horizontal. When the wrench is working, the force acting on the inner surface of the sliding groove 4 is the force perpendicular to the a surface and the b surface, that is, the vertical force. This force has no component force in the horizontal direction, so the fixed jaw 2 and the movable jaw 3 can be eliminated. The gap between the adjustable wrench will not cause the movable jaw ...

Embodiment 2

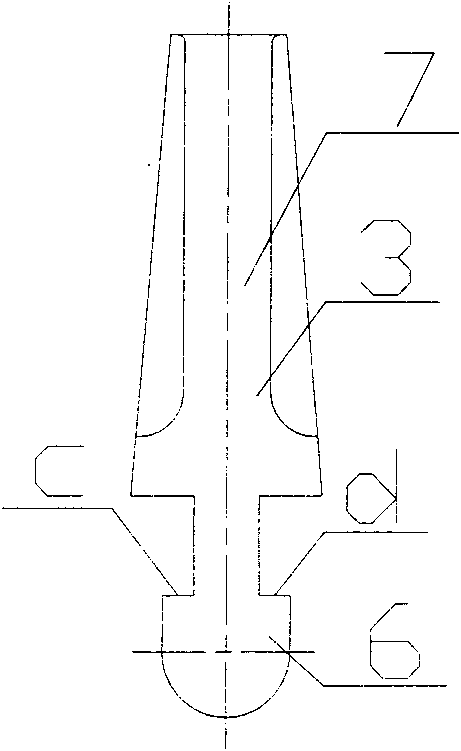

[0022] Such as Figure 4 and Figure 5 As shown, the inner surfaces a and b of the sliding groove 4 adjacent to the slide rail 5 are an inclined plane, and the cross-sectional shape of the plane is shown in the figure, which is up high and down low. The c-plane and d-surface of the corresponding outer surface of the moving column 6 are also inclined planes, and their cross-sectional shapes are correspondingly up-up and down-down. When the wrench is working, the force acting on the inner surface of the sliding groove 4 is shown in the figure, and the component force of the force in the horizontal direction points to the groove, so it will not generate an outward thrust on the sliding groove 4, eliminating the need for fixing clamps. The gap between mouth 2 and movable jaw 3.

[0023] Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com