A wheel milling machine rocker mechanism capable of lifting and turning

The technology of a rocker arm mechanism and a milling machine is applied in the field of construction machinery, which can solve the problems of complex force on the oil cylinder, unfavorable service life and performance, and achieve the effect of improving the steering performance, the force situation is reasonable, and the steering performance is guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing, the present invention is described in further detail:

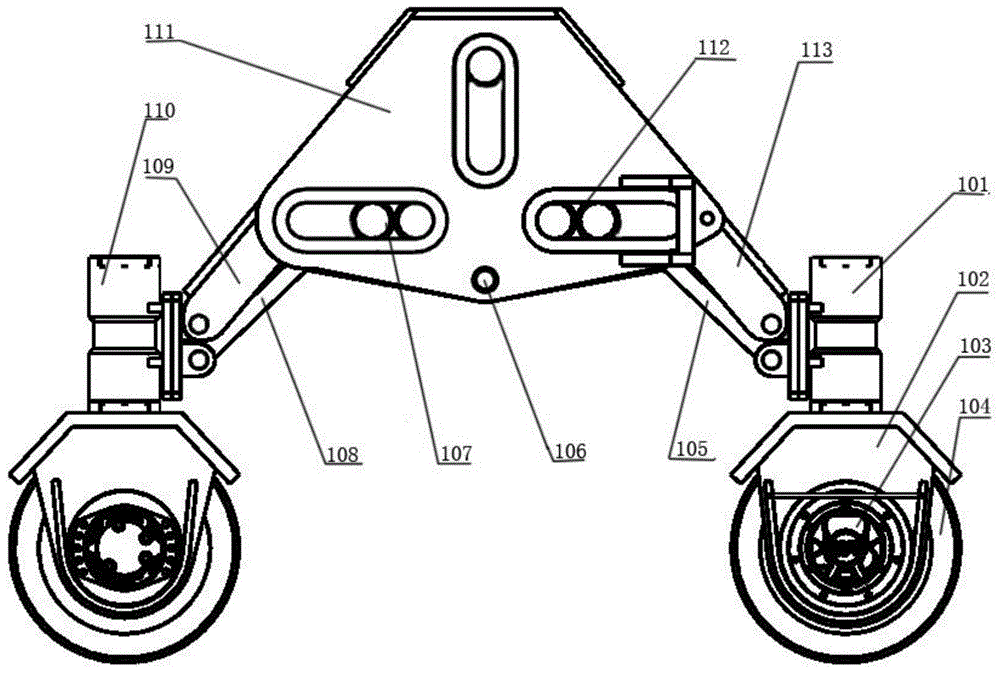

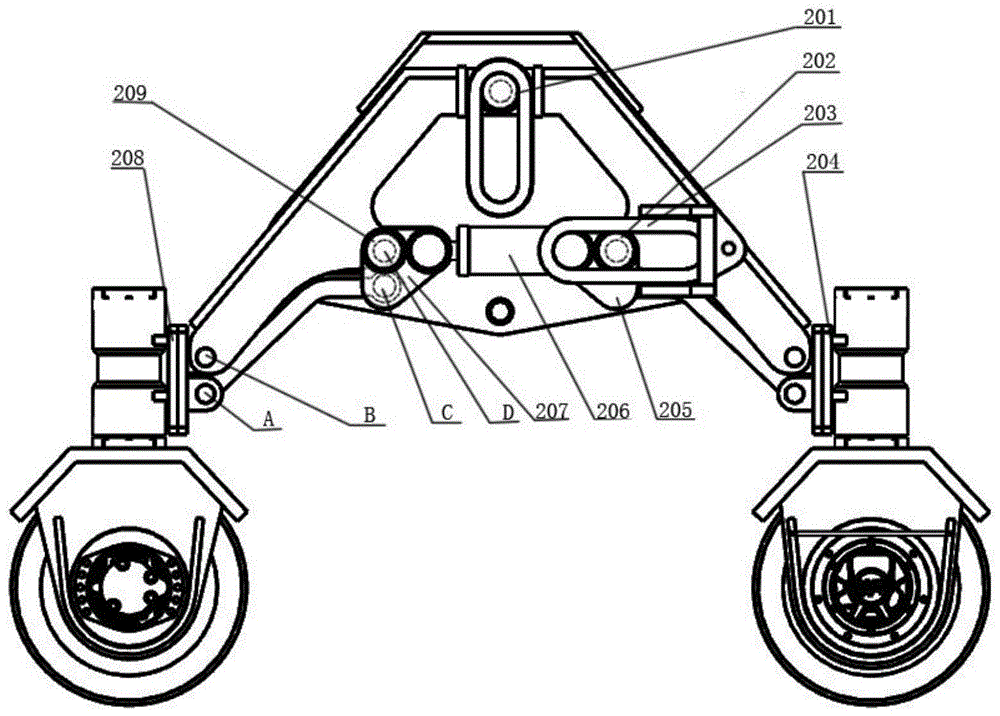

[0040] Such as figure 1As shown, the present invention is a wheel milling machine rocker mechanism that can realize lifting and turning, which is composed of a rocker arm frame 111, a front rocker arm 109, a rear rocker arm 113, a rocker four-bar linkage mechanism (the front wheel is an example) , including front rocker arm 109, front steering oil cylinder fixed flange 208, front rocker arm lower arm 108 and front angle plate 207) and front steering oil cylinder 110 and rear steering oil cylinder 101 etc. composition. The up and down movement of the milling machine body relative to the ground is realized through the telescopic movement of the linear hydraulic cylinder 206, thereby realizing the milling function of the milling machine. The steering cylinder can be installed on the front and rear wheels respectively (the figure shows that both the front and rear wheels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com