Slide block structure of wheel rim slag scraper

A technology of slag scraper and slider, which is applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of slider damage to molds, etc., and achieve the effect of reasonable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

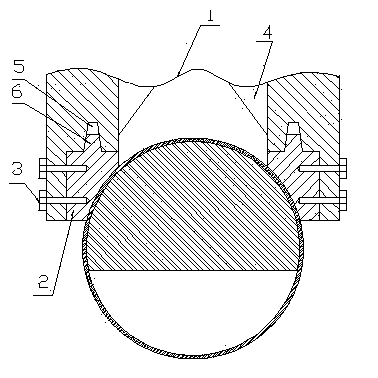

[0010] In the figure, the structure of the slider of the wheel rim slag scraper includes a slider 1, a mold body 2, a positioning bolt 3, a "herringbone"-shaped rib 4, a tapered hole 5, a tapered platform 6, and a right-angle seam 7, A "herringbone"-shaped reinforcing rib 4 is symmetrically arranged on the upper part of the middle opening of the slider 1, and a right-angle stop 7 is symmetrically formed on the openings on both sides of the lower part of the slider 1, and on the horizontal side of the right-angle stop 7 A tapered hole 5 is formed, and the mold body 2 is fixed on the right-angle seam of the slider 1 through a positioning bolt 3, and a conical platform 6 is formed on the upper plane of the mold body 2, and the conical platform 6 is engaged in the Inside the tapered hole 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com