Blanking device

A technology of blanking device and driving device, which is applied in metal processing and other directions, can solve the problems of manual operation danger, high labor intensity of workers, low work efficiency, etc., and achieve the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

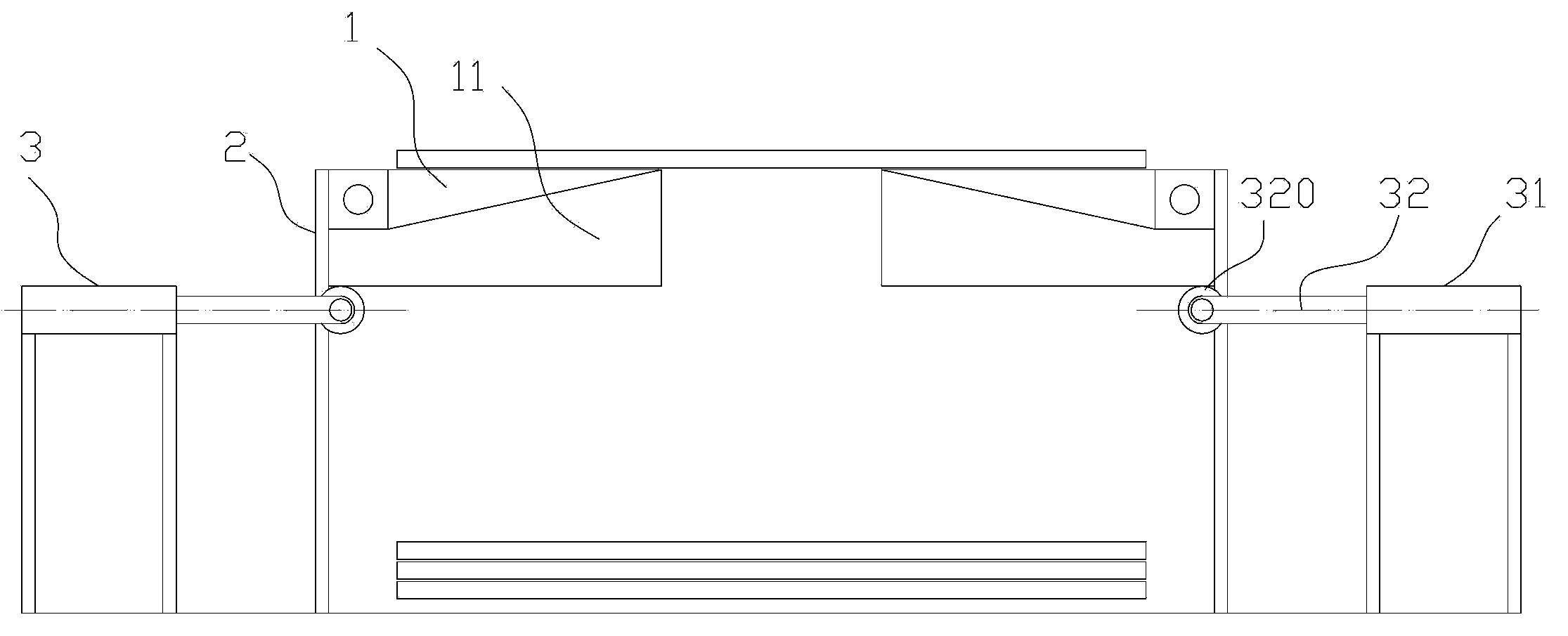

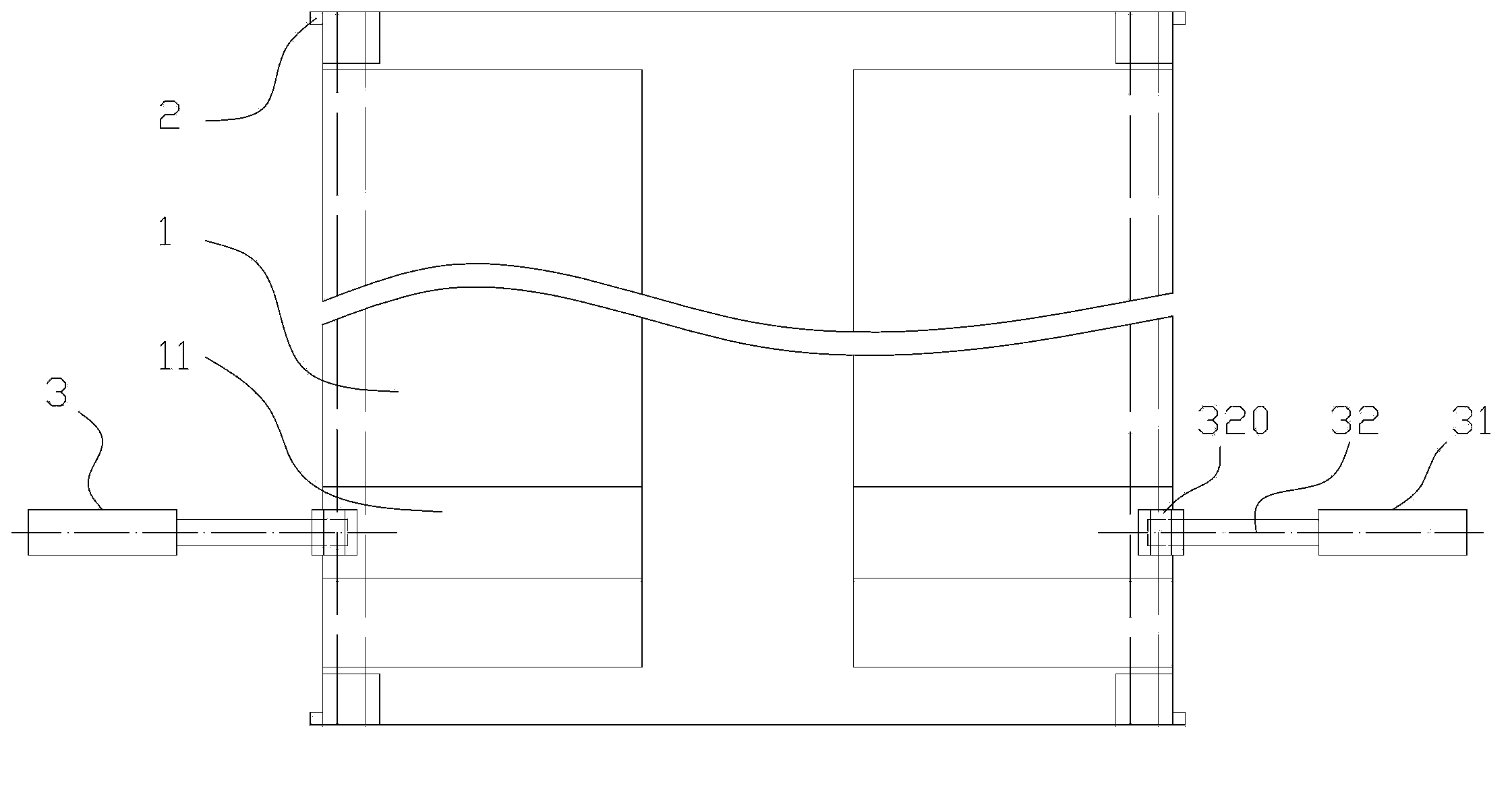

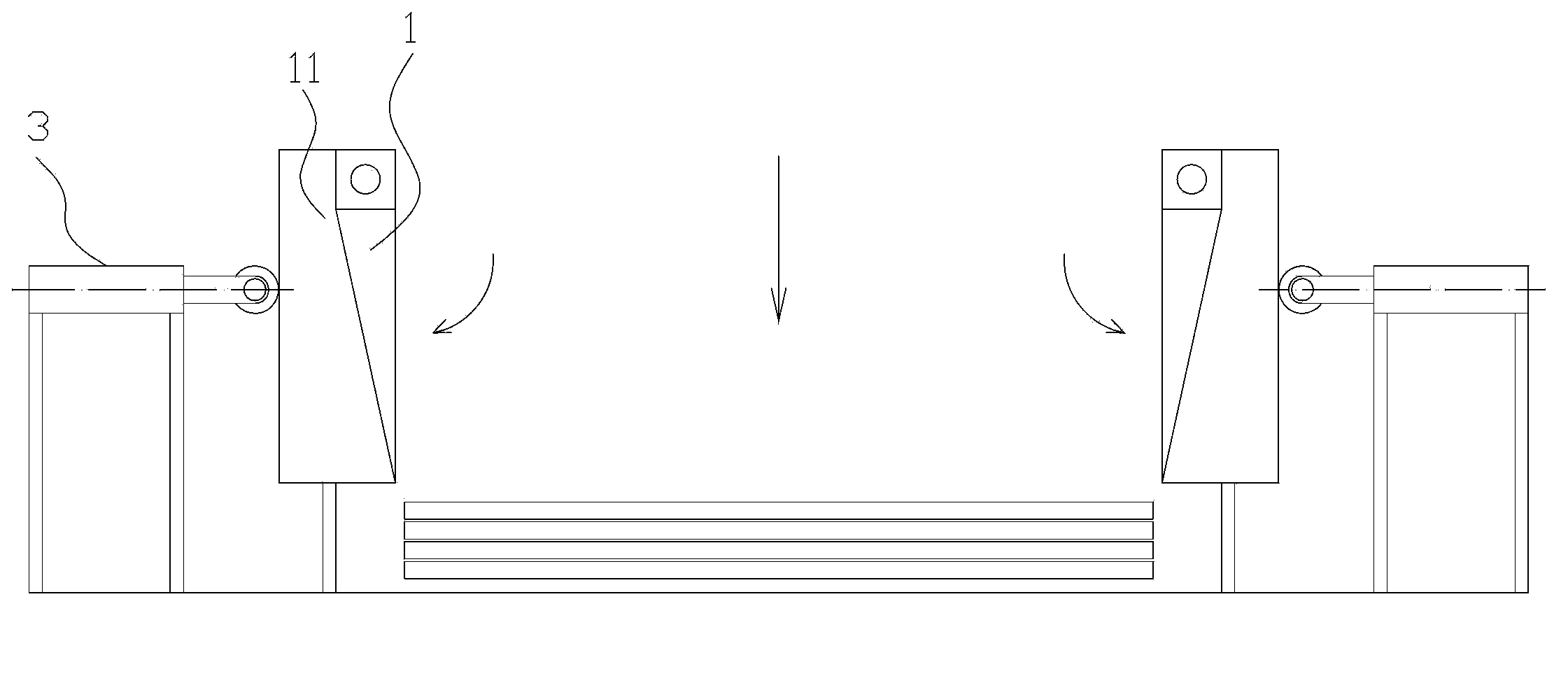

[0015] The present invention as Figure 1-3 As shown, it includes a pair of support plates 1 with a triangular cross section and a frame-shaped frame 2, and a pair of support plates 1 are symmetrically and flexibly connected to the top of the frame 2,

[0016] The bottom surface of the supporting plate 1 is provided with a square block 11;

[0017] The blanking device also includes a pair of driving devices 3 and a pair of control switches, the driving device 3 includes a driving cylinder 31 and a driving rod 32, and the driving rod 32 is horizontally arranged at a corresponding position below the square block 11, The driving cylinder 31 is sleeved on the driving rod 32 and is fixedly connected with the frame 2; when the supporting plate 1 needs to be closed, the driving cylinder 31 is used to push out the driving rod 32 to effectively lift the square. block 11, and then the support plate 1 is jacked up by the square block 11, so that the support plate 1 is closed; Plate 1 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com