Method for conducting laser shock micro-shaping on titanium alloy artificial acetabular cup

A technology of hip joint socket and laser shock, applied in the direction of hip joint, acetabular socket, joint implant, etc., can solve the problems of reducing surface friction coefficient, harsh processing conditions, easy cracking, etc., to improve wear resistance, The effect of increasing the probability of occurrence and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

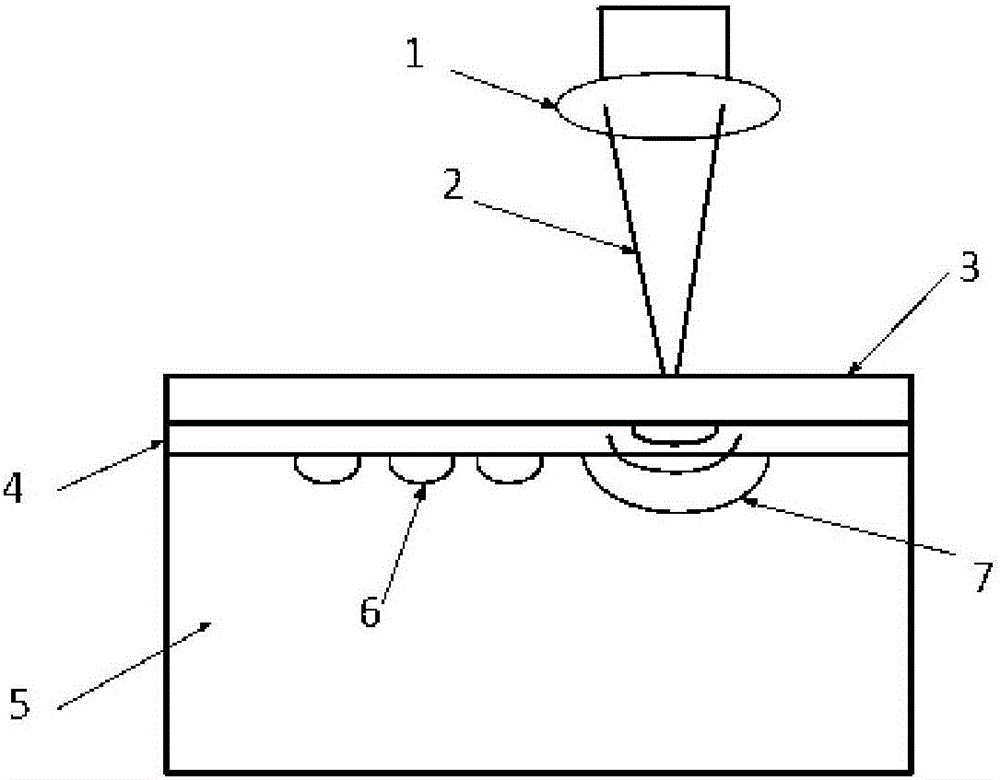

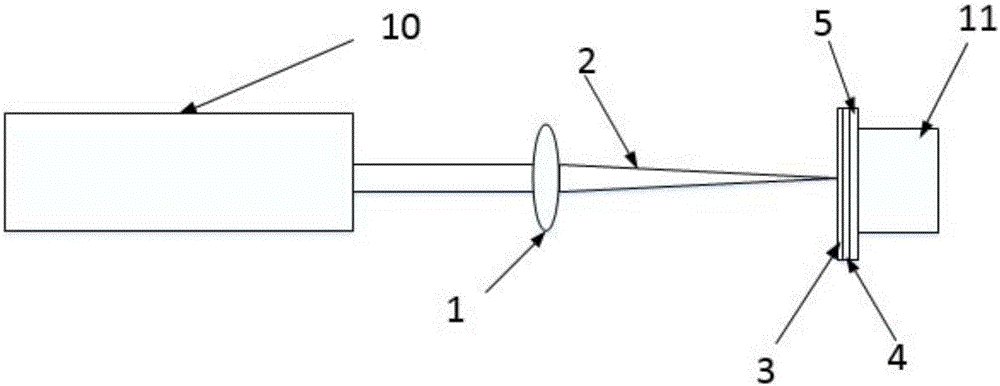

[0024] Such as figure 1 As shown, the principle of the present invention: a target 5 is installed on the workbench 11, a laser 10 is arranged above the target 5, and the laser beam 2 emitted by the laser 10 is irradiated on the target 5 through a focusing lens 1, and the target 5 An energy absorbing layer 4 and a constraining layer 3 are provided in sequence on the upper surface, and the laser beam forms micro pits 6 on the surface of the target 5 through shock waves 7 .

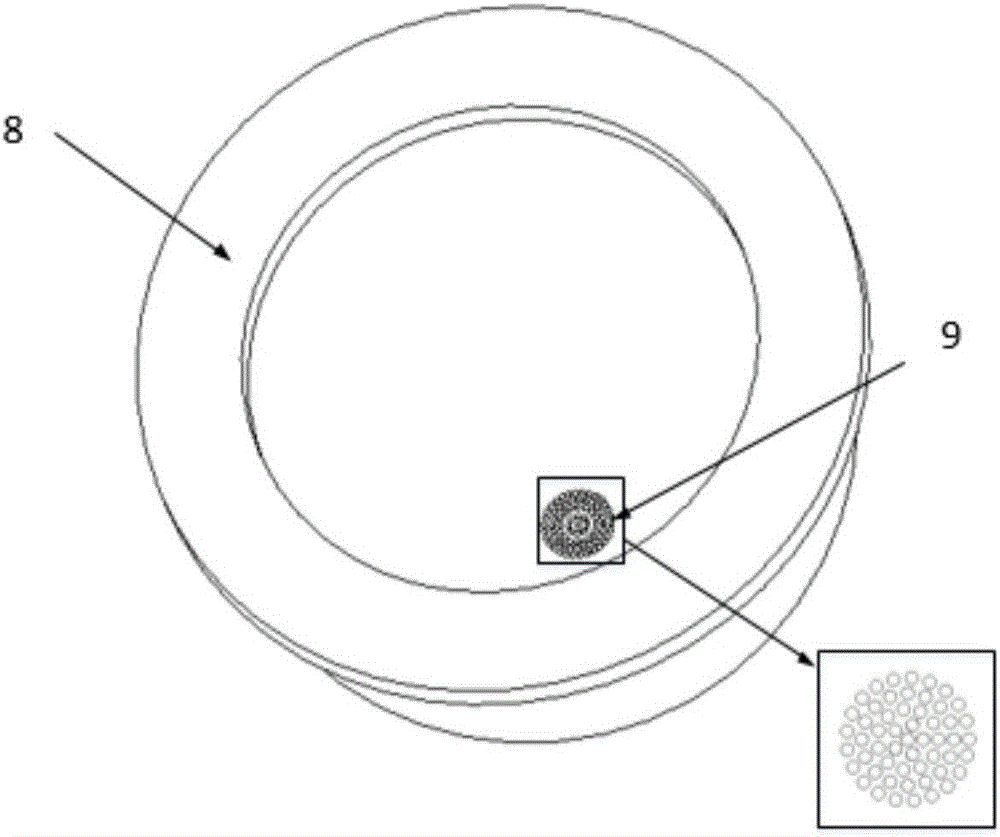

[0025] Such as image 3 As shown, the processing device of the present invention includes a laser 10 , a focusing lens 1 and a worktable 11 , and the laser beam 2 generated by the laser 10 irradiates the wearable area 9 of the hip joint cup 8 on the worktable 11 through the focusing lens 1 .

[0026] A method for laser shock micro-modeling titanium alloy artificial hip joint cup, comprising the fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com