Screw compressor

A technology for screw compressors and shells, which is applied in the direction of rotary piston machinery, mechanical equipment, machines/engines, etc., which can solve problems such as inability to supply oil, increased contact pressure, and mutual friction between metals, so as to reduce forced wear and prolong life , to avoid the effect of dry friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0025] In the figures described below, the parts having the same structures as those shown in the preceding figures are denoted by the same symbols for description.

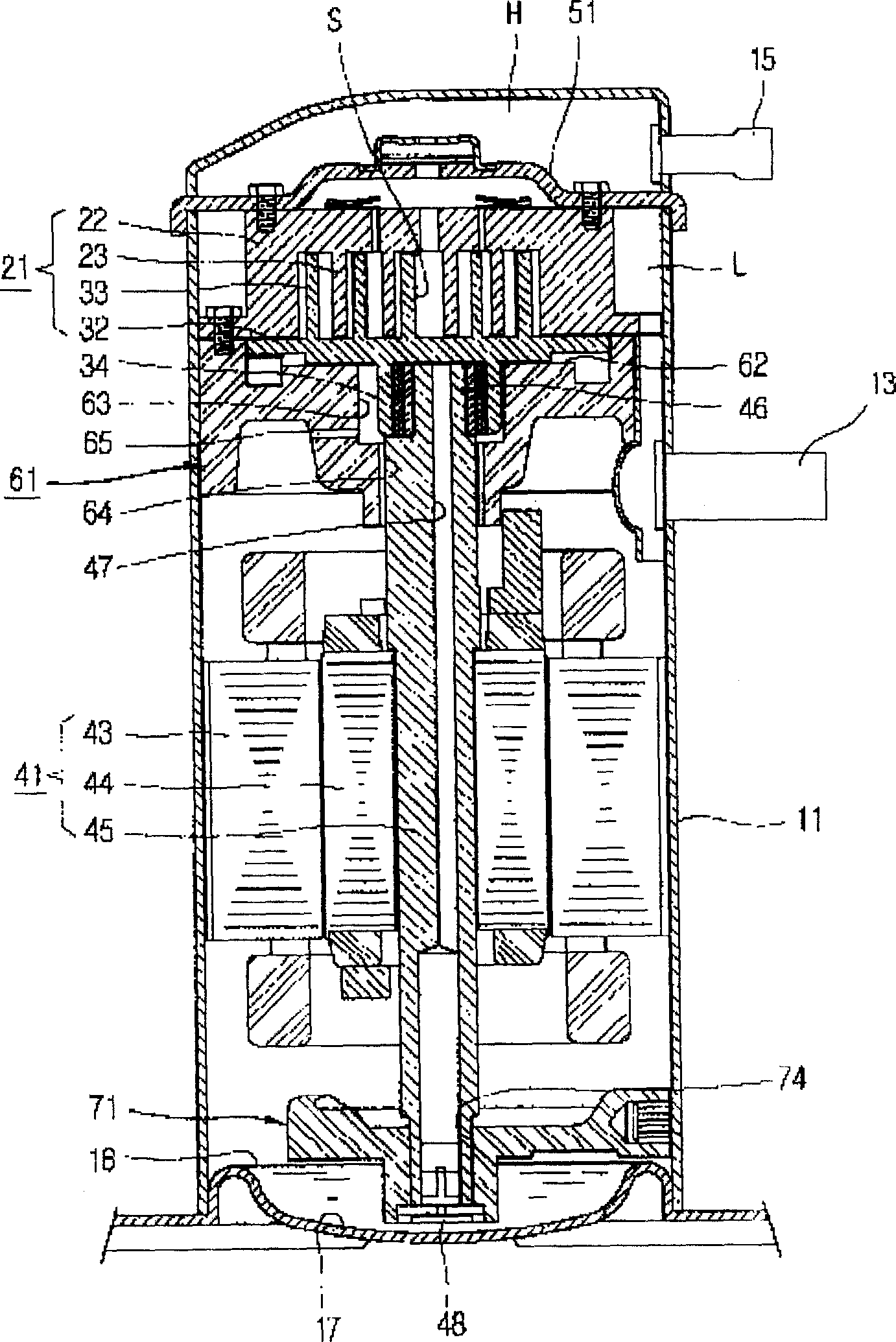

[0026] As shown in the figure, the screw compressor consists of the following parts:

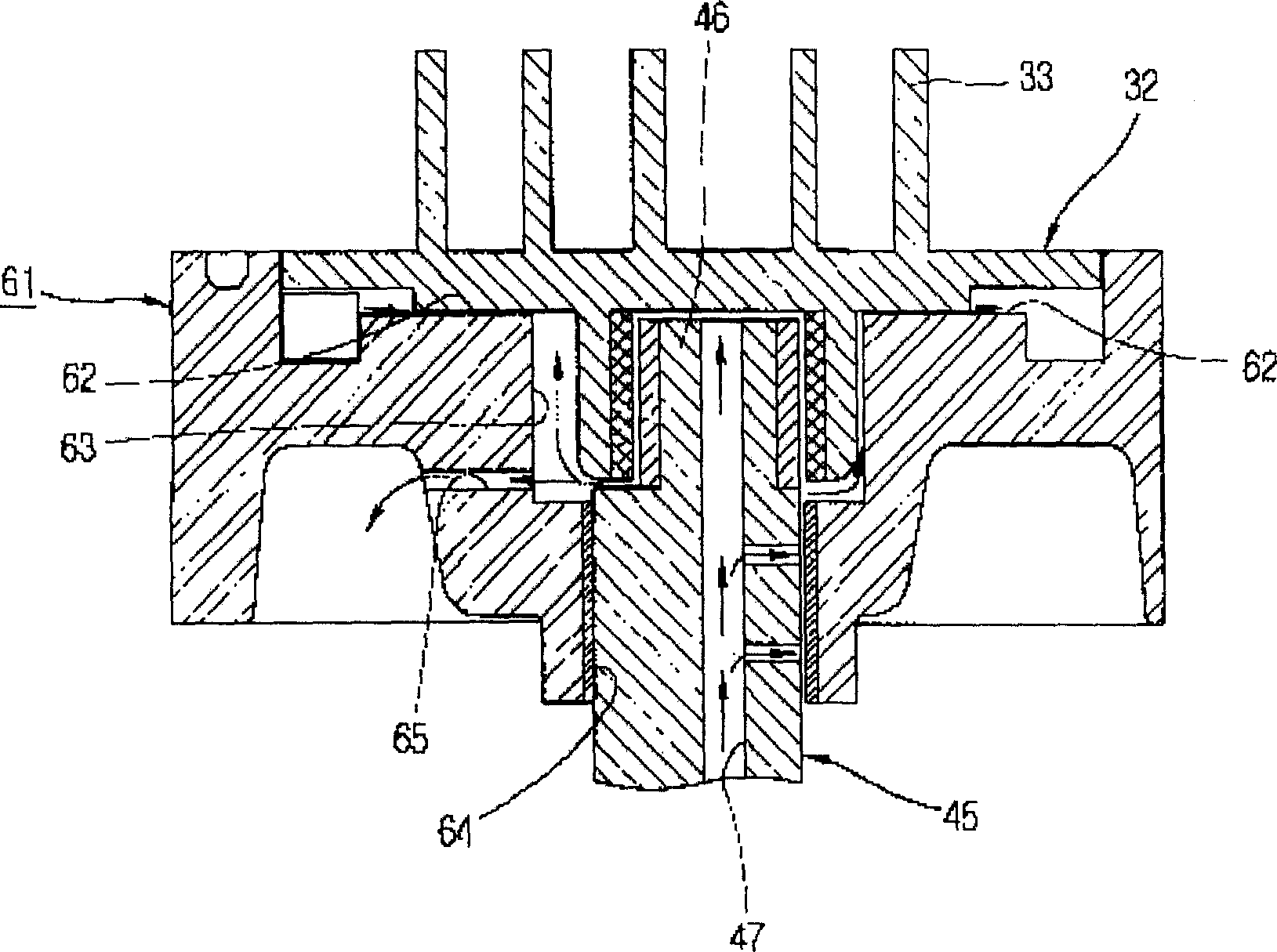

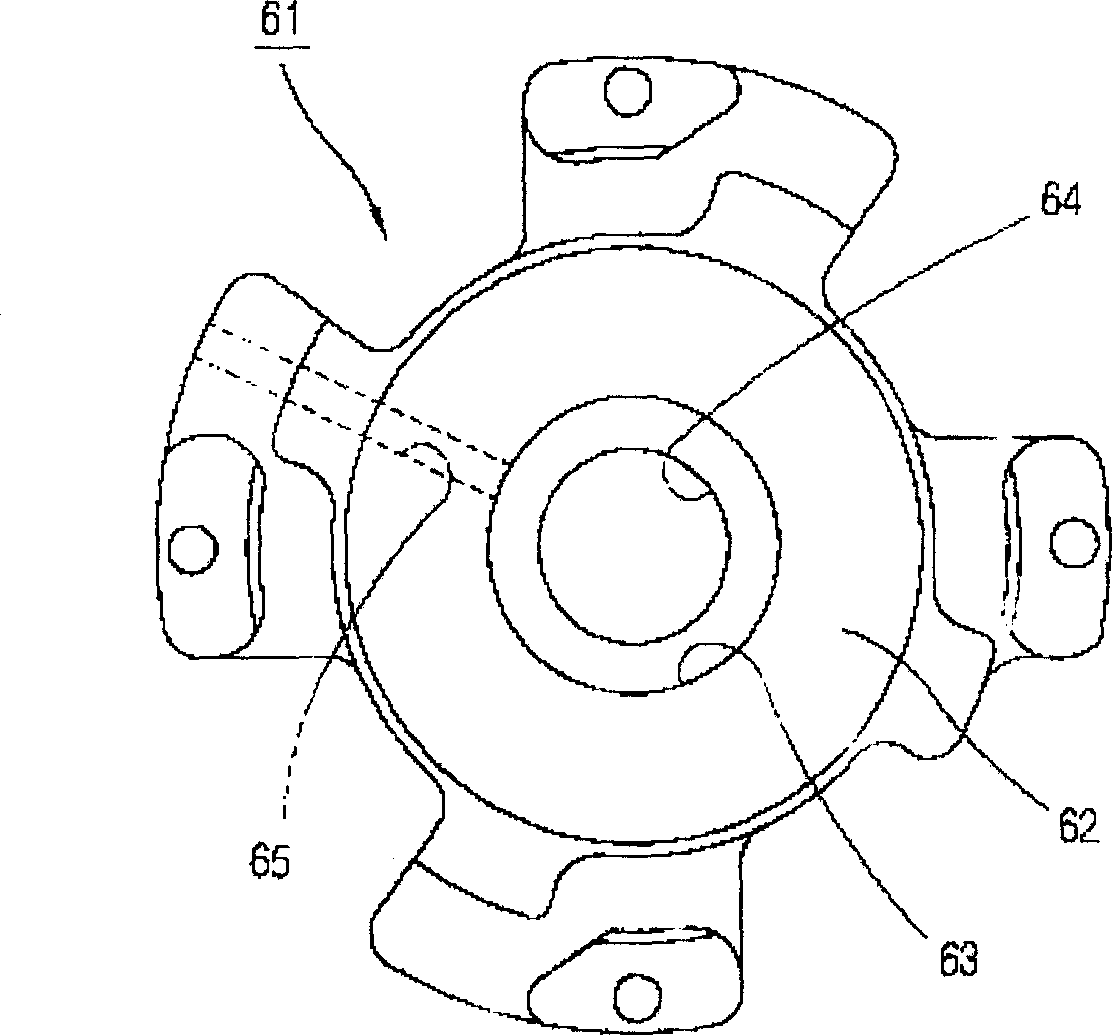

[0027] The present invention is a kind of screw type compressor, and its structure comprises the casing 11 that its inside forms sealed space; The refrigerant compression space has an involute shape rotating wing 33, and the movable scroll 32 that rotates with the fixed scroll 22; the main frame 61 that supports the movable scroll 32 to perform eccentric movement and contacts with its bottom surface forms a bearing surface 62, at least On one of the bottom surface of the orbiting scroll 32 and the insertion bearing surface 62 , there is an oil storage portion 81 that is recessed along the axial direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com