Method and apparatus for treating a subterranean formation

A kind of equipment and formation technology, which is applied in the field of completing wellbore processing, and can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

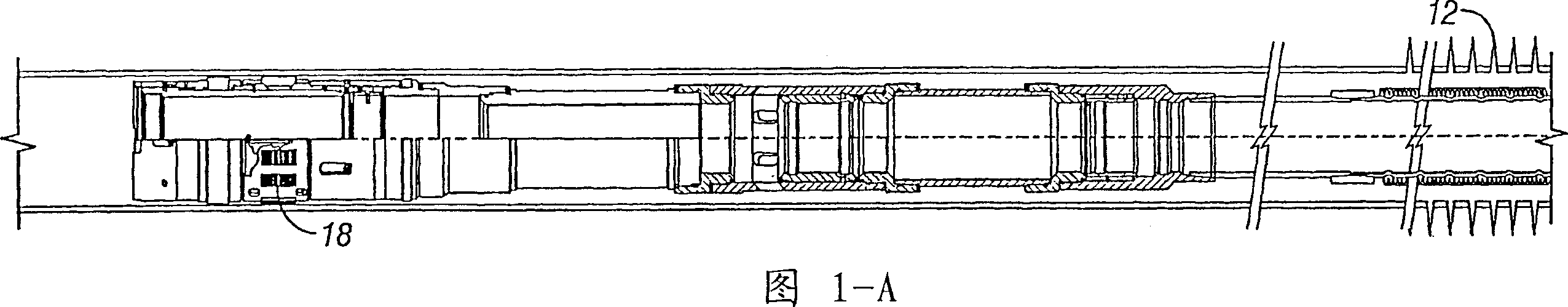

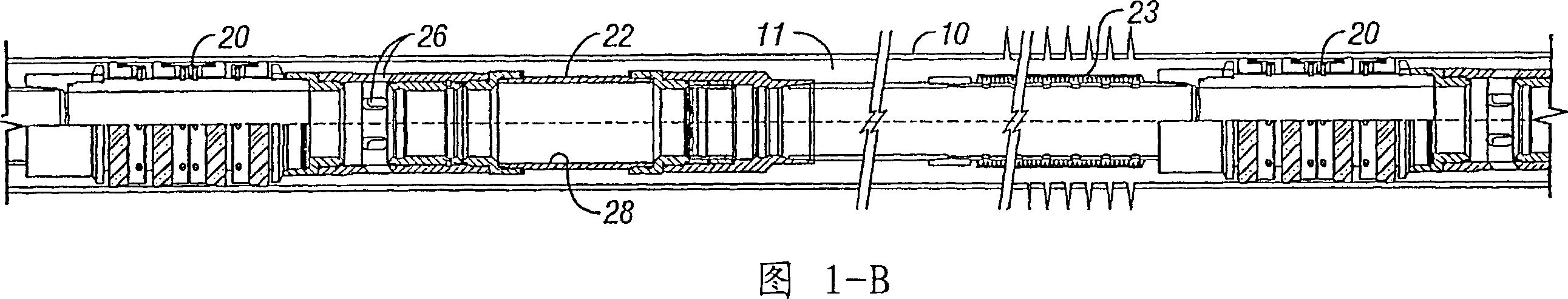

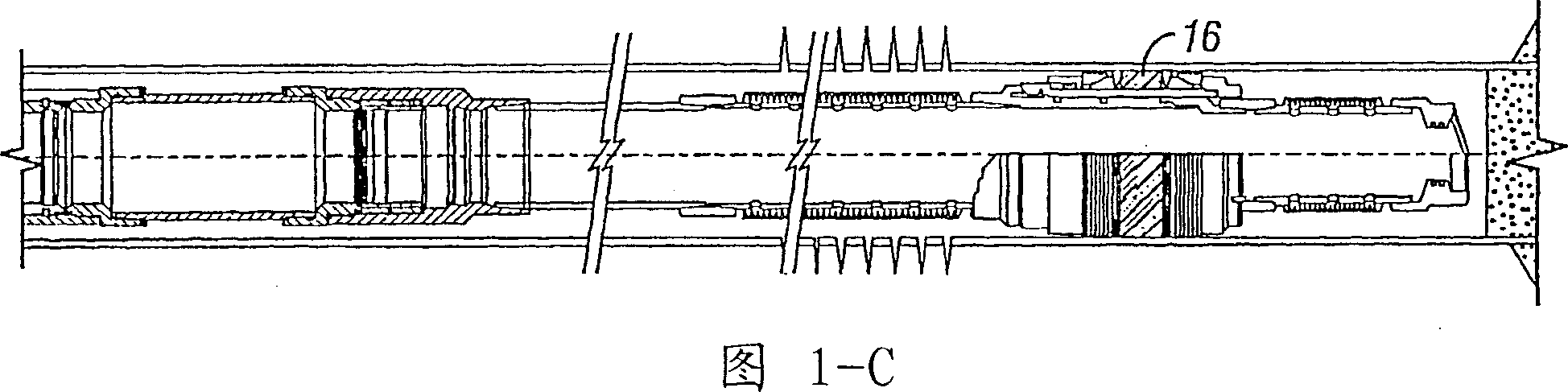

[0052] Referring now to the drawings, and first to Figures 1-A through 1-C, the casing is generally indicated at 10 and is perforated at a plurality of intervals, indicated at 12, to complete a well for producing petroleum products from a plurality of subterranean regions. While wellbores are shown as being substantially evenly spaced, it should be understood that casing boreholes are generally positioned in a non-uniformly spaced relationship, with spacing depending on the location or depth and width of the various subterranean zones of interest.

[0053] As shown, a service / completion liner, shown generally at 14, is positioned within perforated casing 10 and is adapted to latch into a reservoir packer 16 that forms a seal within the casing. The liner is designed for use with work tools that have a hydraulically actuated dump valve. Tank packers isolate the pressure conditions in the lowest perforated area from the multiple perforated areas of the casing. The service / comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com