Numerical control machining method for combined matched drilling of taper holes of high-pressure turbine rotor

A technology of high-pressure turbine and processing method, which is applied in the field of numerical control processing, can solve the problem of low precision of the taper hole of the combination drill, and achieve the effect of ensuring the assembly requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

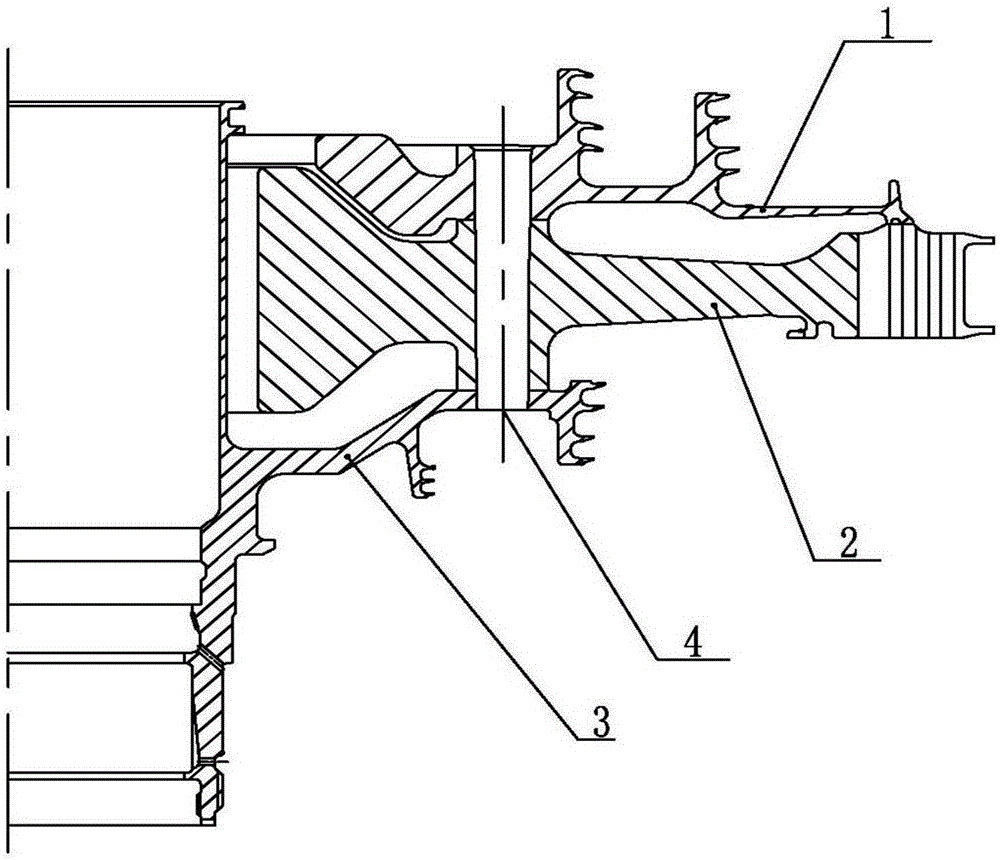

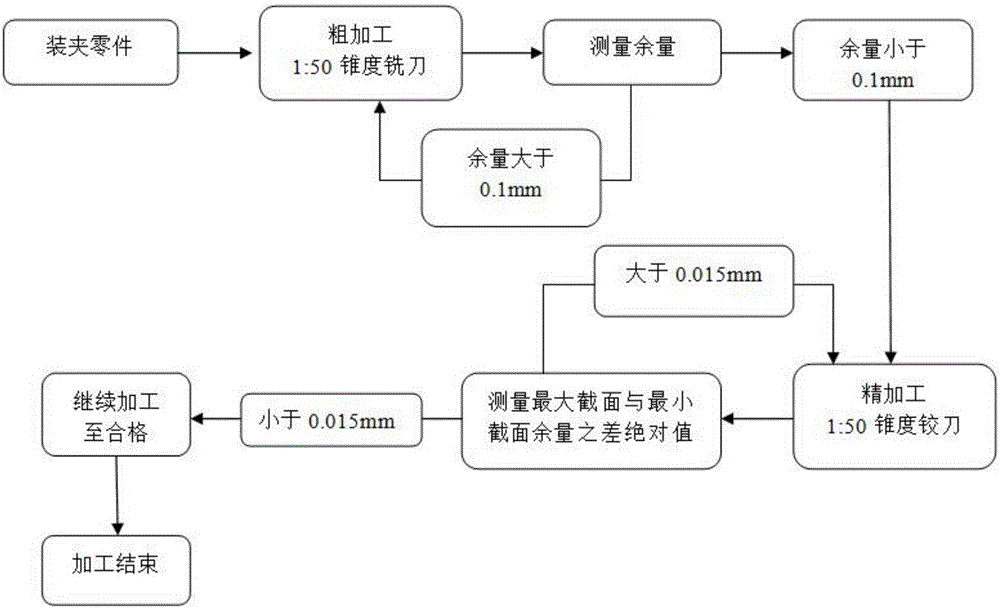

[0022] Such as figure 1 As shown, the high-pressure turbine rotor of the engine is composed of three parts, of which part 1 is the sealing grate tooth disc, part 2 is the high-pressure turbine disc, and part 3 is the rear journal of the high-pressure turbine. The materials of the three parts are superalloys of different grades ; 4 is the taper hole after combination drilling, the taper of the hole is 1:50, and the depth is 61mm. Part 1, part 2 and part 3 are connected and centered by 8 taper holes 4 during the assembly process. figure 1 It can be seen that when the reamer is processed from top to bottom, the front part of the tool has the largest stroke and the most serious wear. In order to solve this problem, it is necessary to track the degree of wear of the tool during machining. The present invention establishes a feedback mechanism , which controls the processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com