Air sealing construct design for electric main shaft of oil grease mill

A technology of structural design and electric spindle, which is applied in the direction of engine sealing, electrical components, electromechanical devices, etc., can solve the problem of increased maintenance and use costs of electric spindles, bearings that do not reach the designed service life, and unsuitability for high-speed grinding of electric spindles, etc. problems, to achieve the effect of long service life, small sealing power consumption, and simple air-tight structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

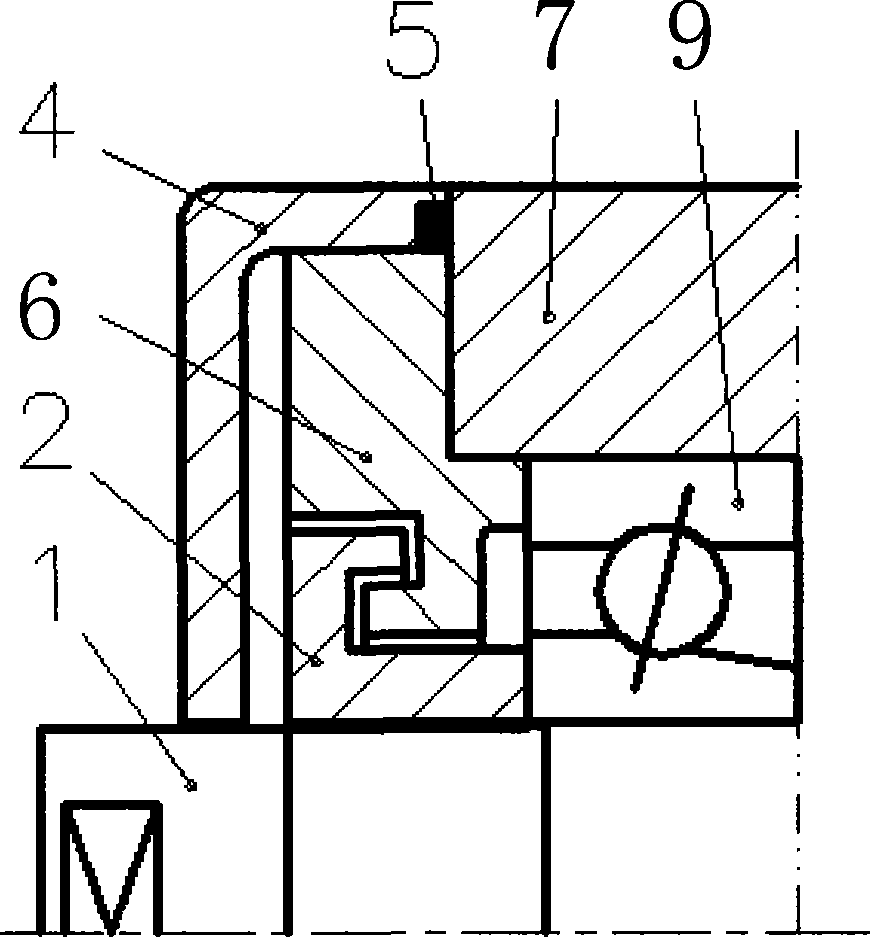

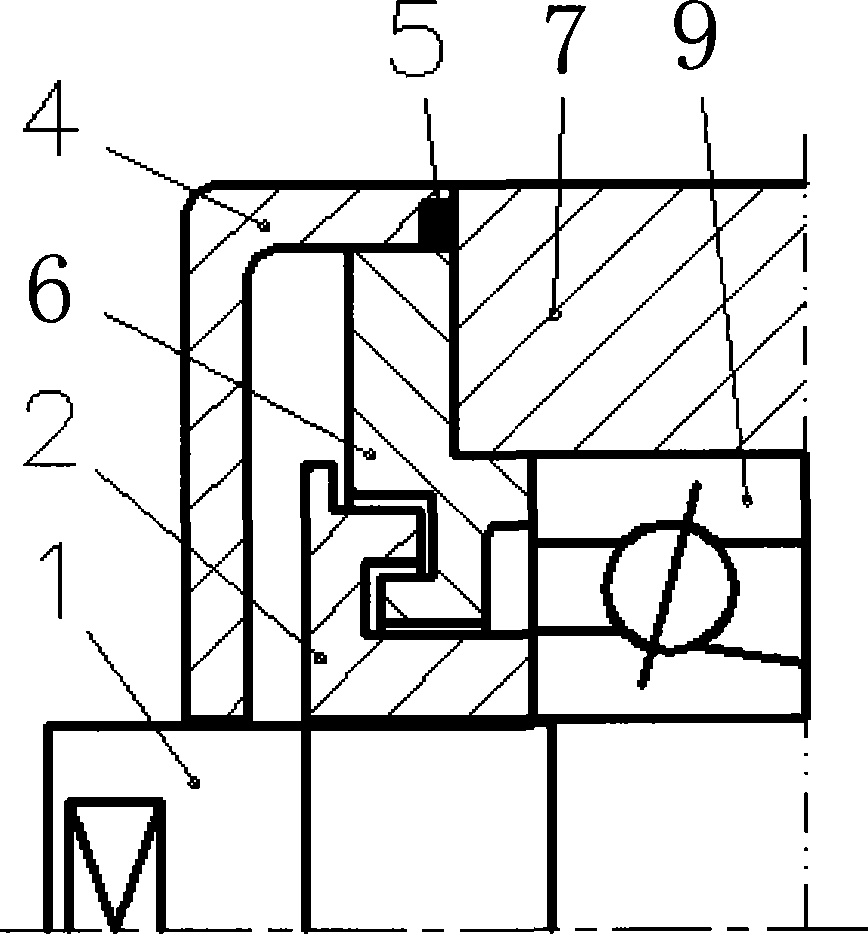

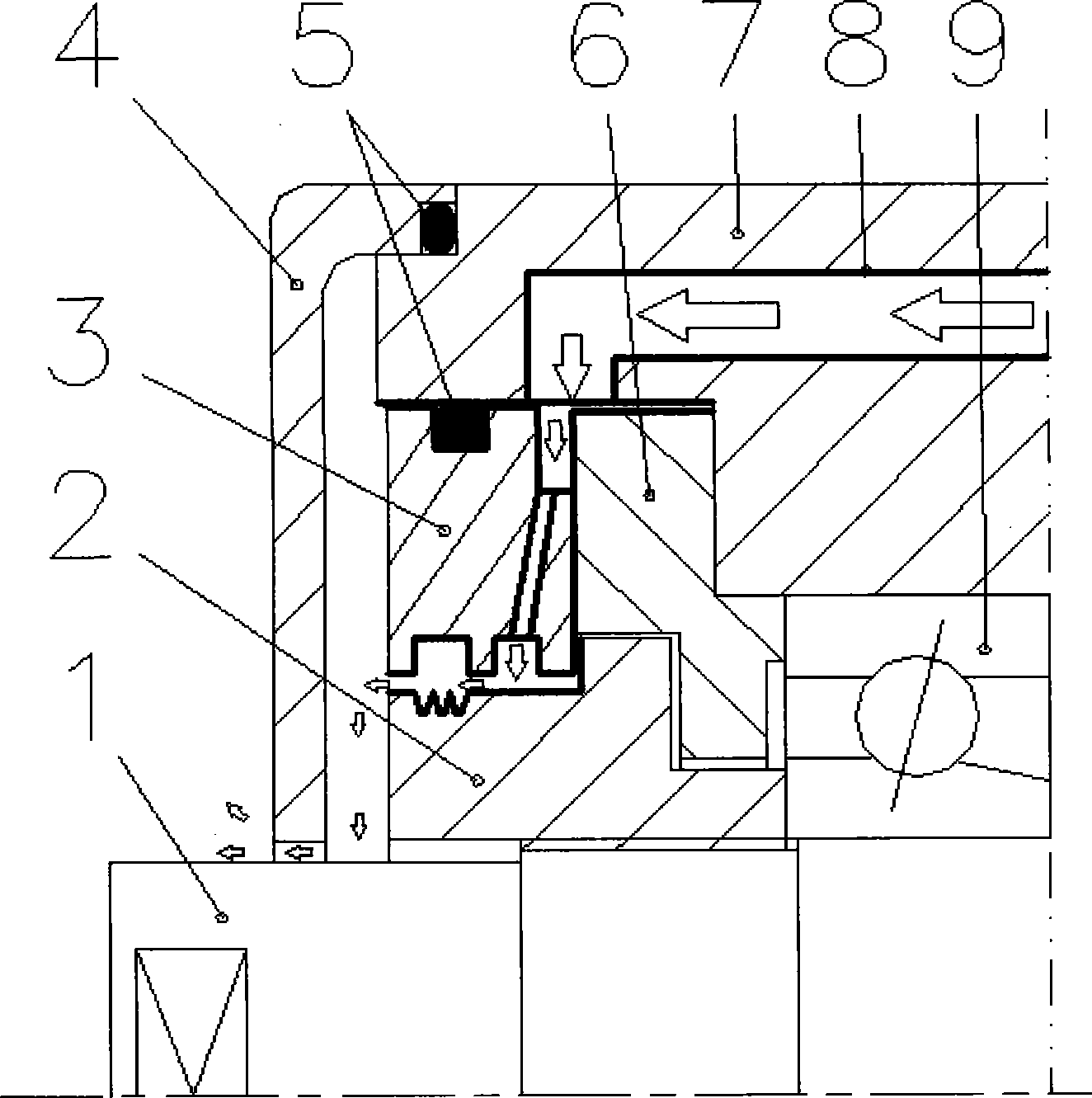

[0017] combine image 3 , the design of the air seal structure of the electric spindle for grease grinding of the present invention is that the clean air with a certain pressure enters the baffle plate (3) and the front small cover (6) through the air channel (8) provided on the front bearing seat (7). ) in the annular cavity, and then reach the annular groove of the baffle (3) through the radial oblique holes evenly distributed on the circumference of the baffle (3) annular cavity, the inner circle of the baffle (3) and the front nut (2) There is a gap in the outer circle, and the front nut (2) is designed with a serrated groove, which corresponds to another annular groove in the inner circle of the baffle (3). With the high-speed rotation of the shaft (1), the pressure The air forms a pressure air sealing ring in the gap and the two grooves, preventing the cooling night and impurities containing destructive dust from entering the shaft (1); in order to ensure the airtightnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com