Piston pump for liquefied gas

a technology of liquefied gas and pump, which is applied in the direction of pump, positive displacement liquid engine, machine/engine, etc., can solve the problems of reducing the volume of propane, reducing the service life of the seal, so as to achieve the effect of increasing the volum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

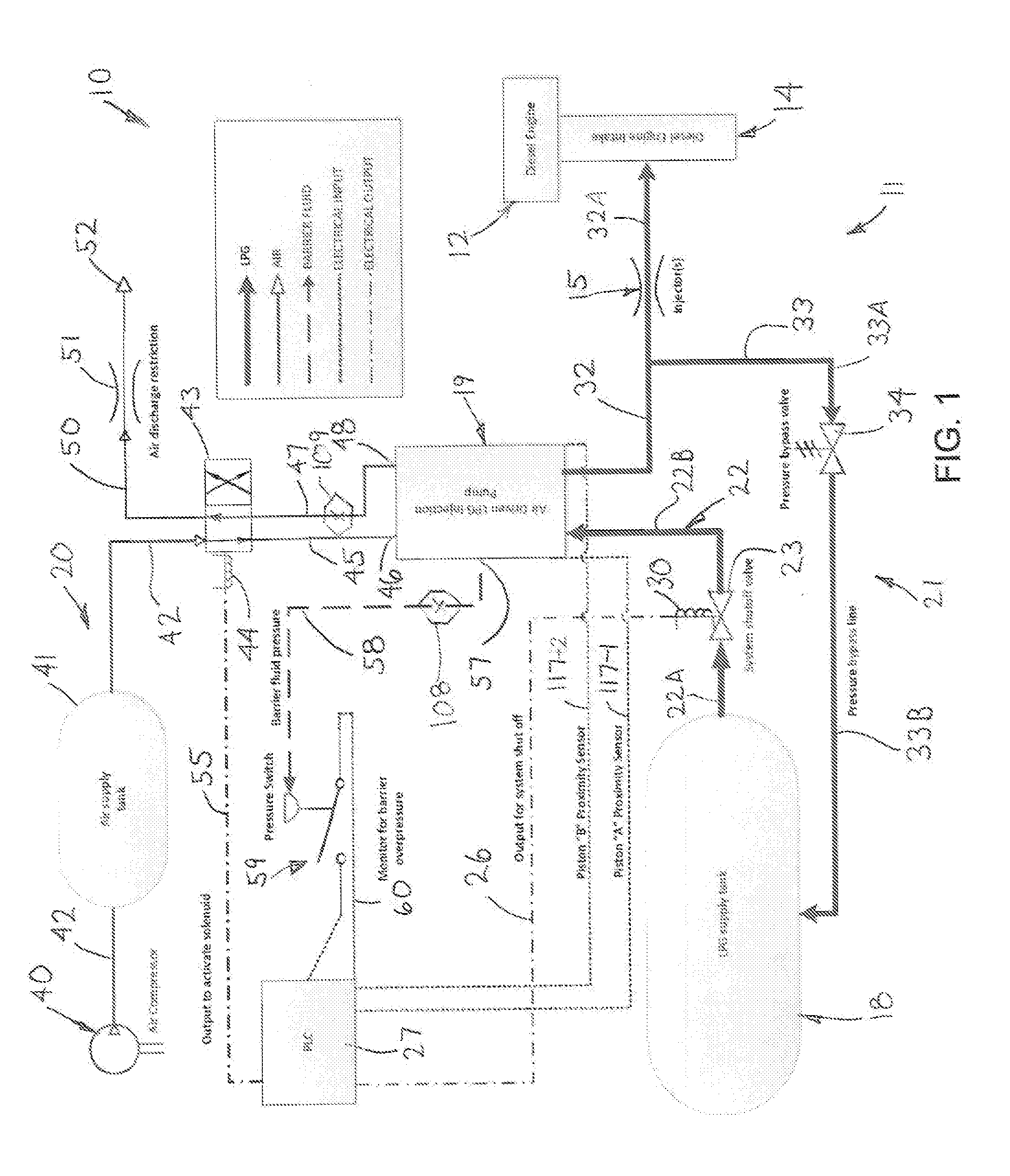

[0024]Referring to FIG. 1, the invention generally relates to a fuel supply system 10 for a vehicle which is generally designated by reference numeral 11 in FIG. 1. This vehicle 11 may be any conventional vehicle, but typically is a truck or the like in which a supplemental fuel, such as Liquefied Petroleum Gas (LPG or propane) or an LPG / Butane mix, is injected into the engine to improve performance thereof.

[0025]As to the vehicle 11, this vehicle 11 is powered by a conventional diesel engine 12, which includes a diesel engine intake 14 that may be constructed in the form of a fuel header or manifold. This engine intake 14 is supplied through one or more fuel injectors 15 wherein a representative one of such injectors 15 is illustrated in FIG. 1. For the diesel engine 12, it is known to inject the LPG into the fuel-air mixture to reduce emissions and increase engine performance. In known systems, the LPG may be pumped using an in-tank submersible turbine pump (not illustrated). The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com