Anti-corrosive wearproof chemical centrifugal pump

A centrifugal pump, chemical technology, applied in the direction of pumps, pump components, non-displacement pumps, etc., can solve the problems of wear and corrosion, high solid content of the medium, unreasonable sealing structure, etc., and achieve long sealing life and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

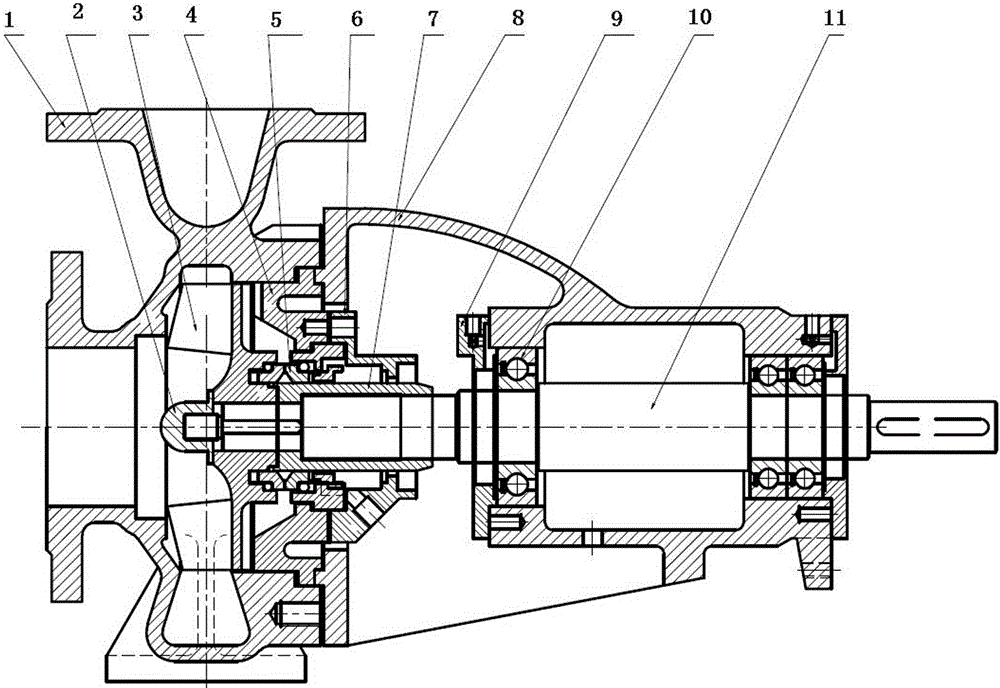

[0028] Such as figure 1 As shown, the corrosion-resistant and wear-resistant chemical centrifugal pump of the present invention includes a pump body 1, an impeller nut 2, an impeller 3, a pump cover 4, a mechanical seal group 5, a sealing box 6, a shaft sleeve 7, a bracket 8, a bearing pressure Cover 9, bearing 10, pump shaft 11 and suspension bracket; pump body 1 and suspension bracket are connected to the base by bolts; pump body 1 is fixed on bracket 8 by bolts, mechanical seal group 5 includes mechanical seal dynamic ring and mechanical Seal the static ring, wherein the mechanical seal dynamic ring is set on the impeller, the pump cover 4, the seal box 6, and the mechanical seal group 5 are jointly set on the pump shaft 11, and the pump cover 4 and the seal box 6 are connected together by bolts; the mechanical seal The static ring, static ring seat and spring are arranged between the pump cover 4 and the sealing box 6; the shaft sleeve 7 is set on the shaft 11, and the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com