Combined reciprocating sealing device of magnetic liquid, C-shaped slip ring and Y x type seal ring

A magnetic liquid and sealing device technology, which is applied to the sealing of engines, engine components, mechanical equipment, etc., can solve the problems of reciprocating compressor piston rod leakage, etc., and achieve the effect of low surface temperature and long sealing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

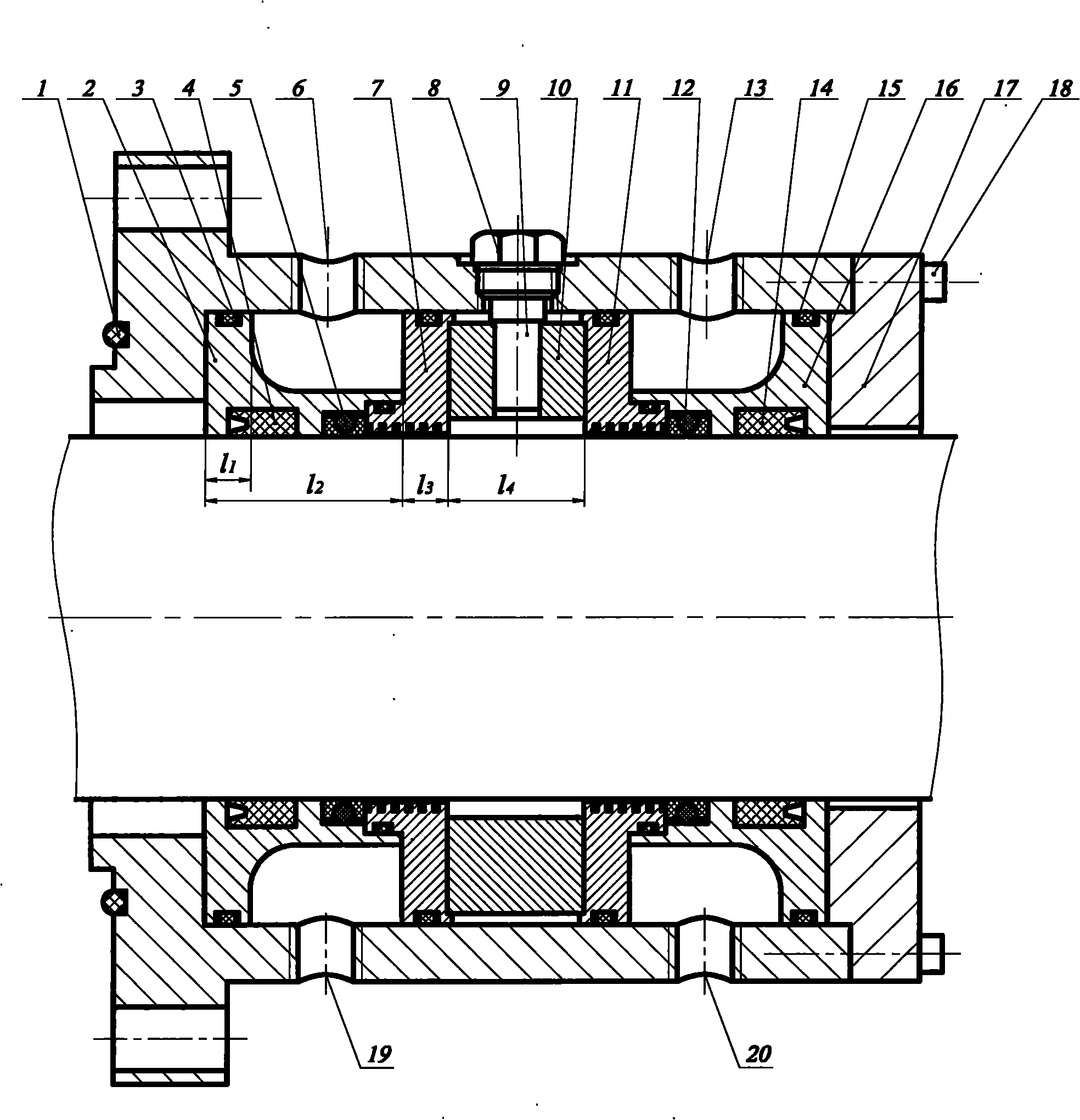

[0019] Control attached figure 1 The specific embodiment of the present invention is described further:

[0020] A combined reciprocating sealing device of magnetic liquid, C-type slip ring and Yx-type sealing ring. The connection between the parts constituting the device is as follows: the first "O"-shaped rubber sealing ring 3 is installed outside the first fixed seat 2 In the annular groove on the circular surface, the first Yx-type sealing ring 4 is installed in the annular groove on the left side of the inner ring surface of the first fixed seat 2, and the first C-type slip ring 5 is installed in the right side of the inner ring surface of the first fixed seat 2. in the annular groove on the side.

[0021] Put the second "O" type rubber sealing ring 15 into the annular groove on the outer surface of the second fixing seat 16, and put the second Yx type sealing ring 14 into the annular groove on the right side of the inner ring surface of the second fixing seat 16 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com