Flying device

A technology of flight equipment and equipment, which is applied in the direction of aircraft, offensive equipment, aircraft parts, etc., can solve problems such as ineffective effects, and achieve the effects of improving flexibility, improving flexibility, and reducing fluid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

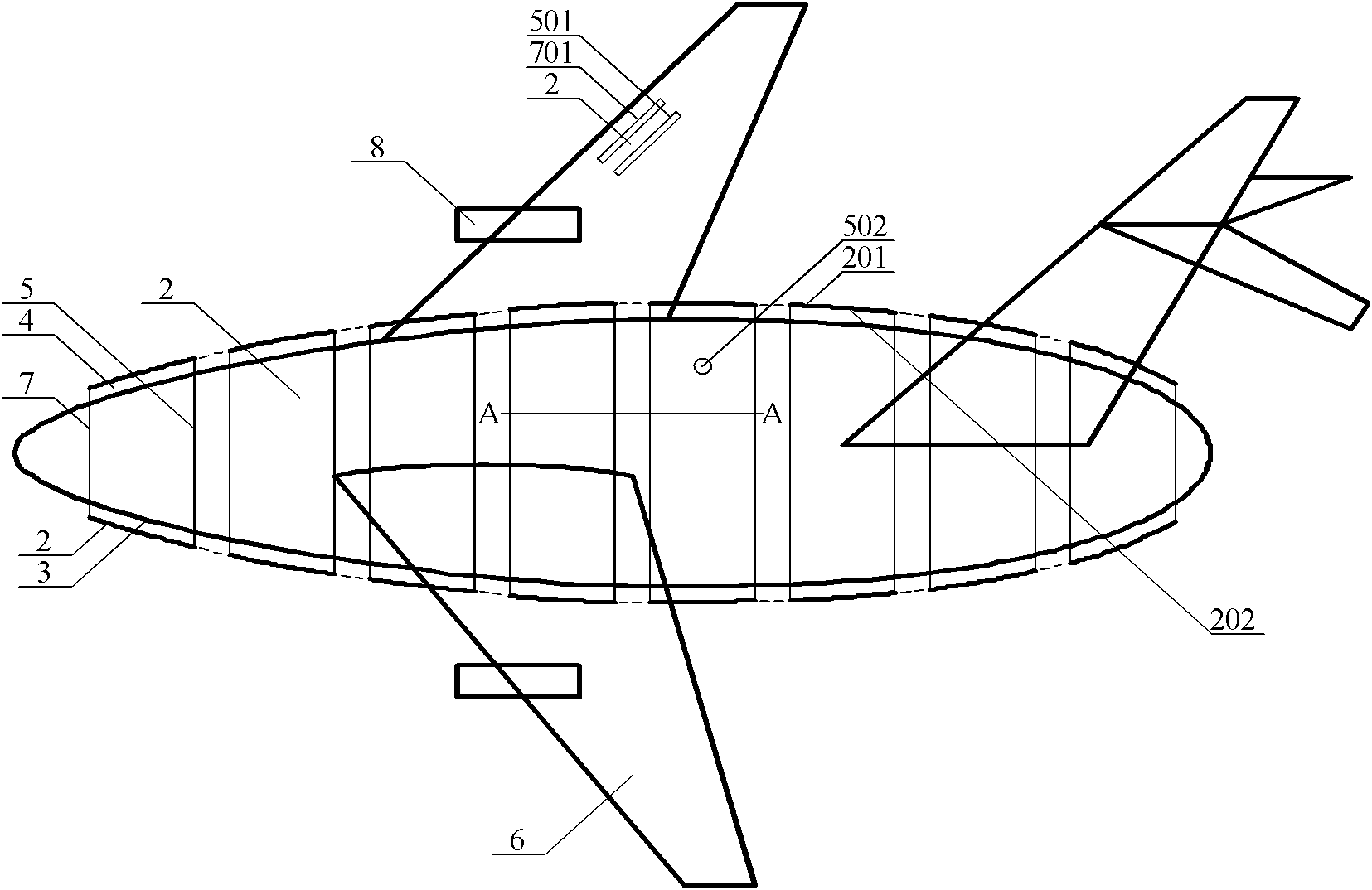

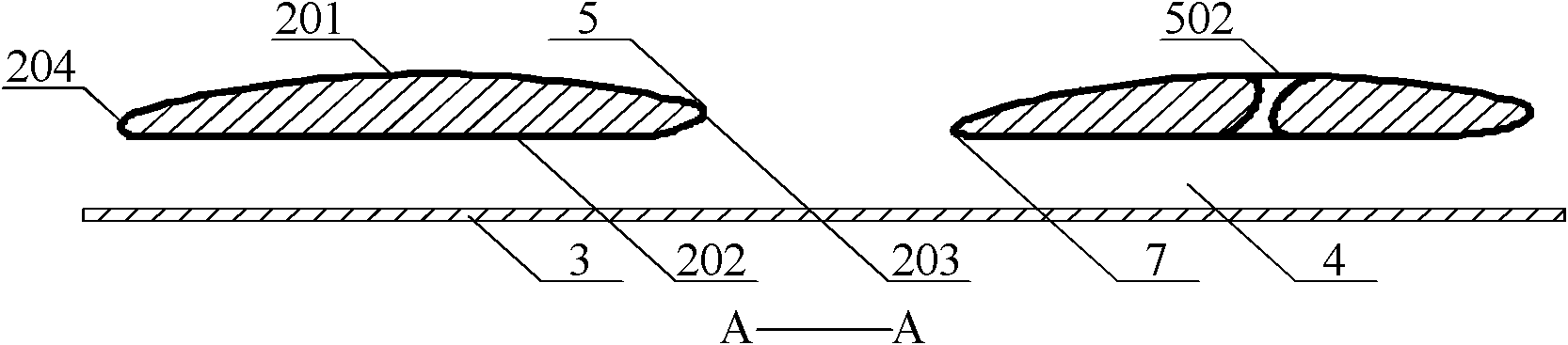

[0082] Such as Figure 1-3 As shown, different from Embodiment 1, a spoiler layer 601 formed by a plurality of spoilers is added on the upper surface of the wing 6, and an air passage 401 is formed between the upper surface of the wing 6, and the spoiler 2 The front side is a strip-shaped inlet 701, and the rear side is connected with a strip-shaped inlet 501. The outer surface 201 of the spoiler 2 is an arc surface, and the inner surface 202 is a plane. When the fluid passes through the spoiler layer 601, the fluid flows from the inlet 701 Introduced through the air channel 401 through the inner surface 202 of the plane and then exported from the outlet 501, after the fluid passes through the spoiler 2, the inner and outer surfaces of each spoiler 2 have a pressure difference due to different paths, so that the air channel 401 passes through the evenly distributed The inlet and outlet of the inlet and outlet, the high pressure area generated by the low flow rate in it is tran...

Embodiment 3

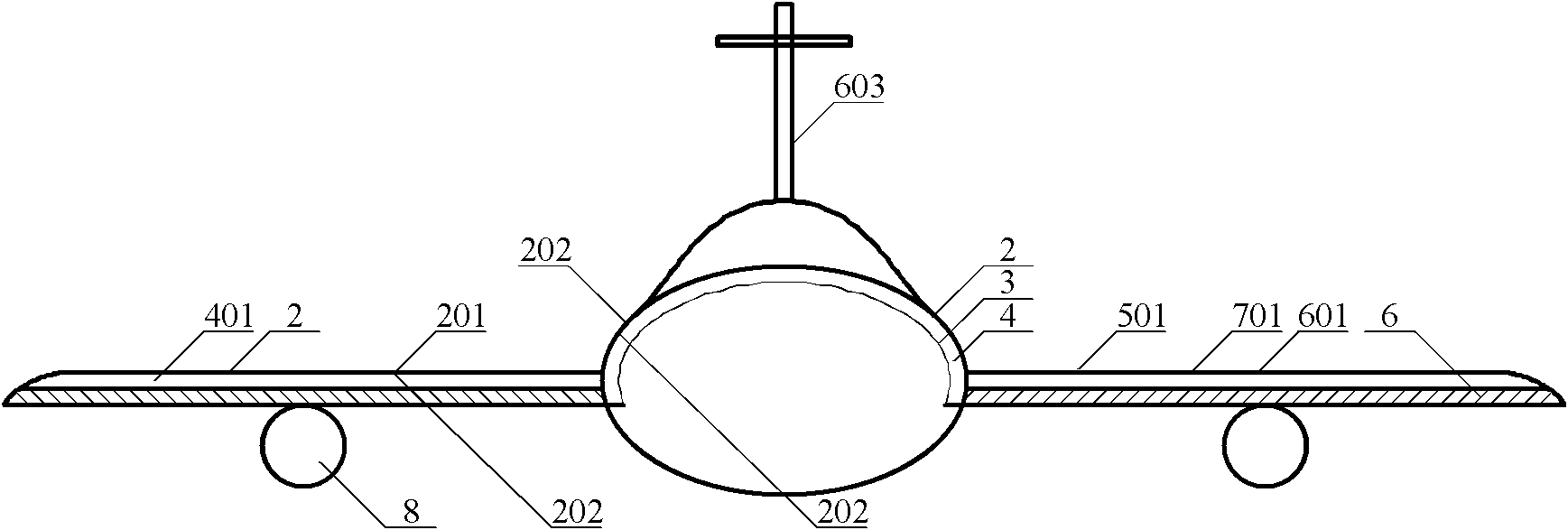

[0090] Such as Figure 4 Shown, different from embodiment 1 is that there is no wing, and engine 8 is located at left and right fuselage both sides, and empennage 602 is established at the rear to control direction.

[0091] After removing the wing, the volume of the aircraft is greatly reduced, and the resistance is also greatly reduced. A plurality of annular spoilers 2 surround the upper half of the fuselage, because the surface area formed by the inner and outer layers of the upper half of the fuselage by the plurality of spoilers is greater than The lift generated by traditional wings is no less than that of ordinary airplanes. More importantly, the pressure and friction generated by the fluid resistance that wraps tightly around the fuselage like a python is greatly reduced, which improves the speed of the aircraft and saves energy. A plurality of spoilers 2 may also be arranged on the upper surface of the empennage 602 .

Embodiment 4

[0093] Such as Figure 5 As shown, different from Embodiment 3, front wings 603 are arranged on both sides of the front end to form a canard layout, but the front and rear wings are smaller than traditional aircraft. On the left and right sides or bottom of the lower half (not pictured).

[0094] The fuselage and wings of the aircraft generate lift at the same time, which greatly increases the lift of the aircraft, increases the carrying capacity, reduces fluid resistance, reduces energy consumption, and increases the flight radius. When the flight angle of attack is 60°-70°, multiple Spoiler 2 forms inner and outer two layers of fluid layers to infiltrate each other, and there will be no danger of fluid breaking away from the fuselage like a smooth surface, thereby improving the flexibility and combat effectiveness of the aircraft.

[0095] Another embodiment, different from the above, is that the spoiler 2 surrounds the fuselage.

[0096] Another embodiment, different from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com