Technology of laying transport rails with track skeletons

A technology for transporting tracks and processes, applied in tracks, track laying, track maintenance, etc., can solve problems such as the inability to meet normal construction requirements, and achieve the effects of orderly construction, high efficiency, wide application range, and high degree of mechanization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation steps are as follows:

[0031] 1. If Figure 9 , rail row assembly:

[0032] (1) Use No. 3 equipment (rail assembly tie rod) to connect two long steel rails and adjust the gauge;

[0033] (2) Install the sleepers on the long steel rails according to the designed spacing and assemble them into a rail row.

[0034] 2. If Figure 9 , Rail row loading and transportation:

[0035] (1) Laying the first rail row and the second rail row: use lifting equipment to lift the first rail row and the second rail row to the predetermined location, and the direction along the line from the first rail row to the second rail row is the rail row The laying direction; adjust the first rail row and the second rail row to make the rails butt, and use the No. 4 equipment (rail row joint connection clamp) to clamp the rails on both sides of the butt joint;

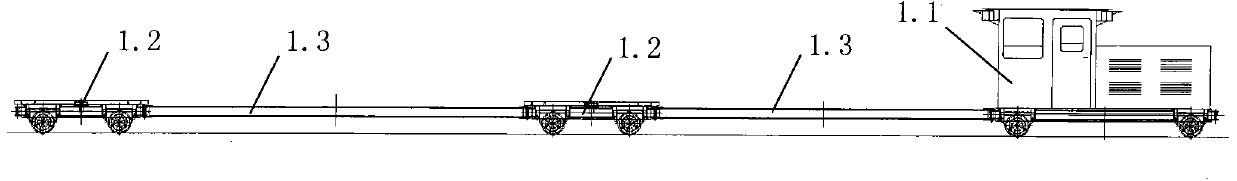

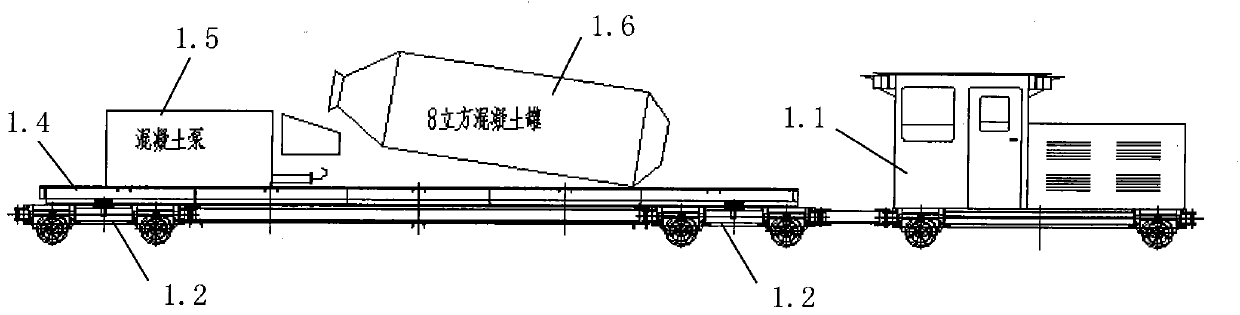

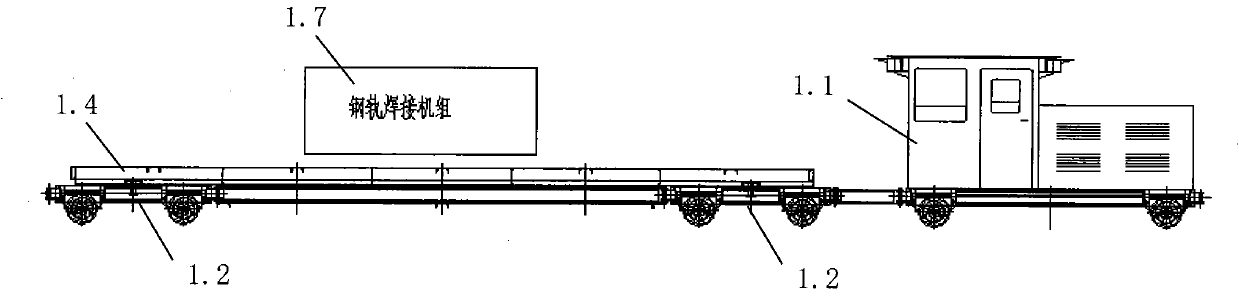

[0036] (2) Assembling No. 1 equipment (rail car for rail material transportation): use lifting equipment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com