Continuous multi-unit single meter splitting machine

A technology of meter machine and unit order, which is applied in the field of continuous multi-unit order sorting machine, which can solve the problems that multi-unit orders cannot be automatically divided into single-unit orders, etc., and achieve the effect of stable operation and high efficiency of order sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

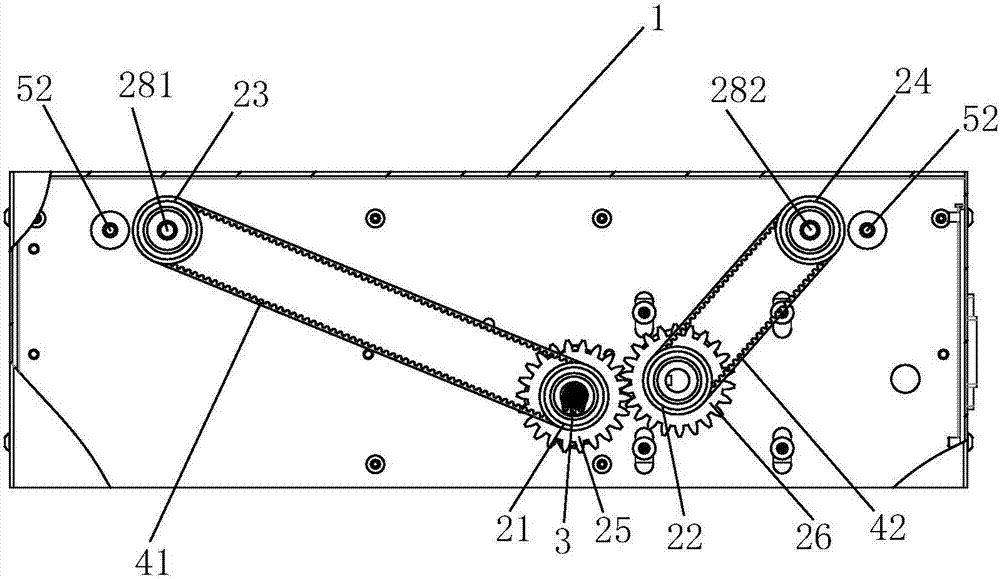

[0026] This embodiment provides a continuous multi-connected single meter splitter, the motor is assembled and connected to the inside of the chassis 1, and the driving wheel 21, the first driven wheel 22, the second driven wheel 23 and the third driven wheel 24 are hinged to the chassis 1 through bearings Inside, the output shaft 3 of the motor is assembled and connected to the driving wheel 21, the first gear 25 is assembled and connected to the driving wheel 21, the second gear 26 is assembled and connected to the first driven wheel 22, the first gear 25 meshes with the second gear 26, and the driving wheel 21 Connect the second driven wheel 23 through the first conveyor belt 41, the first driven wheel 22 connects the third driven wheel 24 through the second conveyor belt 42, the second driven wheel 23 and the third driven wheel 24 are all assembled to connect the paper clip wheel 27; The assembly includes two first transmission shafts 51 and two second transmission shafts 5...

Embodiment 2

[0028] The difference between this embodiment and Embodiment 1 is that the second driven wheel 23 is assembled and connected with the first connecting shaft 281, the two ends of the first connecting shaft 281 are assembled and connected with the paper clamping wheel 27, and the third driven wheel 24 is assembled and connected with the second The connecting shaft 282 and the two ends of the second connecting shaft 282 are assembled to connect the clamping wheel 27 . In this way, the clamping wheel 27 on one side engages the two ends of the first joint 621 and drives the first joint 621 to move to the left side of the chassis 1 smoothly, and the paper clamping wheel 27 on the other side engages the two ends of the second joint 622. end and drives the second joint 622 to move to the right side of the chassis 1 smoothly. This makes the single operation run more smoothly.

Embodiment 3

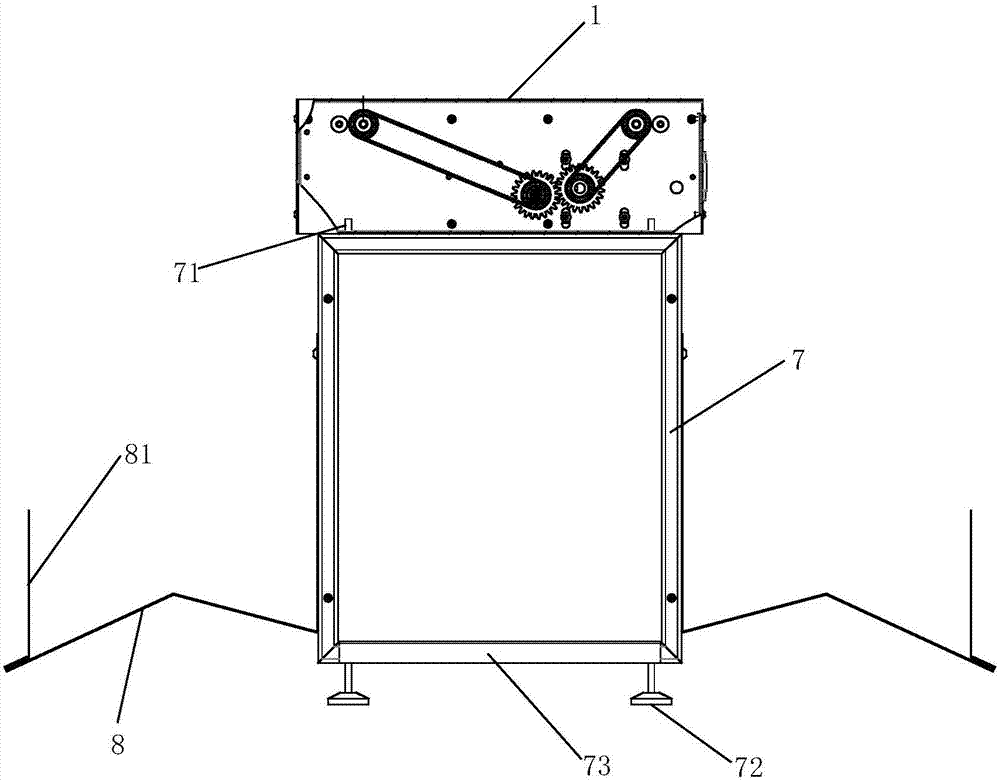

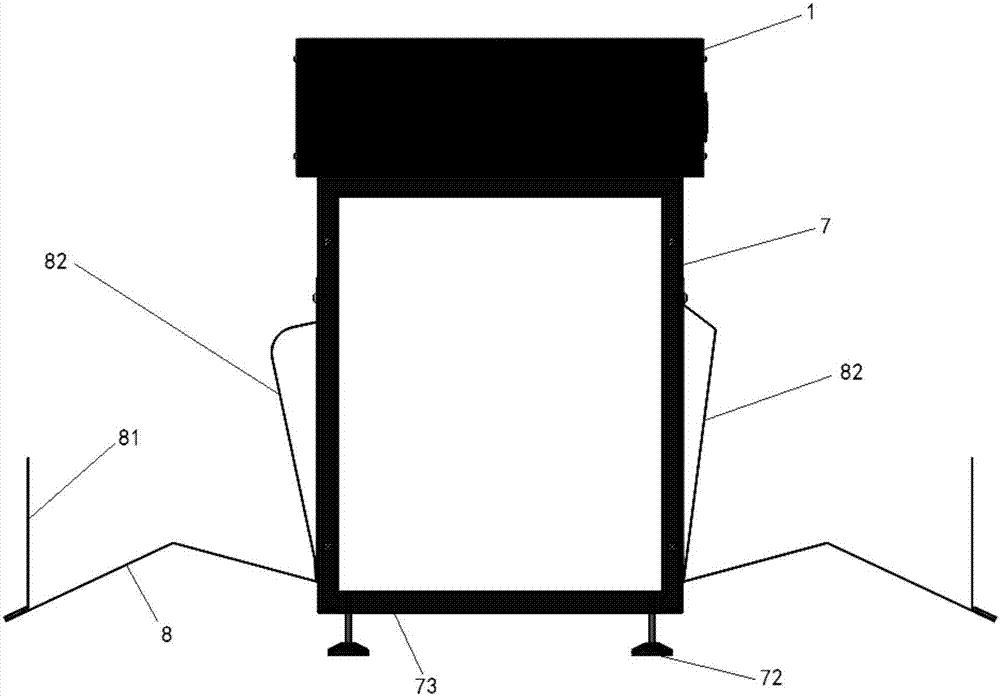

[0030] The difference between this embodiment and Embodiment 2 is that it also includes a frame 7, the upper part of the frame 7 is fixedly connected with a connecting pin 71, and the lower part of the chassis 1 is provided with a connecting hole that can be engaged with the connecting pin 71, so that The continuous multi-unit single-distributing machine in this embodiment is convenient for disassembly and assembly, and is convenient for logistics and transportation. The lower part of the frame 7 is fixedly connected with an anchor 72 to support the frame 7 more stably. The bottom of the frame 7 is fixedly connected with a paper holder 73, on which the folded multiple sheets 61 can be placed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com