Roll-on/slide-off mounting method of large steel structure truss

An installation method and steel structure technology, applied in the direction of building structure, construction, and building material processing, etc., can solve the problems of inconvenient installation, large unsafe factors, and large unsafe factors, so as to achieve convenient construction and save energy. The effect of construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

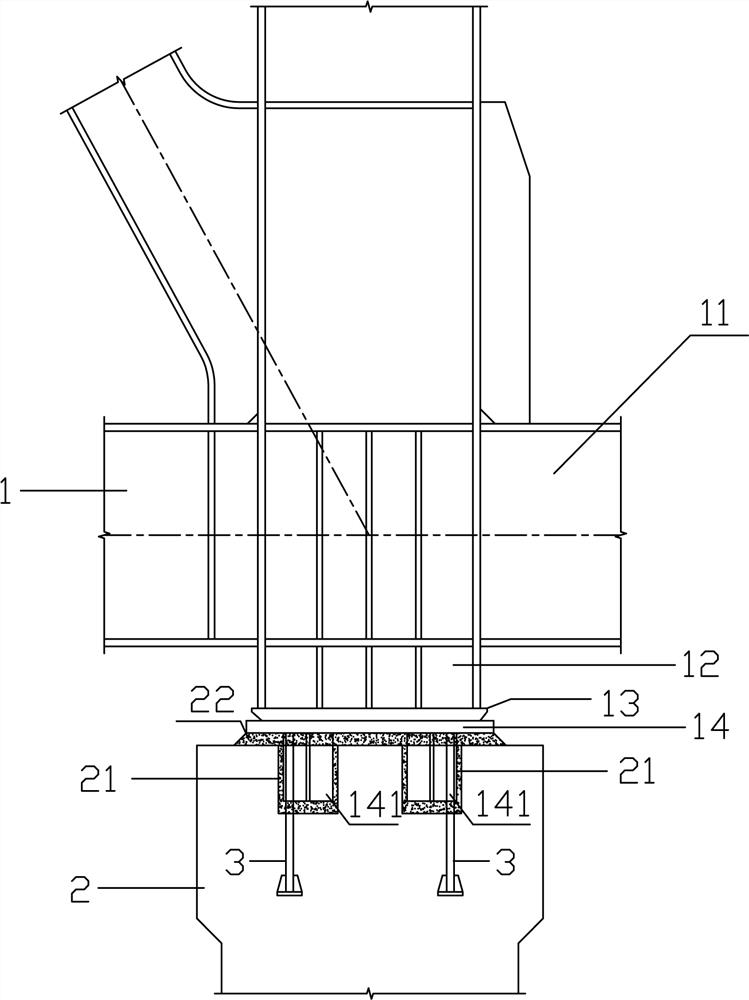

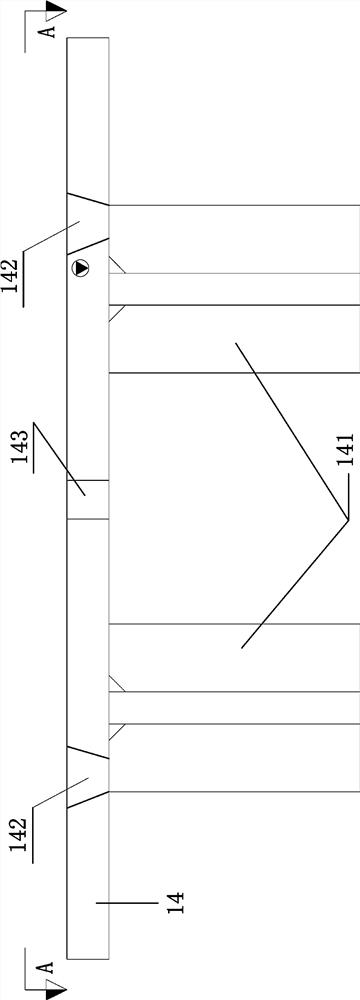

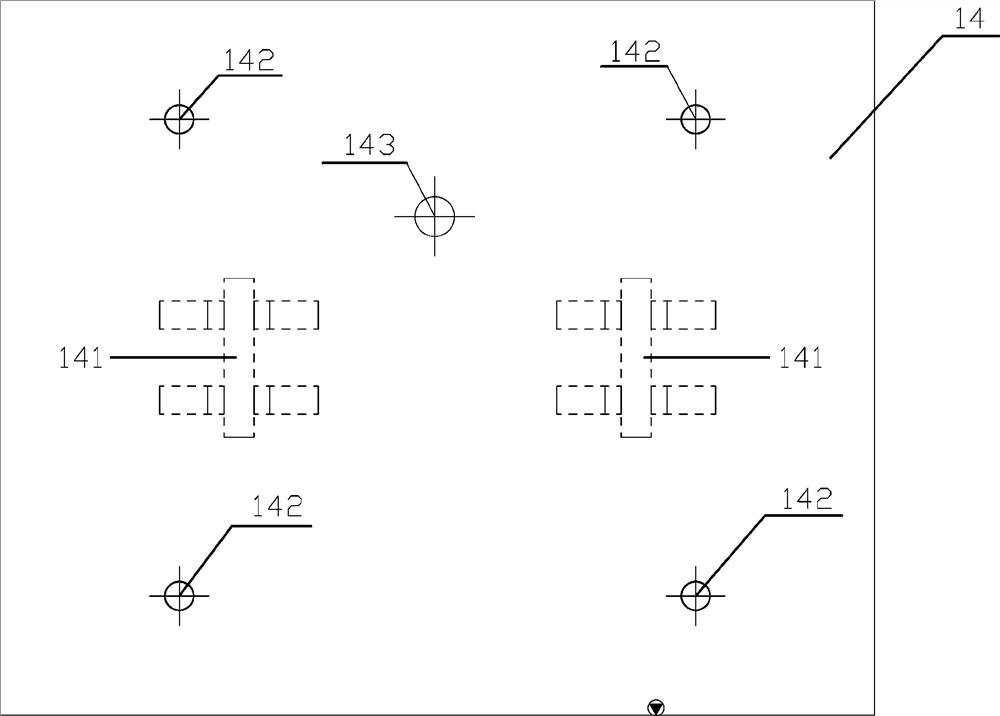

[0021] A roll-on / skid installation method for large steel structure trusses, such as Figure 1 ~ Figure 3 As shown, implement in sequence as follows:

[0022] ① Weld the steel truss 11 and the steel column 12 to form the truss member 1, fix the first column foot plate 13 at the bottom of the steel column 12, bind the steel bars on the concrete column 2, and place it vertically on the top surface of the concrete column 2 after measurement and positioning Install at least four pre-embedded bolts 3, each pre-embedded bolt 3 on the concrete column 2 is connected in turn by angle steel or steel bars so that each pre-embedded bolt 3 is connected into a whole pre-embedded bolt frame, and the pre-embedded bolts The steel bars in the frame and the concrete column 2 are spot-welded firmly to prevent deviation when pouring concrete, and at least two shear keyways 21 are reserved on the top of the concrete column 2;

[0023] ② After the concrete curing of the concrete column 2 is complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com