Hanging cage frame for high-sky large-size flue box body heat preservation construction

A large-volume, flue technology, which is applied to scaffolding supported by housing structures, accessories of scaffolding, and housing structure support, etc., can solve problems such as inconvenience, shorten the construction period, speed up the construction speed, and solve the effect of narrow site.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The hanging cage used for the thermal insulation construction of the high-altitude large-volume flue box of the present invention includes an external hanging frame and a springboard.

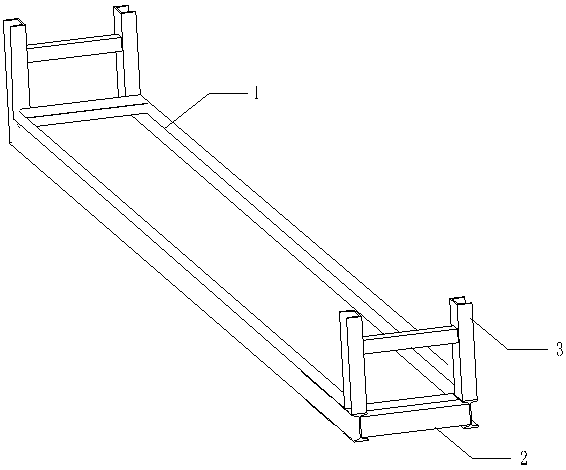

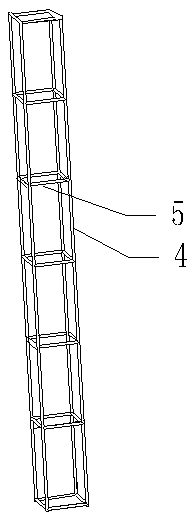

[0026] see now figure 1 and figure 2 , figure 1 It is a schematic diagram of a rectangular frame structure according to an embodiment of the present invention, figure 2 It is a schematic diagram of the inline side truss structure of the embodiment of the present invention. The external hanger is a number of well-shaped steel structure frames, and several well-shaped steel structure frames are arranged at intervals around the flue box, including a rectangular frame at the top, in-line side trusses on both sides and in-line trusses at the bottom. Bottom truss, wherein: the rectangular frame at the top is a rectangular frame made of I-shaped steel made of two long sides 1 of rectangular frames and two short sides 2 of rectangular frames. The I-shaped frame 3 at the end of the rectangu...

Embodiment 2

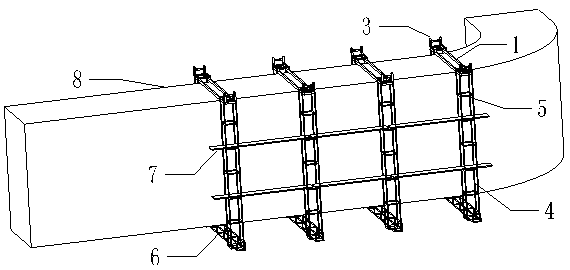

[0030] image 3 It is a schematic diagram of the use state of the hanging cage used for the thermal insulation construction of the high-altitude and large-volume flue box according to the embodiment of the present invention. In the present embodiment, four well-shaped steel frame frames and two rows of springboards 7 are used to jointly form a hanging cage frame. Four well-shaped steel frame frames are arranged at intervals around the flue box 8, including a rectangular frame at the top, inline side trusses on both sides and inline bottom trusses at the bottom. All the other structures of this embodiment are the same as Embodiment 1. The advantage of this embodiment is that the construction method of the hanging cage not only meets other professional constructions in a limited space, but also saves the erection of scaffolding, and can also fully meet the needs of high-altitude and large-volume flue construction, and speed up the construction progress.

[0031] The present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com