A kind of preparation method of artificial reef concrete material with steel slag as main raw material

An artificial reef and concrete technology, applied in the field of steel slag treatment technology and marine environmental protection, can solve problems such as high cost and complex process, achieve significant resource benefits and expand the scope of marine pastures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

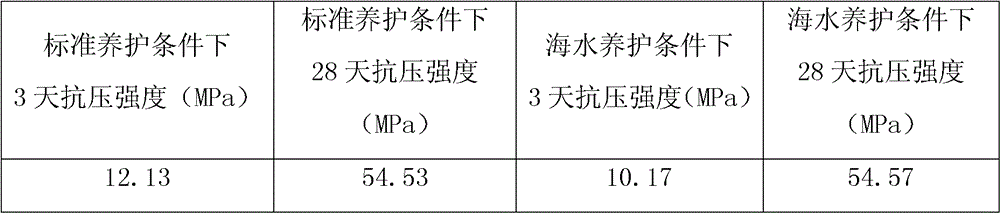

[0032] The weight percentages of steel slag, slag, cement clinker, and desulfurized gypsum in the cementitious material are: 50%, 30%, 10%, and 10%. Add 560kg of cementitious material, 873kg of fine aggregate, 1303kg of coarse aggregate, 166kg of water, and 1.7kg of PC high-efficiency water reducer to the cubic meter artificial fish reef concrete. Age 3 days, 28 days) or seawater curing (standard curing 1 day demolition, curing to the total age of 3 days, 28 days) to obtain higher strength artificial reef concrete, its main performance indicators are shown in Table 1 Show.

[0033] Table 1 uses the main strength index of artificial fish reef concrete obtained in Example 1

[0034]

Embodiment 2

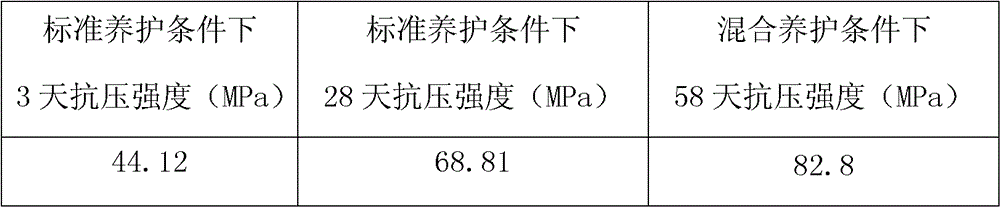

[0036] The weight percentages of steel slag, slag, cement clinker, and desulfurized gypsum in the cementitious material are: 10%, 70%, 10%, and 10%. Add 560kg of cementitious material, 873kg of fine aggregate, 1303kg of coarse aggregate, 166kg of water, and 1.7kg of PC high-efficiency water reducer to the cubic meter of artificial fish reef concrete. 3 days, 28 days) and mixed curing (standard curing 1 day demolition, standard curing to 28 days after the age, seawater curing to the total age of 58 days) conditions can get higher strength artificial reef concrete, the main Performance indicators are shown in Table 2.

[0037] Table 2 uses the main strength index of artificial fish reef concrete obtained in Example 2

[0038]

Embodiment 3

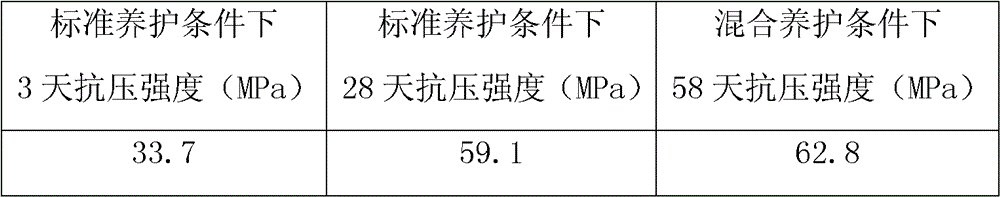

[0040] The weight percentages of steel slag, slag, cement clinker and desulfurized gypsum in the cementitious material are: 15%, 79%, 1%, 5%. Add 560kg of cementitious material, 873kg of fine aggregate, 1303kg of coarse aggregate, 166kg of water, and 1.7kg of PC high-efficiency water reducer to the cubic meter of artificial fish reef concrete. 3 days, 28 days) and mixed curing (standard curing 1 day demolition, standard curing to 28 days after the age, seawater curing to the total age of 58 days) conditions can get higher strength artificial reef concrete, the main Performance indicators are shown in Table 3.

[0041] Table 3 uses the main strength index of artificial fish reef concrete obtained in embodiment 3

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com