Safe crush-resistance assembly-type steel-structure elevator well

An elevator shaft and prefabricated technology, applied to building components, building structures, vertical pipes, etc., can solve the problems of high cost, long construction period, and long time consumption, so as to improve the construction speed, improve the supporting performance, reduce the workload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

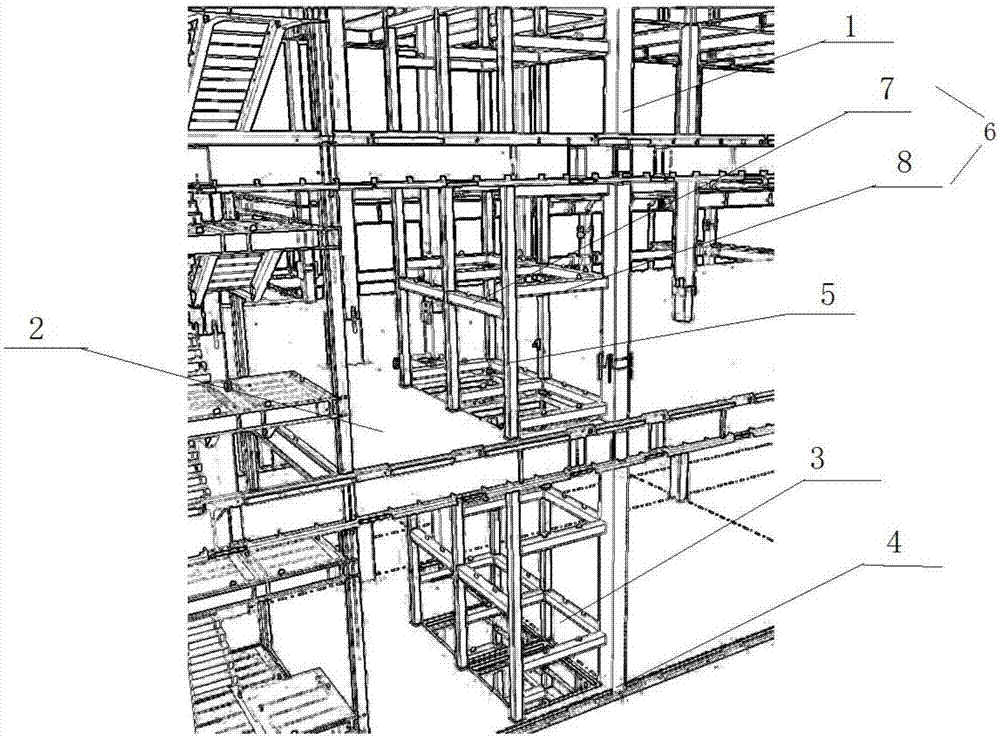

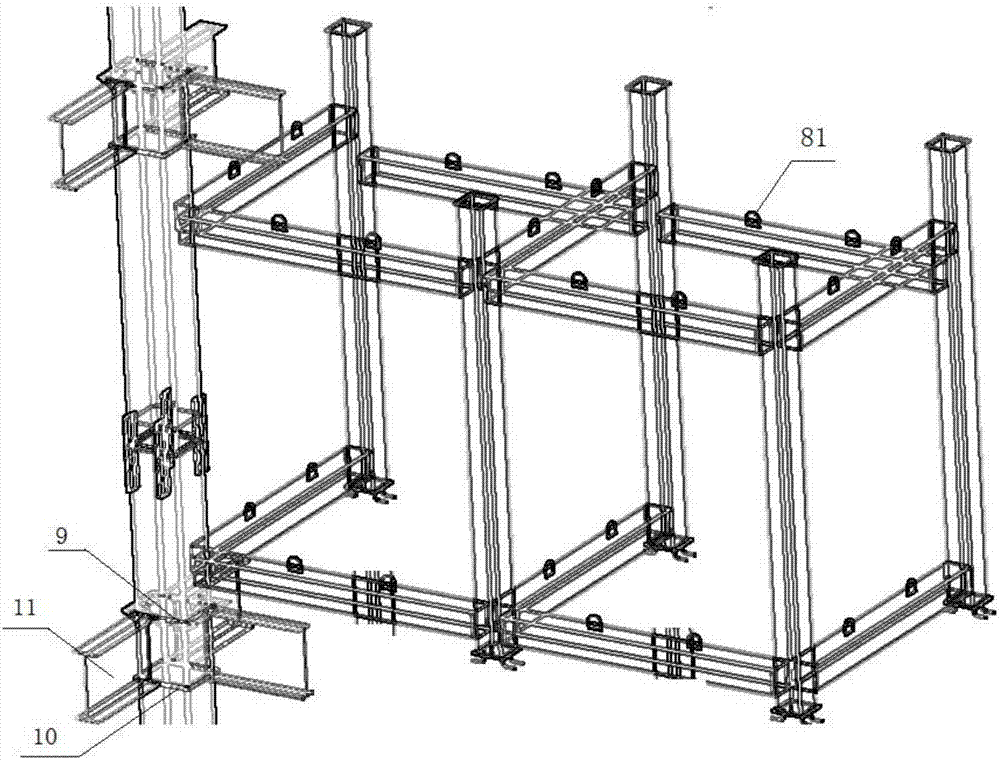

[0031] As shown in the figure, a compression-resistant and safe assembled steel structure elevator shaft includes: frame column 1, floor slab 2 and elevator shaft 3;

[0032] The relationship between the above components is as follows:

[0033] The frame column 1 and the floor 2 are connected by embedded parts, and the frame column 1 and the roof 4 are directly welded to the roof beam by using a head plate, and the elevator shaft 3 is provided with an elevator beam 5 and a frame beam 6, wherein , the frame beam 6 is provided with a first ring beam 7 and a second ring beam 8, the elevator beam 5 is located at the position of the elevator beam and is provided with a first ring beam 7 according to the height of the elevator door, which is located A second ring beam 8 is provided on the side, and a lifting lug 81 is provided on the second ring beam 8, and a gypsum board is provided on the well wall of the elevator shaft 3, and the gypsum board is a light steel keel gypsum board. ...

Embodiment 2

[0038] As shown in the figure, a compression-resistant and safe assembled steel structure elevator shaft includes: frame column 1, floor slab 2 and elevator shaft 3;

[0039] The relationship between the above components is as follows:

[0040] The frame column 1 and the floor 2 are connected by embedded parts, and the frame column 1 and the roof 4 are directly welded to the roof beam by using a head plate, and the elevator shaft 3 is provided with an elevator beam 5 and a frame beam 6, wherein , the frame beam 6 is provided with a first ring beam 7 and a second ring beam 8, the elevator beam 5 is located at the position of the elevator beam and is provided with a first ring beam 7 according to the height of the elevator door, which is located A second ring beam 8 is provided on the side, and a lifting lug 81 is provided on the second ring beam 8, and a gypsum board is provided on the well wall of the elevator shaft 3, and the gypsum board is a light steel keel gypsum board. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com