Directional long-hole group for gas extraction and construction method of directional long-hole

A technology for gas extraction and long drilling, which is applied in drilling equipment and methods, directional drilling, gas discharge, etc., can solve problems such as high cost and poor effect, and achieve high precision, high efficiency, and high drilling construction efficiency. and pore-forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

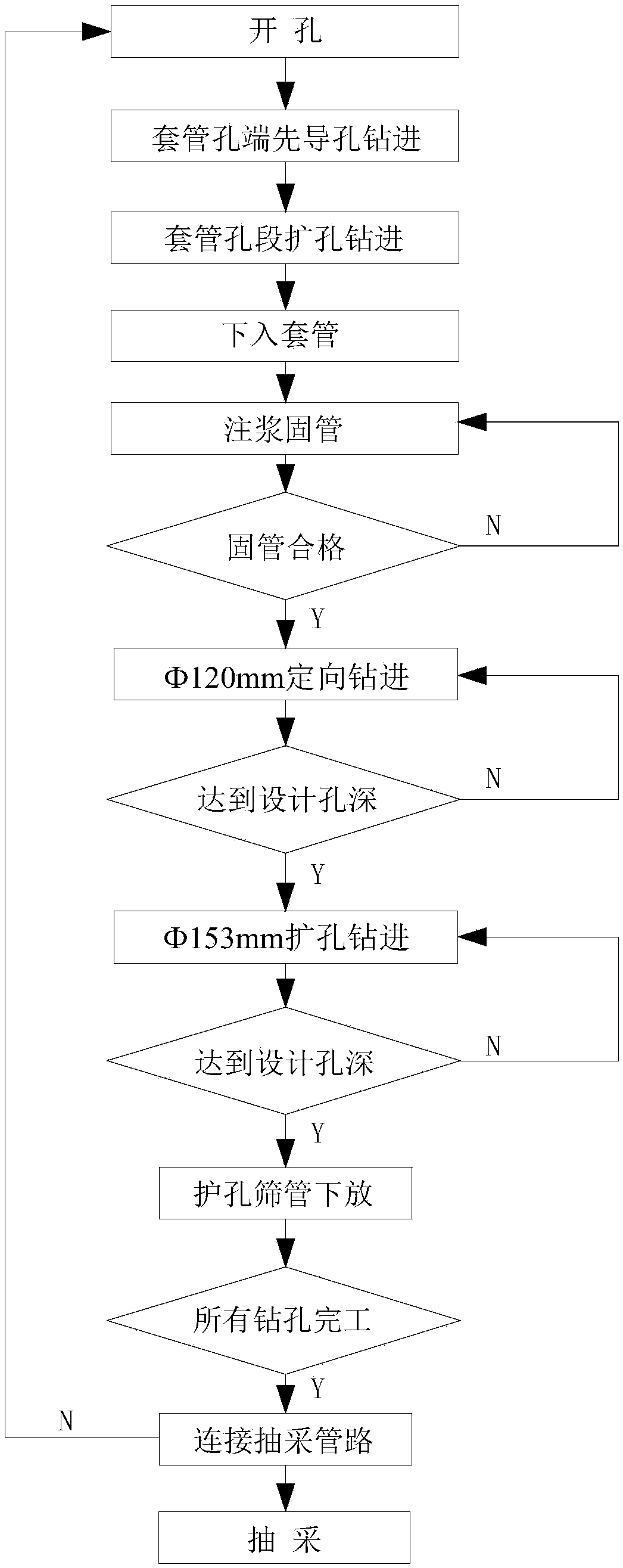

[0022] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

[0023] The general situation of the working face in this embodiment: the strike length is 1937 meters, the inclination length is 260 meters, the roadway is supported by anchor beam net, and the end face is rectangular. The average coal thickness of the coal seam is 4.10 meters, and the normal dip angle of the coal seam is 10-40. Direct top: about 4.19 meters of mudstone, fine sandstone, sandy mudstone; old top: about 3.25 meters of medium sandstone; direct bottom: about 3.6 meters of sandy mudstone, mudstone; old bottom: about 4.65 meters of sandy mudstone.

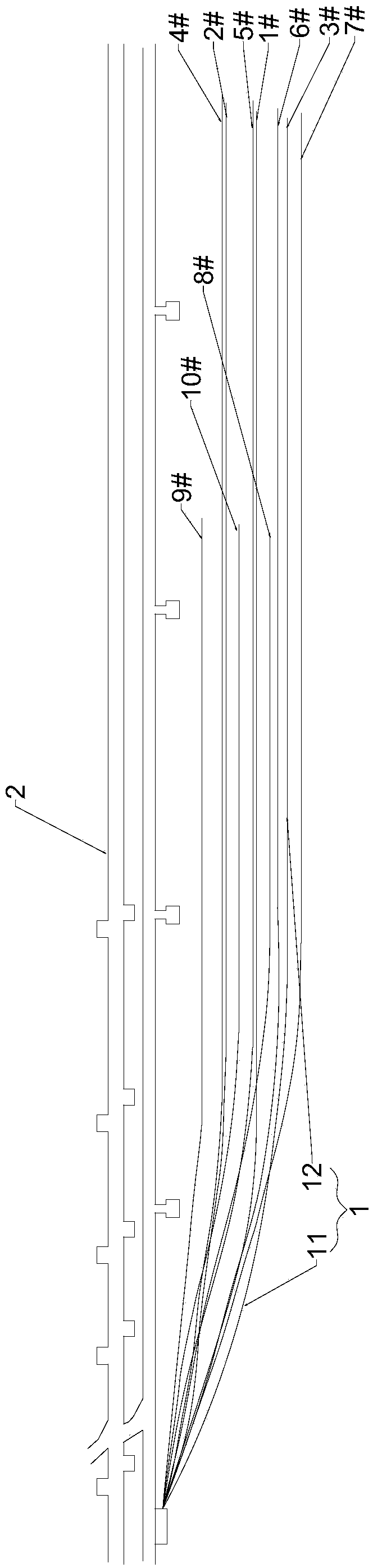

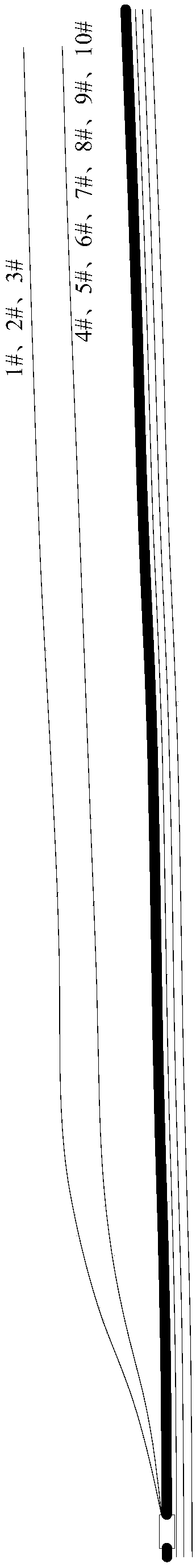

[0024] like figure 1 Shown is a gas drainage directional long borehole group provided in this embodiment, which includes a plurality of directional long boreholes 1 that are staggered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com