Underground diaphragm wall grooving construction method

A technology of underground diaphragm wall and construction method, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of low hole-forming efficiency, slow construction, and poor hole-forming quality, and achieve high hole-forming efficiency and improved Accuracy and efficiency, the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

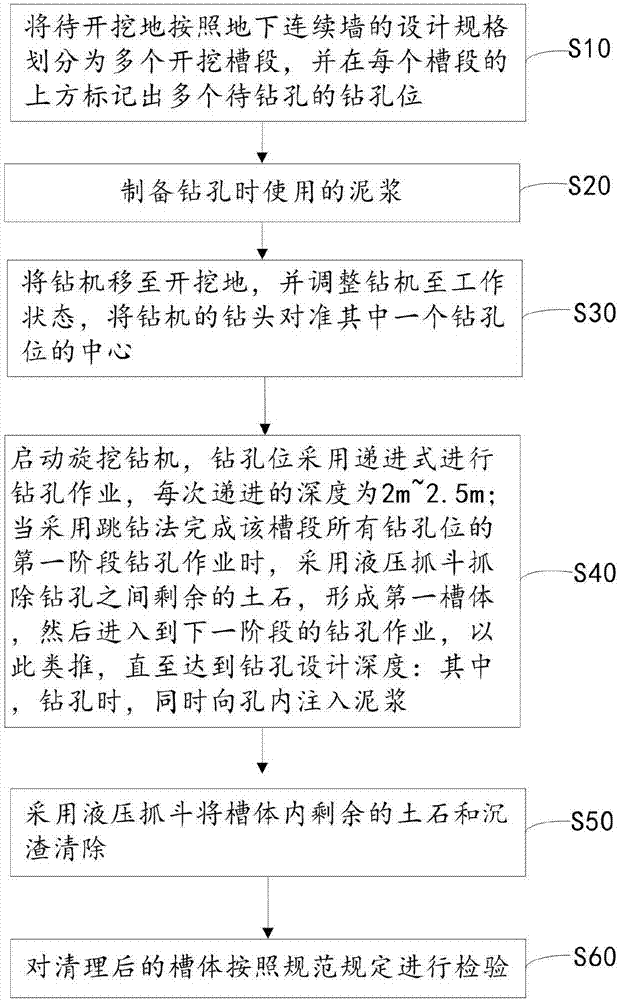

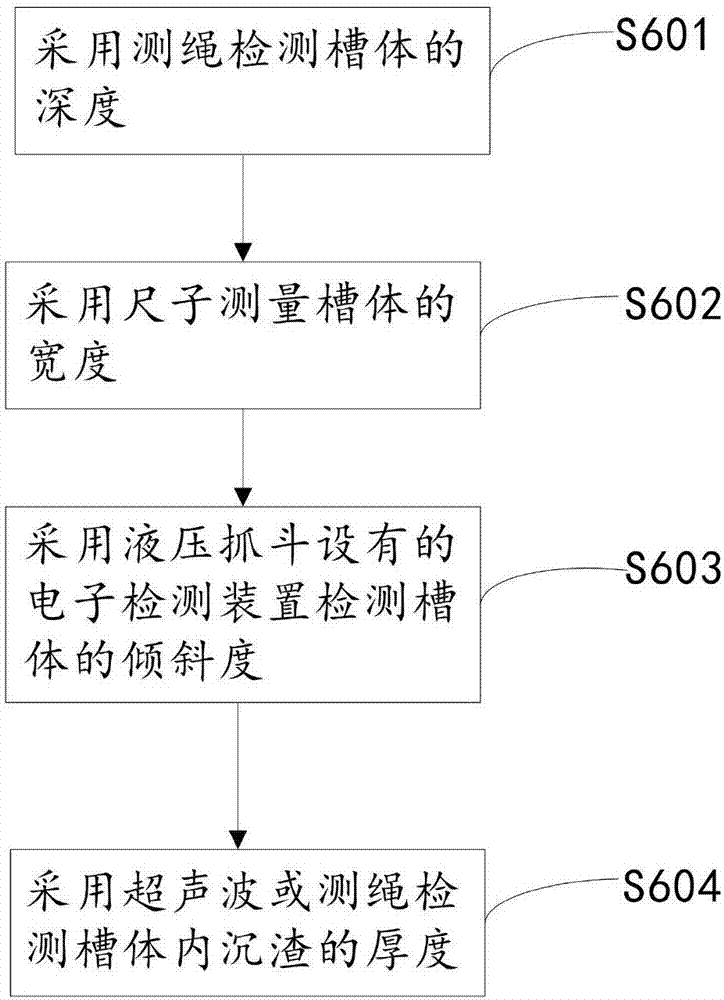

[0029] see Figure 1-4 , the invention provides a construction method for forming grooves in an underground diaphragm wall, the construction method has a specific application at Maju Station of the Kunming Metro, and the method includes:

[0030] S10, dividing the ground to be excavated into a plurality of excavation slot sections according to the design specifications of the underground diaphragm wall, and marking a plurality of drilling positions to be drilled above each slot section;

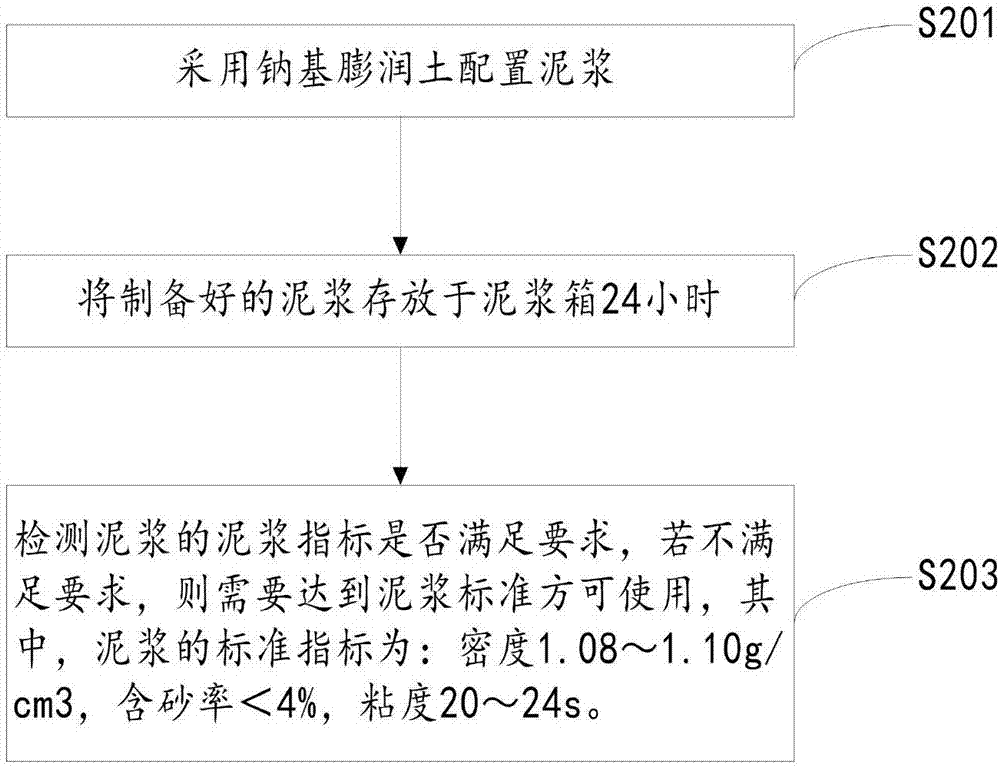

[0031] S20, prepare the mud used when drilling;

[0032] S30. Move the rotary drilling rig to the excavation site, adjust the rotary drilling rig to the working state, and align the drill bit of the rotary drilling rig to the center of one of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com