Forming method for metal surface micro-nano holes through mechanical lapping and lapping and polishing machine

A micro-nano hole and mechanical grinding technology, applied in grinding machine tools, grinding devices, metal processing equipment, etc., can solve the problems of damage to metal surface quality, complex equipment system, high processing cost, and overcome the requirements of corrosion resistance and environmental impact. The problem of contamination, the effect of increasing the specific surface area, and shortening the molding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

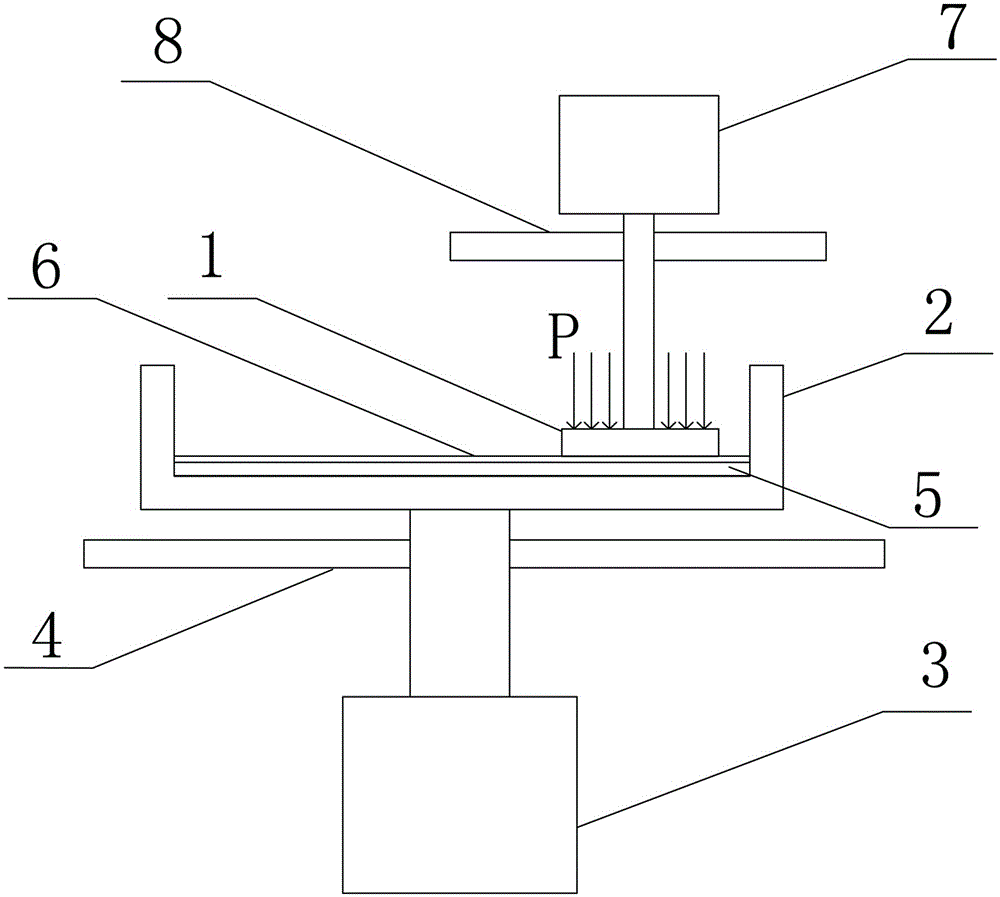

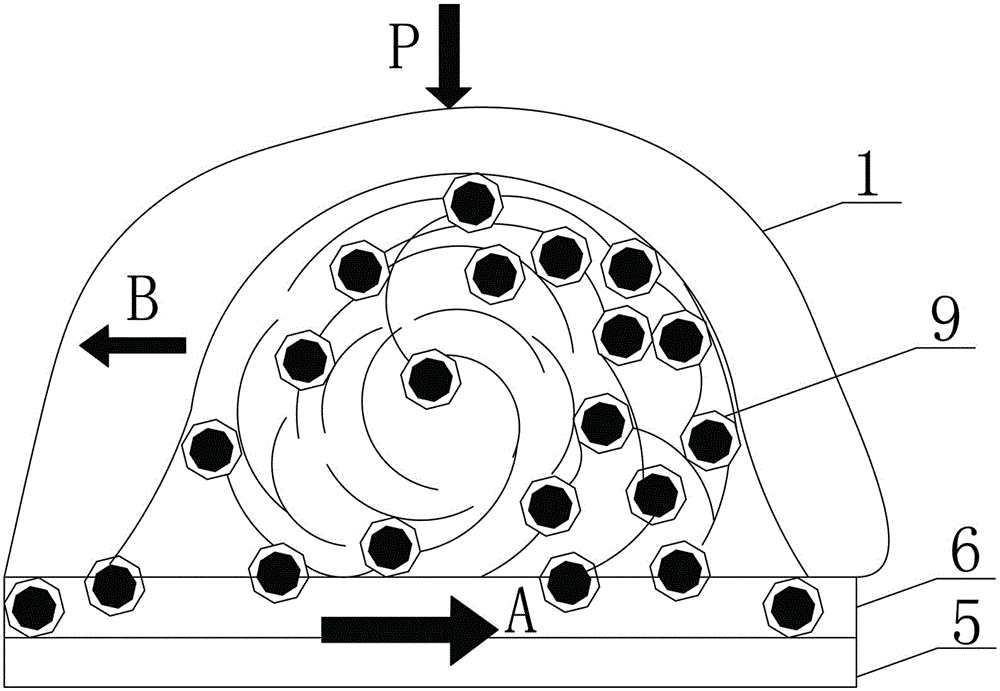

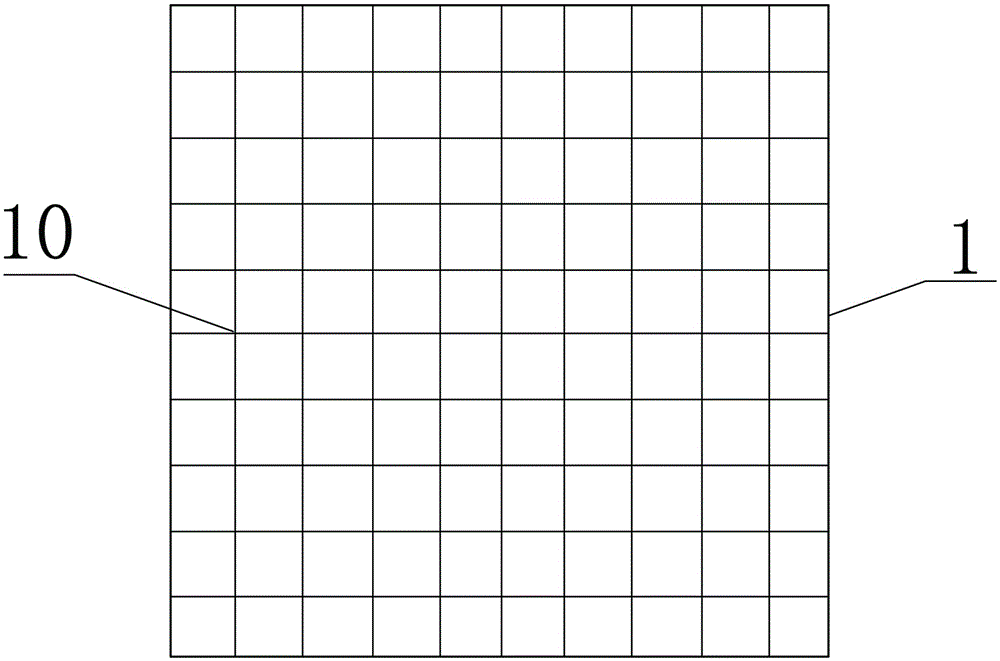

[0034] see Figure 1 to Figure 4 The first embodiment of the present invention provides a method for mechanically grinding micro-nano pores on a metal surface, comprising: providing a grinding and polishing liquid 6 containing abrasive particles 9 and a metal workpiece 1 with a plurality of defects 10 formed on the surface; Under the action of the grinding and polishing liquid 6, the surface of the metal workpiece 1 formed with a plurality of defects 10 is mechanically ground, so that the grinding and polishing liquid 6 entrains the abrasive particles 9 and continuously lands on the metal workpiece 1 Each defect 10 in each defect 10 performs vortex motion to grind the wall surface of the corresponding defect, and continuously washes away from each defect 10 on the metal workpiece 1, thereby forming micro-nano holes at each defect on the metal workpiece 1.

[0035] In this embodiment, the metal workpiece 1 is made of SUS304 stainless steel. The grinding and polishing liquid 6 ...

Embodiment 2

[0040] Embodiment two: basically the same as embodiment one, the difference is:

[0041] The method for forming micro-nano holes by mechanically grinding the metal surface provided in the second embodiment is different from the first embodiment in that the load P applied to the surface of the processed workpiece is different. When the load P=2.97Kg (0.023MPa), other conditions remained unchanged from Example 1, and obtained Figure 5 In the photomicrograph of the surface of the micropores, the diameter of the micropores is about 2-3 μm, and there are no nanopores, and the distribution density of the micropores is slightly smaller than that in Example 1. It shows that under heavy load, the surface removal polishing process is strengthened, so that the nano-holes disappear and only micro-holes are left. Pore forming and surface removal polishing rates of the surface are a competing process, and under heavy loads, the surface removal rate is higher than the surface pore formin...

Embodiment 3

[0042] Embodiment three: basically the same as embodiment two, the difference is:

[0043] The method for forming micro-nano pores by mechanically grinding the metal surface provided in Example 3 is different from Example 2 in that the grinding time is prolonged. When the grinding time was extended to 40 minutes from 20 minutes, other conditions remained unchanged with embodiment two, obtained Image 6 In the photomicrograph of the surface of the micropores, the diameter of the micropores is about 2 μm, which is slightly smaller than that in Example 2, and there are no nano-holes, and the density of the micropores is also reduced. It is further confirmed that the surface removal rate is higher than the surface micropore formation rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com