Patents

Literature

41results about How to "Avoid ablative damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

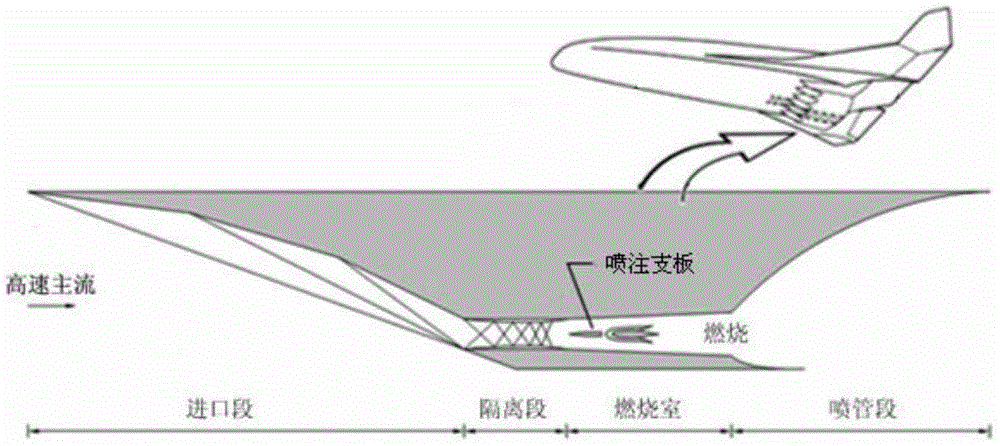

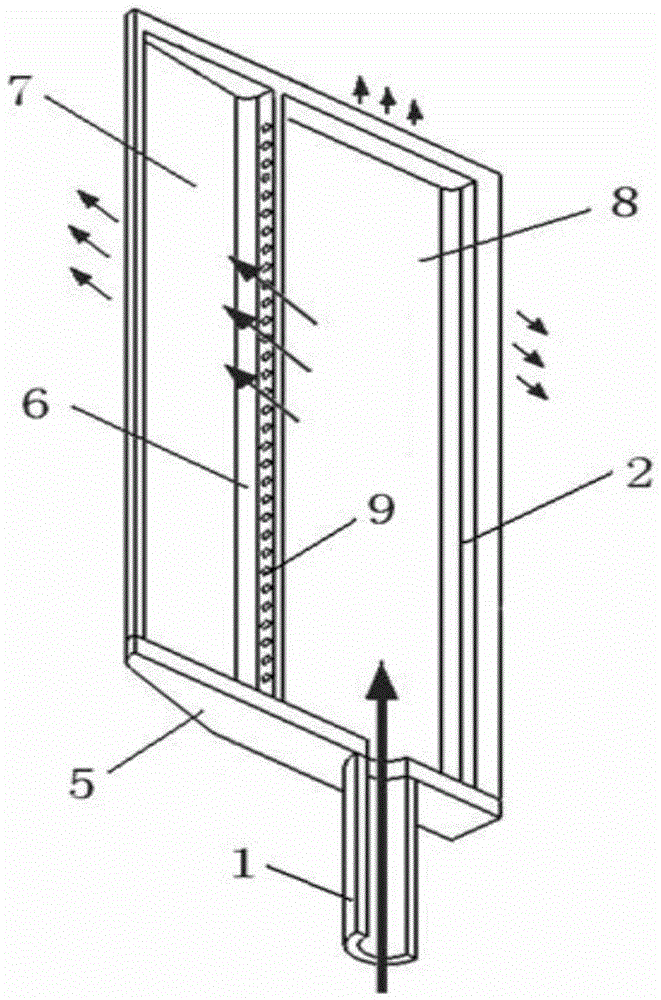

Thermal protection method for scramjet engine fuel injection supporting plate by utilization of transpiration cooling

ActiveCN103672966AReduce the temperatureAvoid ablative damageContinuous combustion chamberRamjetEngineering

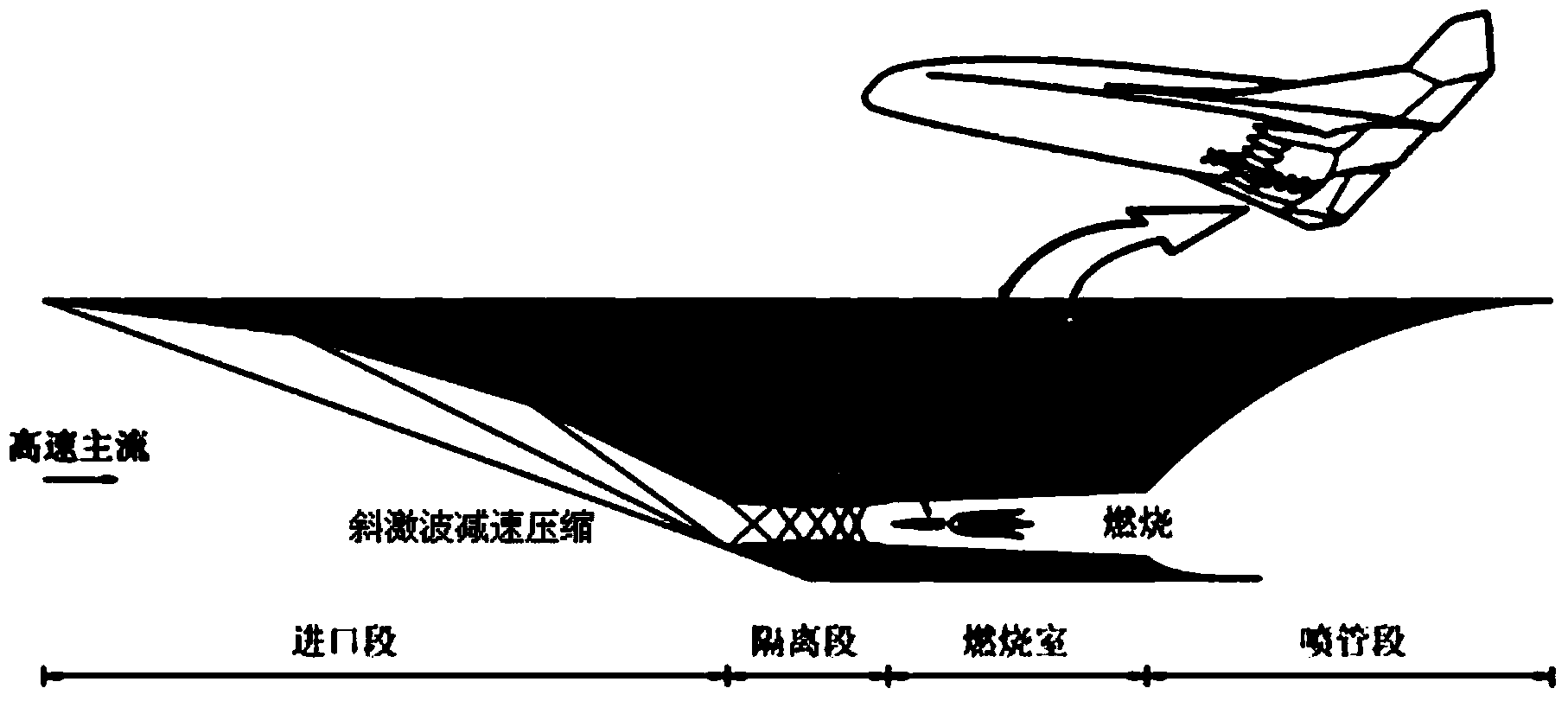

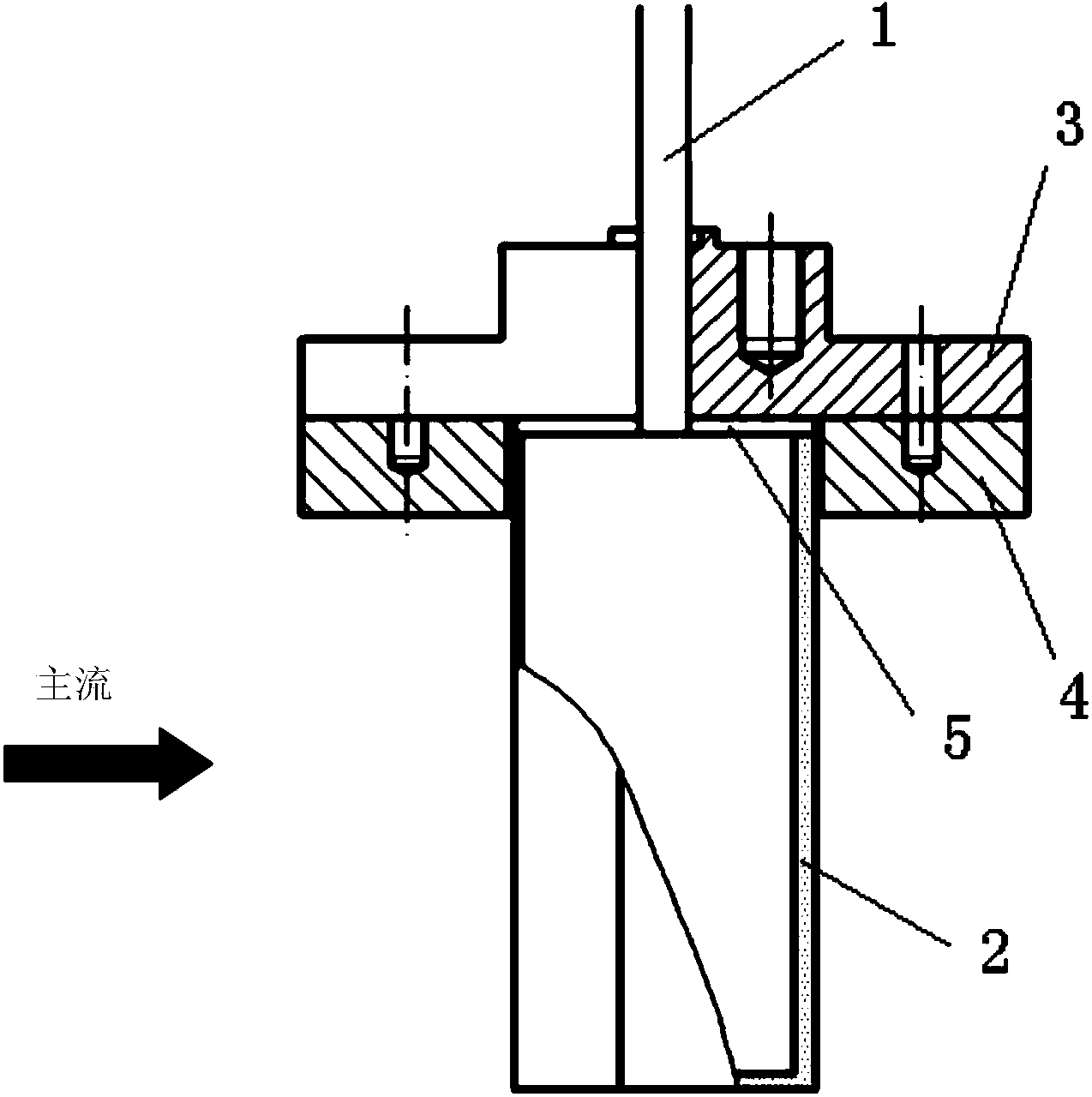

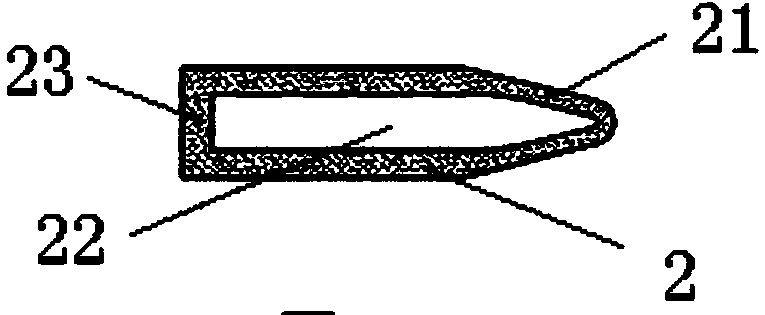

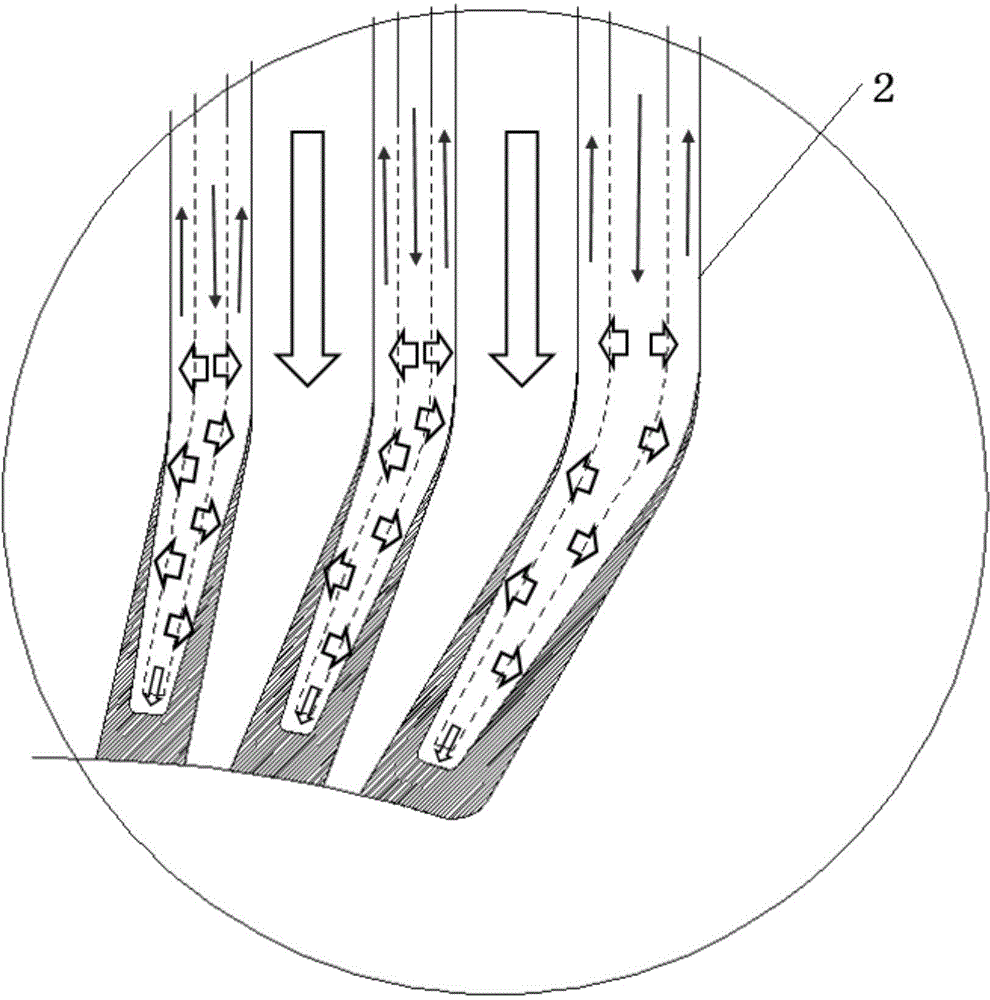

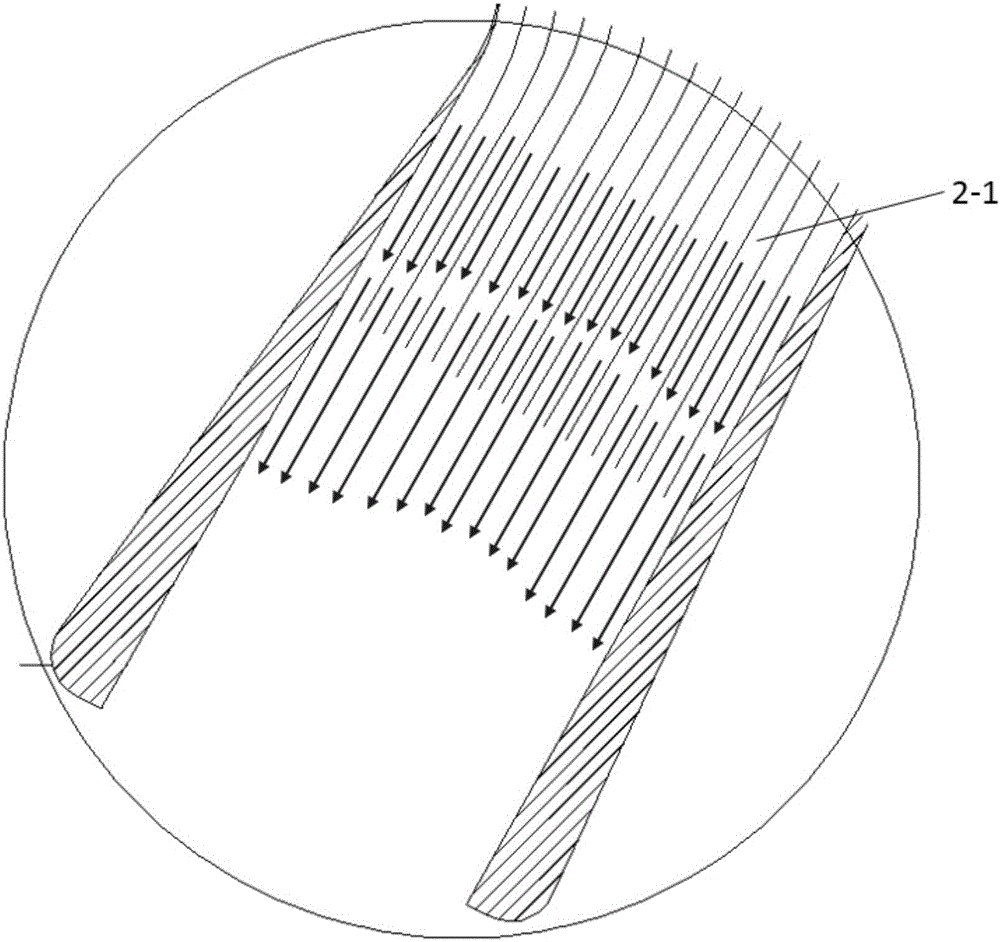

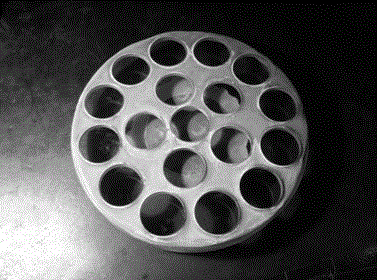

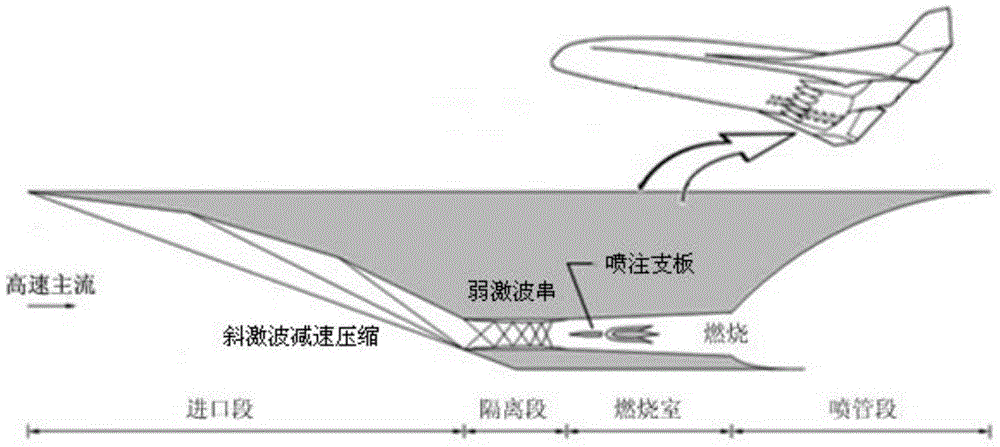

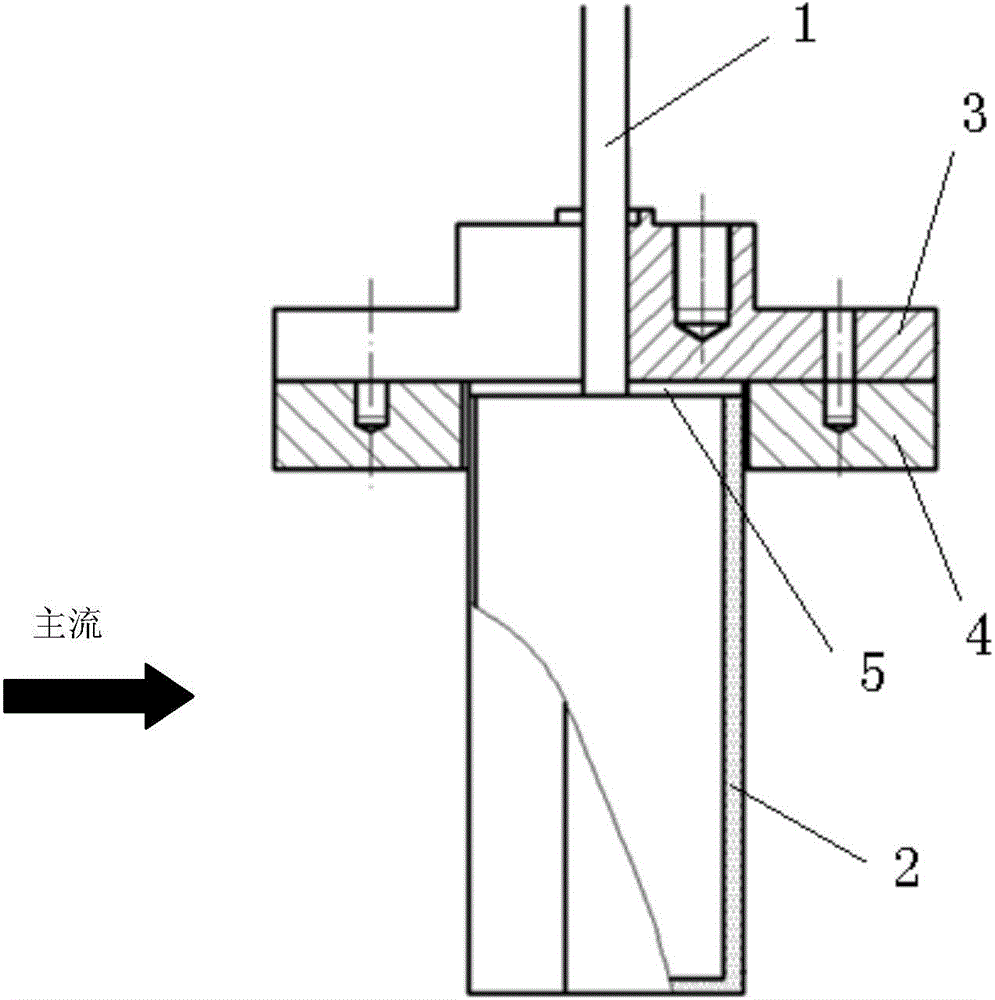

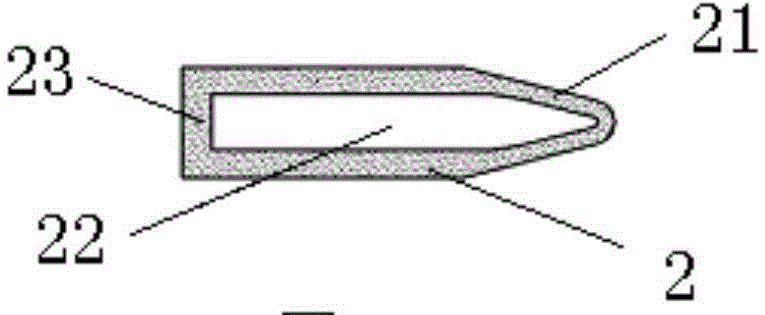

The invention relates to a thermal protection method for a scramjet engine fuel injection supporting plate by the utilization of transpiration cooling. The method includes the following steps that (1), high temperature resistant material is used for manufacturing the injection supporting plate of a multi-tiny-hole structure, and a fuel pipe of a scramjet engine is communicated with the injection supporting plate; (2), by the utilization of the process that fuel leaks through holes of the injection supporting plate of the multi-tiny-hole structure, and heat convection is performed forcibly, so that the heat on the surface of the injection supporting plate is taken away; (3), it is utilized that the fuel leaks through the surface of the injection supporting plate to form a thin layer, so that main flows are prevented from performing heat transfer on the injection supporting plate. The multi-tiny-hole structure is manufactured on the injection supporting plate material, the concept of transpiration cooling is used, the fuel serves as a cooling agent, so that strong heat convection happens between the fuel and the injection supporting plate in the process that the fuel flows through the injection supporting plate, meanwhile, the fuel forms the thin layer on the surface of the injection supporting plate, heat transfer between the high temperature main flows and the surface of the injection supporting plate is obstructed, thermal protection on the injection supporting plate and particularly the front edge part of the injection supporting plate is achieved, and the injection supporting plate is prevented from being ablated and damaged. The thermal protection method can be widely applied to thermal protection performed on various ramjet injection supporting plate structures.

Owner:TSINGHUA UNIV

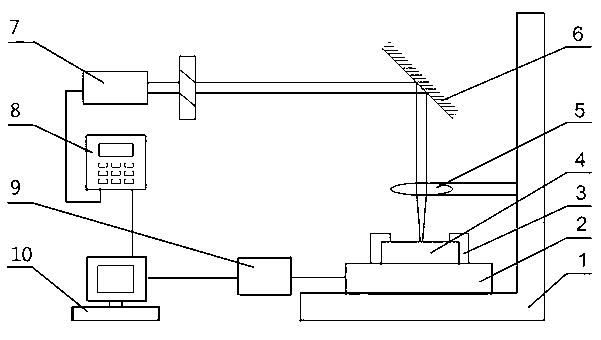

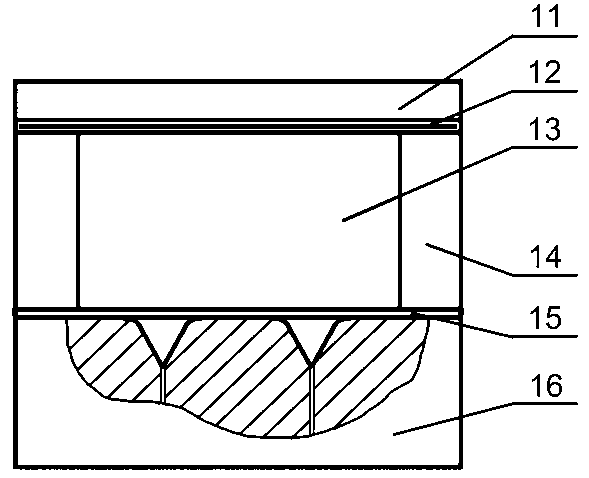

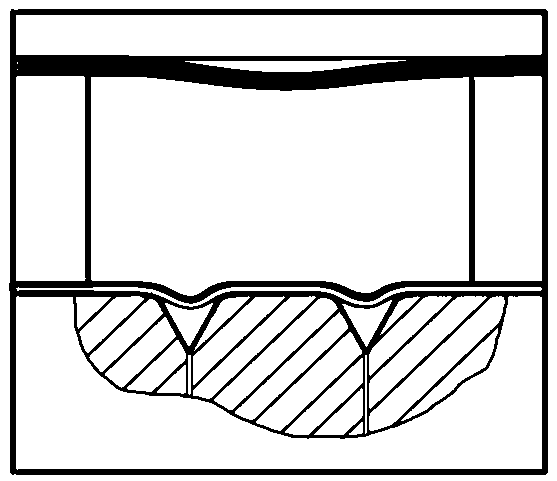

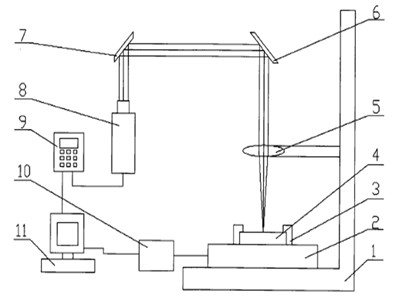

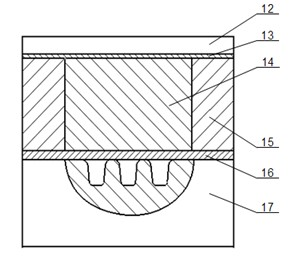

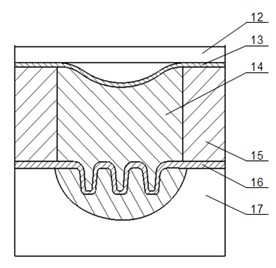

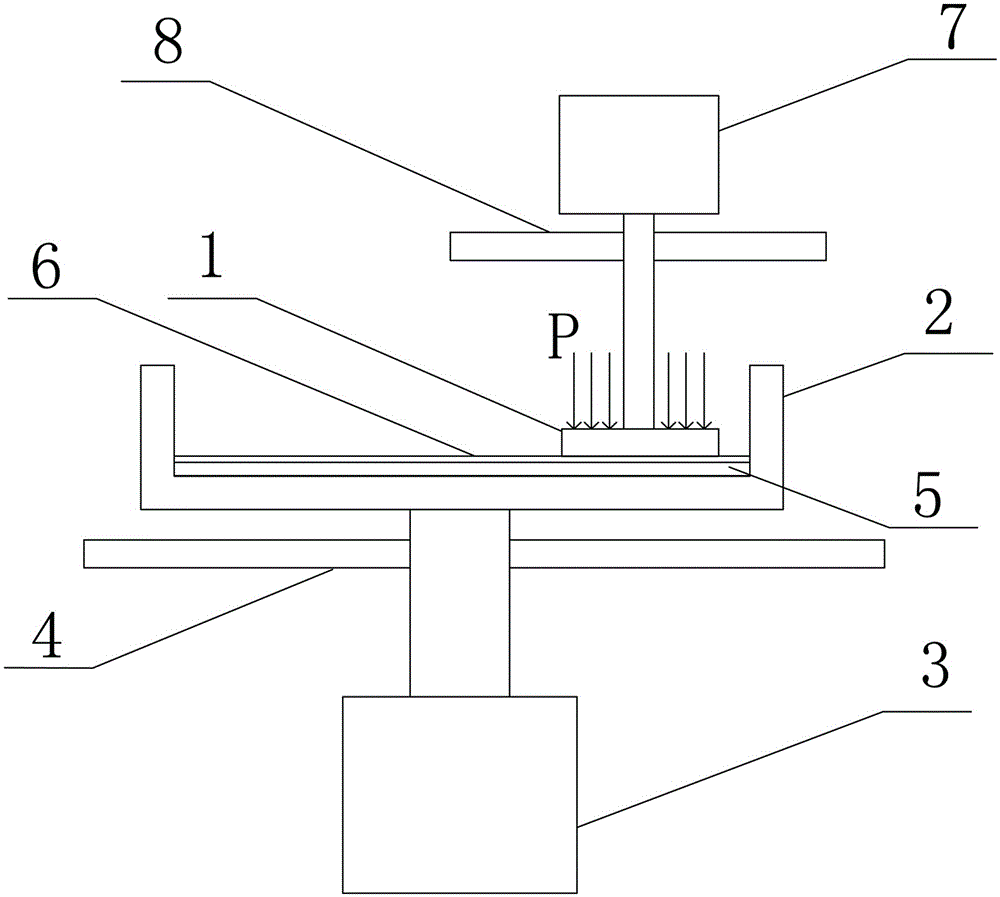

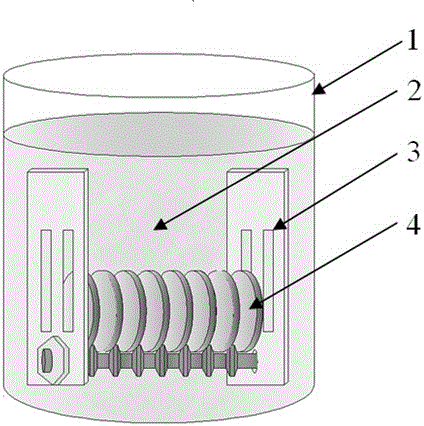

Precise micro-forming device and method thereof based on laser continuous stamping plasticine technology

InactiveCN103252588APrevent springbackEven by forceLaser beam welding apparatusComputer control systemNanosecond laser

The invention discloses a precise micro-forming device and a method thereof based on a laser continuous stamping plasticine technology. The device comprises a laser loading system, a plastic forming system and a computer control system. The laser loading system comprises a nanosecond laser, a reflection mirror and a focusing lens. The plastic forming system comprises a sample system, a clamp body, a three-dimensional moving platform and a base. The computer control system comprises a three-dimensional moving platform controller, a laser controller and a computer. According to the device and the method, plasticine is used for transmitting impact force, in a multi-time impact process, the plasticine and a workpiece are attached together gradually, stress on the workpiece is even, scratching cannot happen, surface quality of the workpiece is improved, and meanwhile according to the characteristic that the plasticine deforms in an plastic mode after being stressed, the workpiece and a micro mould can be attached with each other, rebounding of the workpiece is avoided, and forming precision of the workpiece is guaranteed.

Owner:JIANGSU UNIV

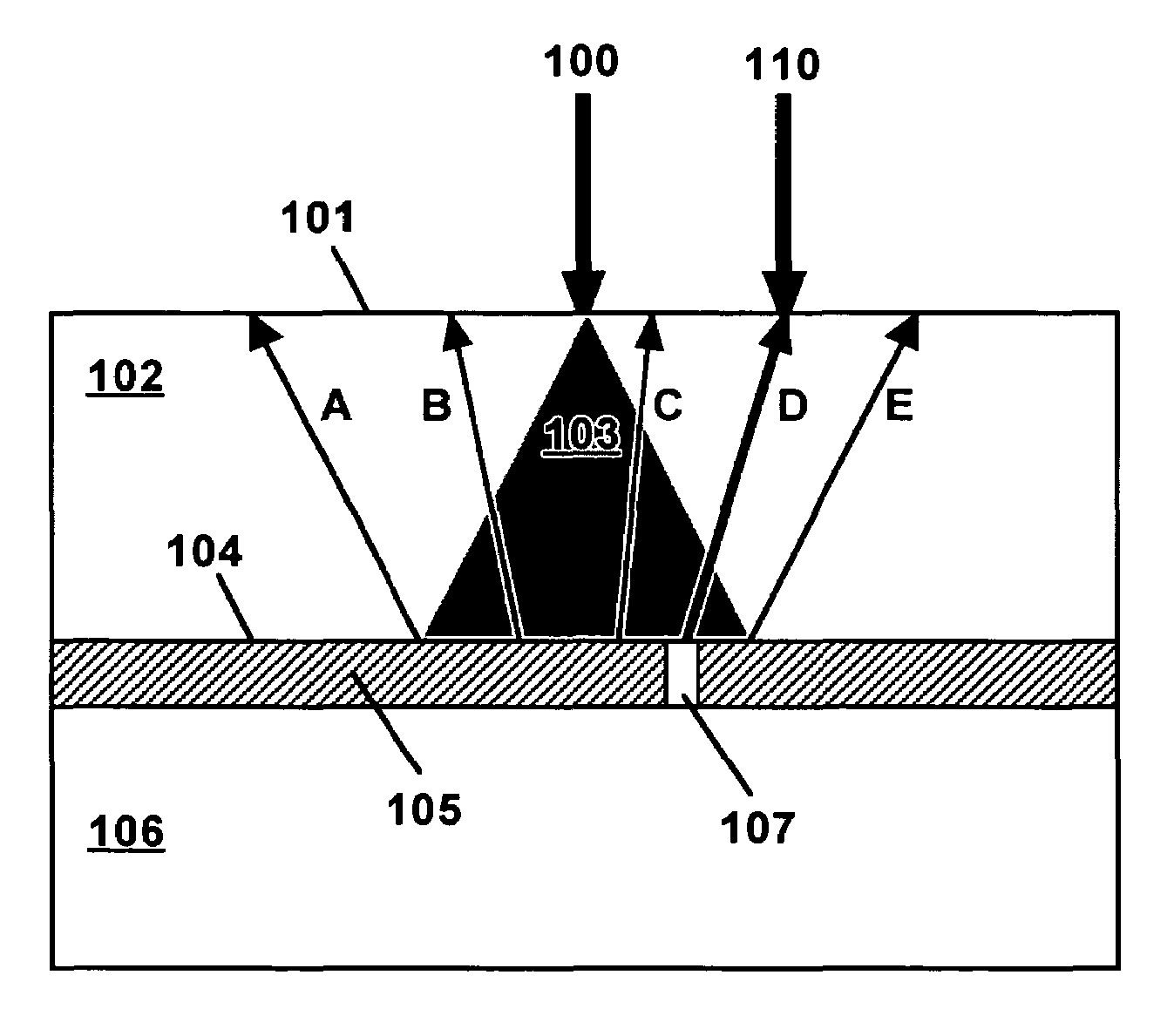

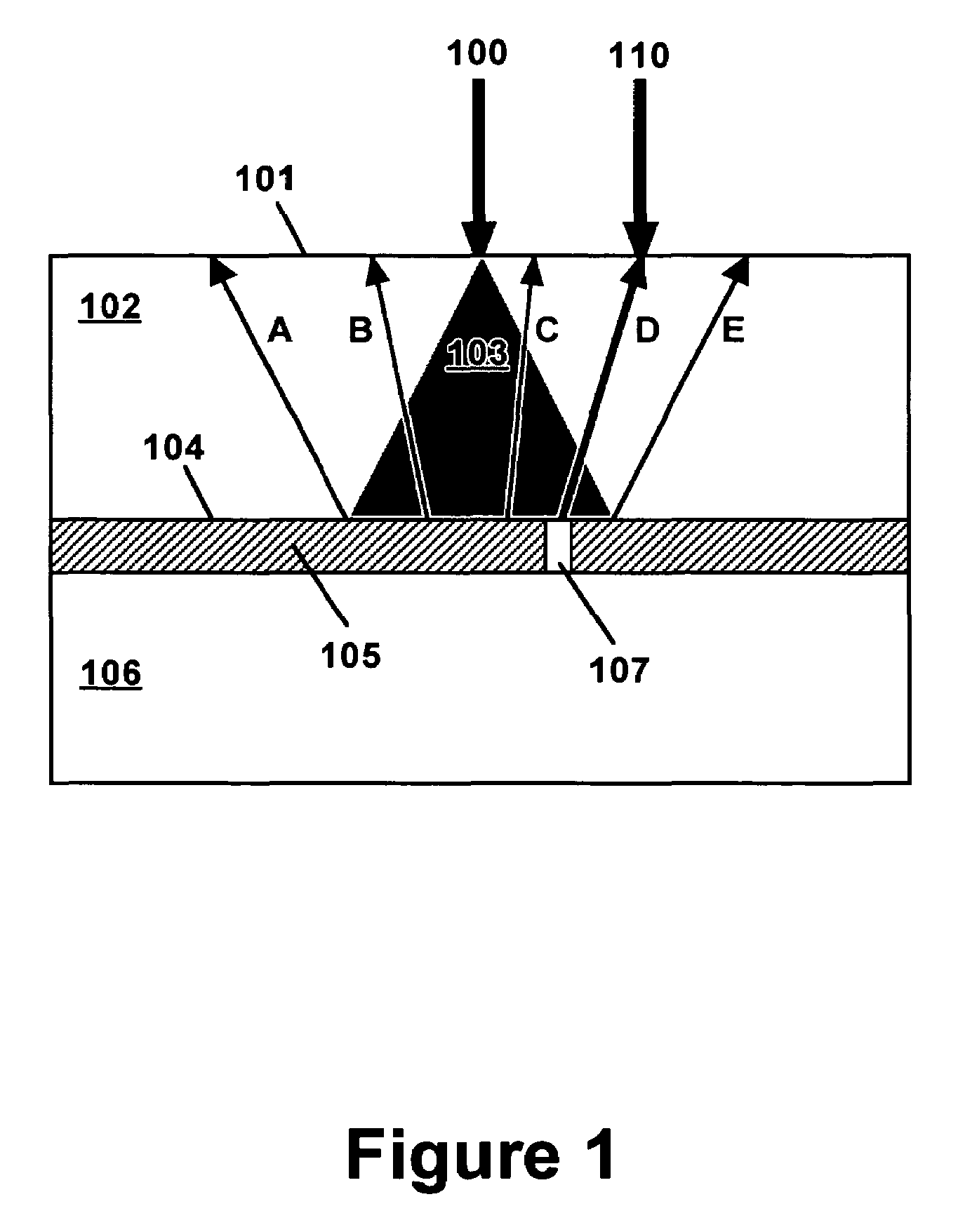

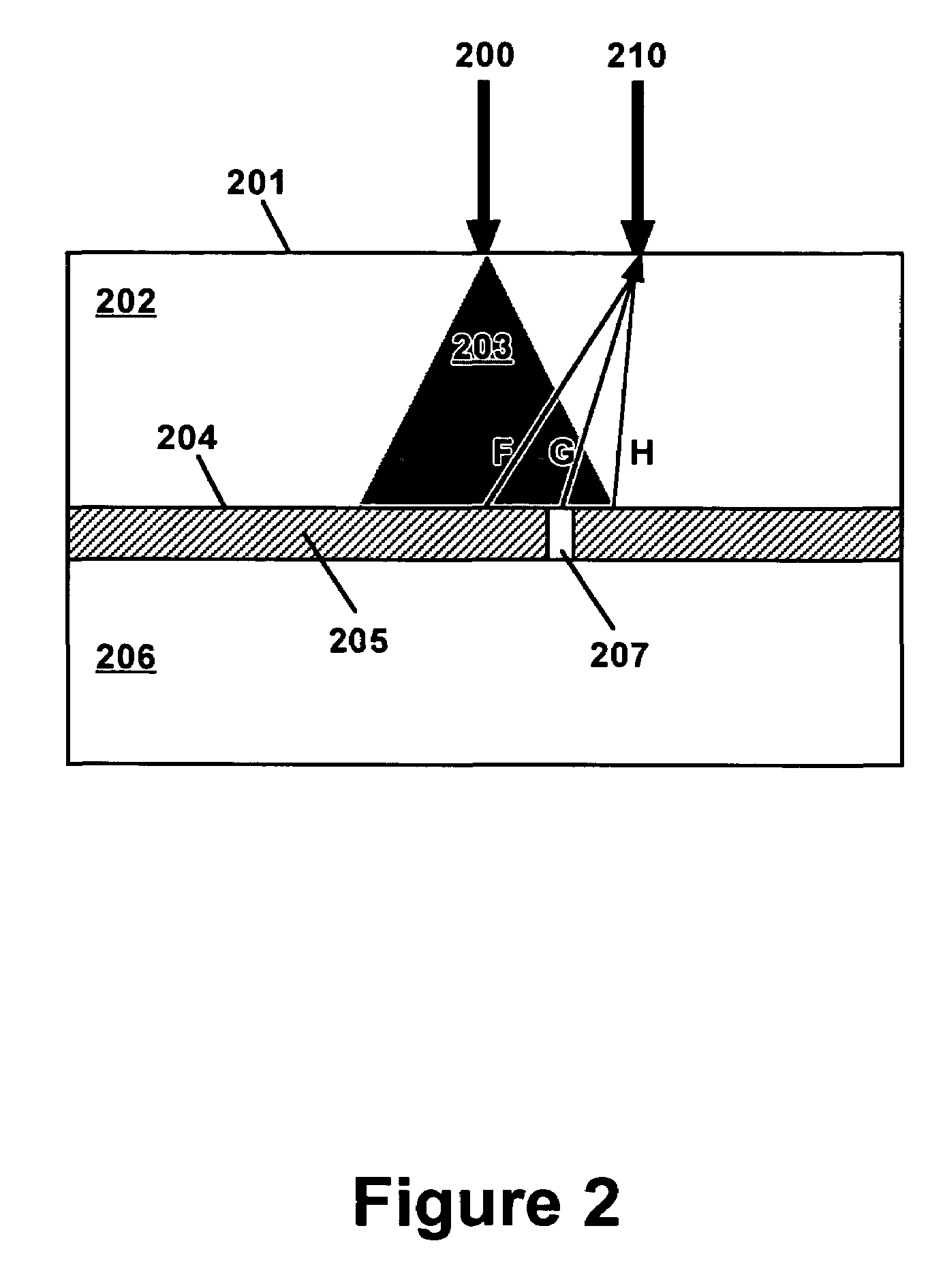

Laser-ultrasonic detection of flip chip attachment defects

InactiveUS7327448B2Improve directivityIncrease intensityVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesLaser detectionLaser beams

Owner:OPTECH VENTURES +1

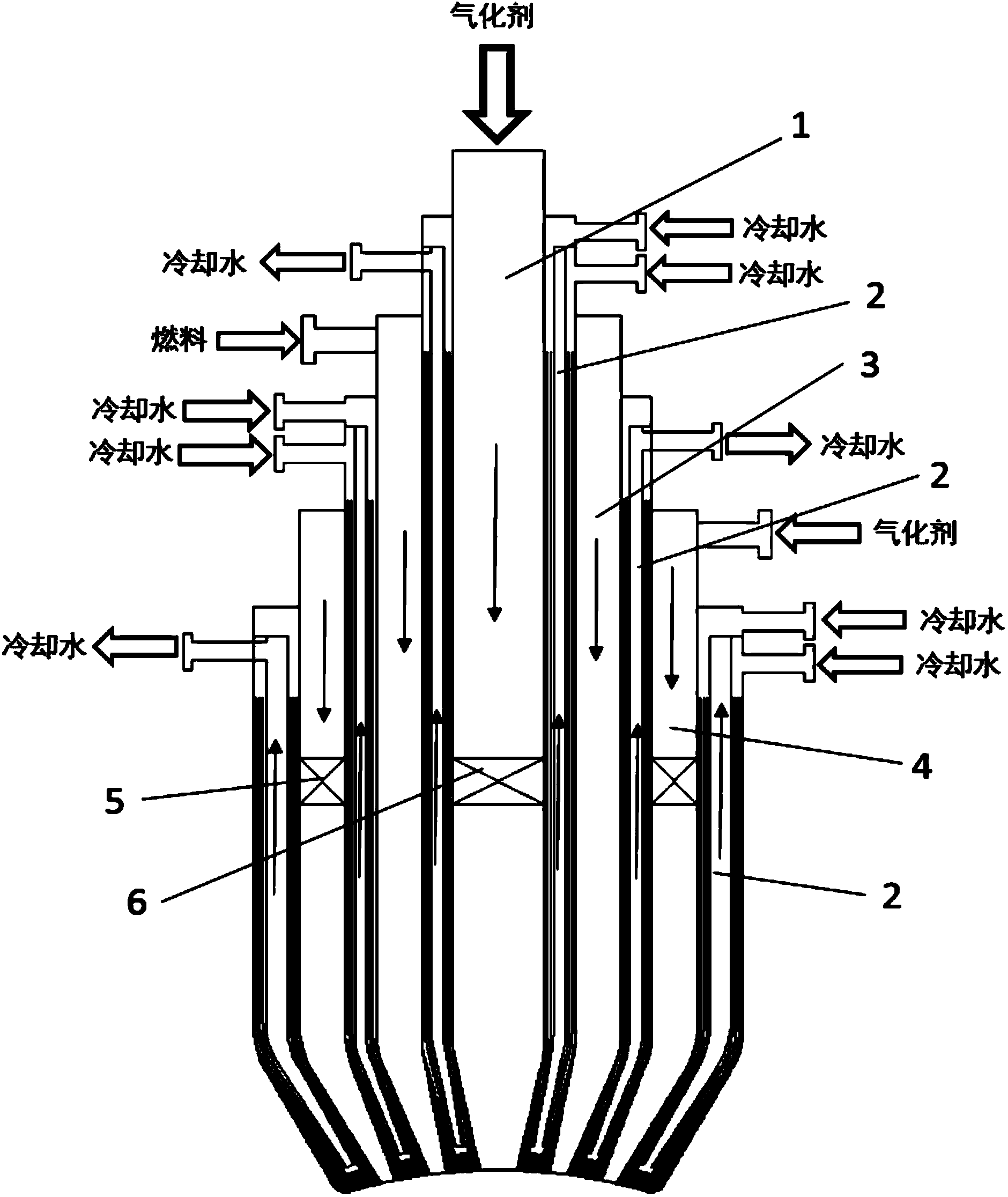

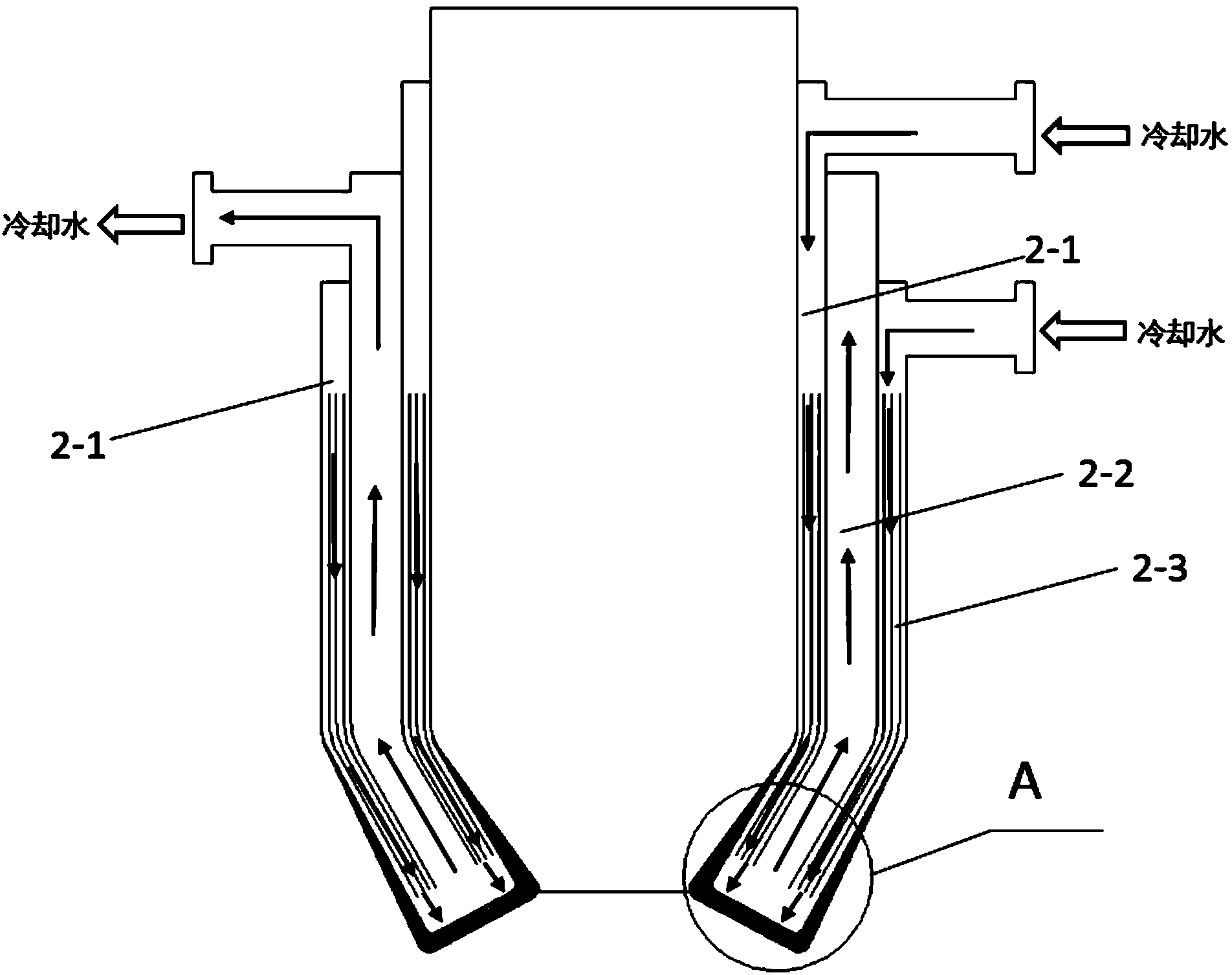

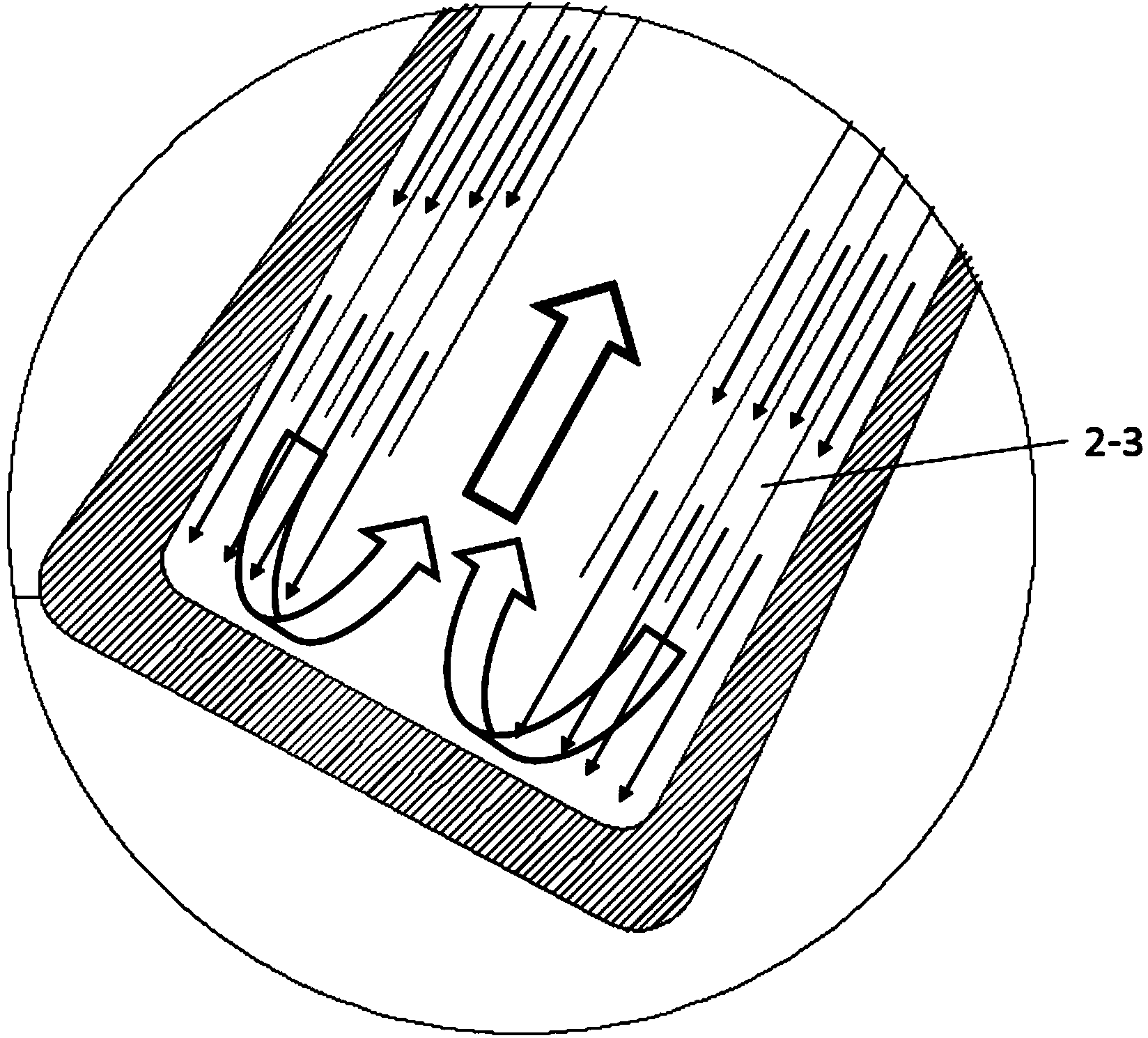

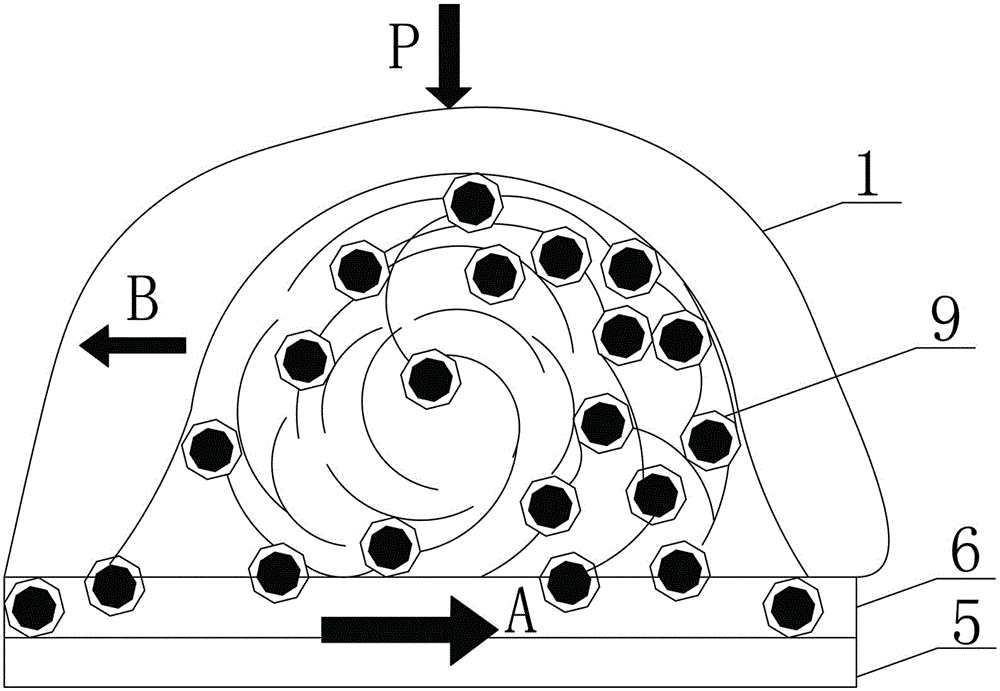

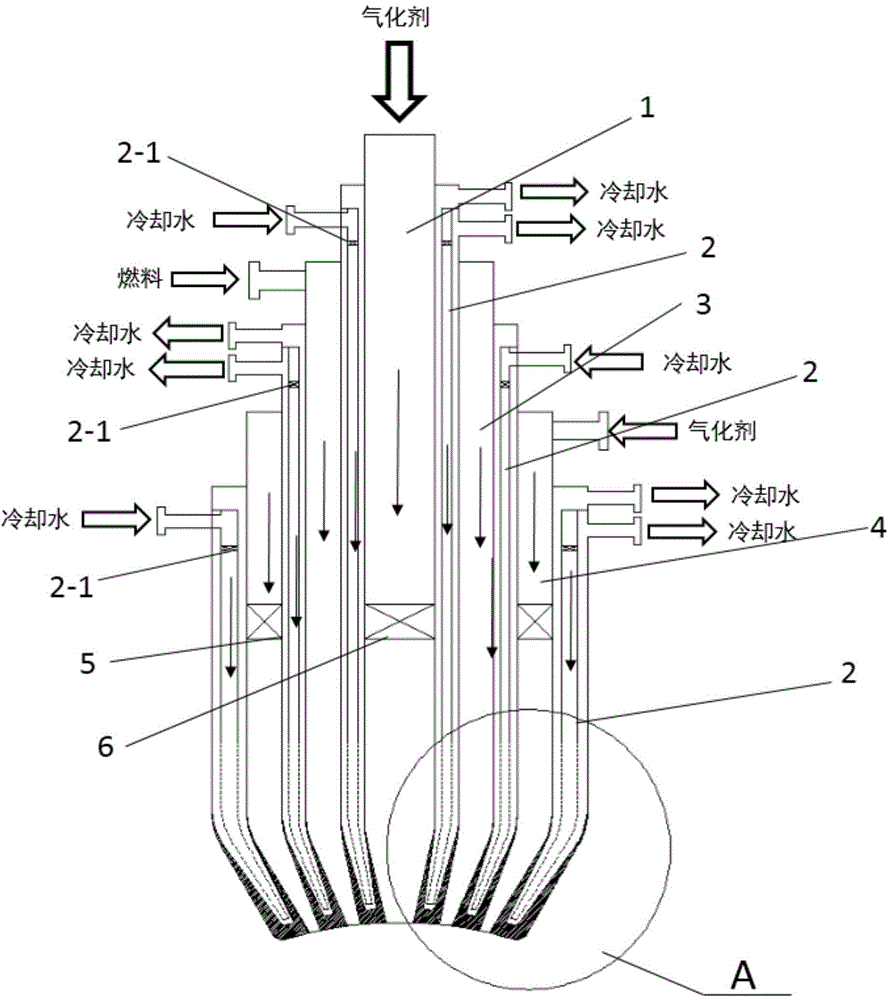

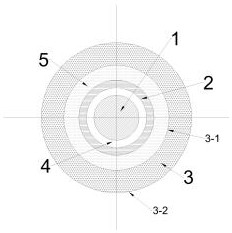

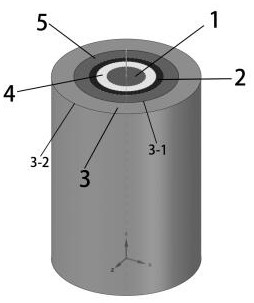

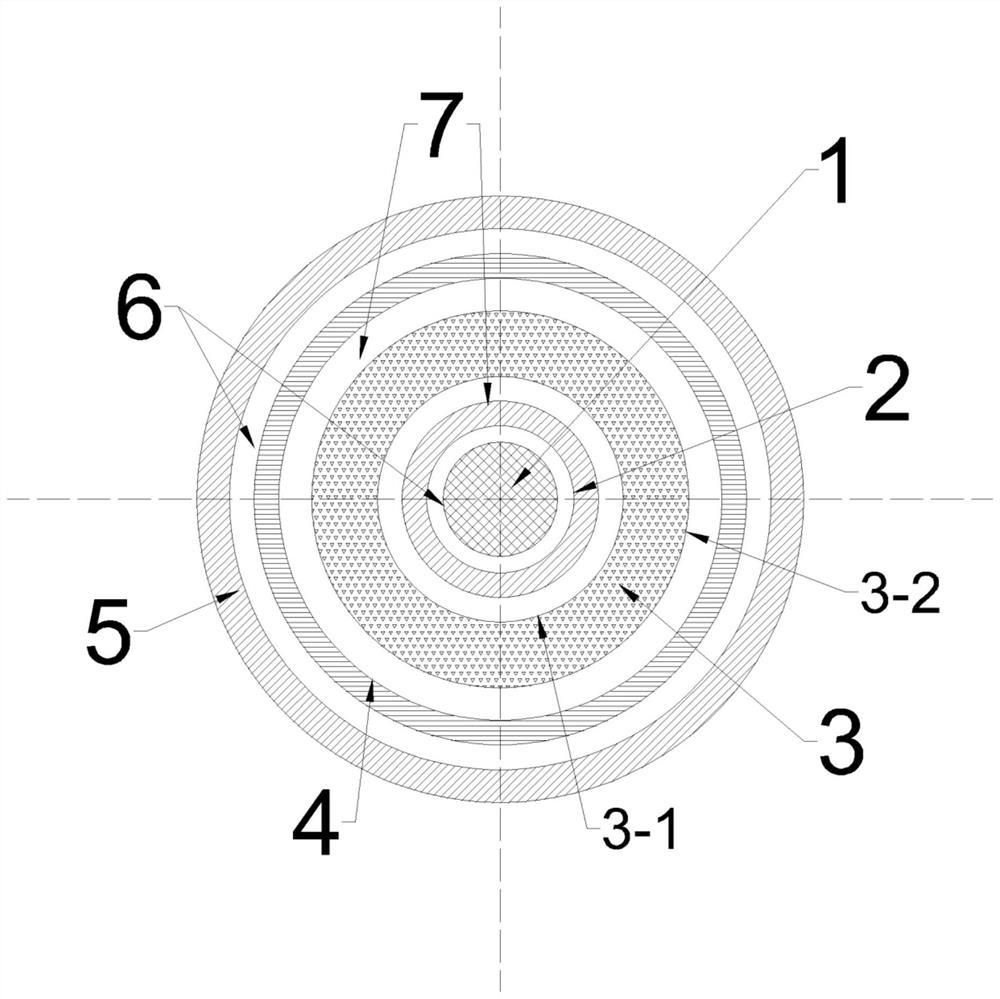

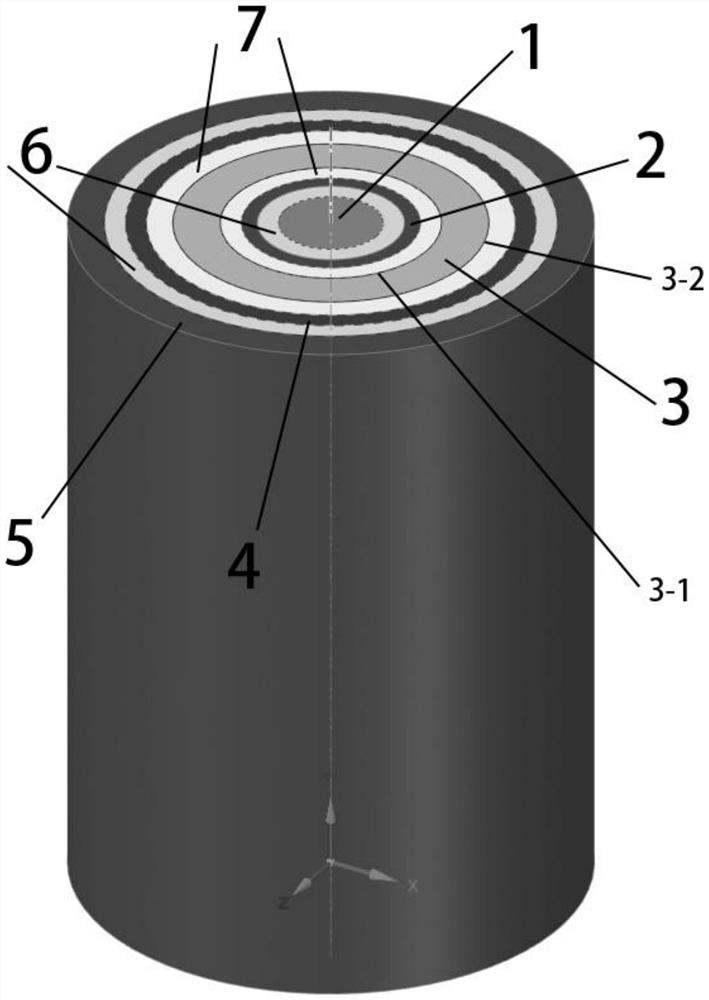

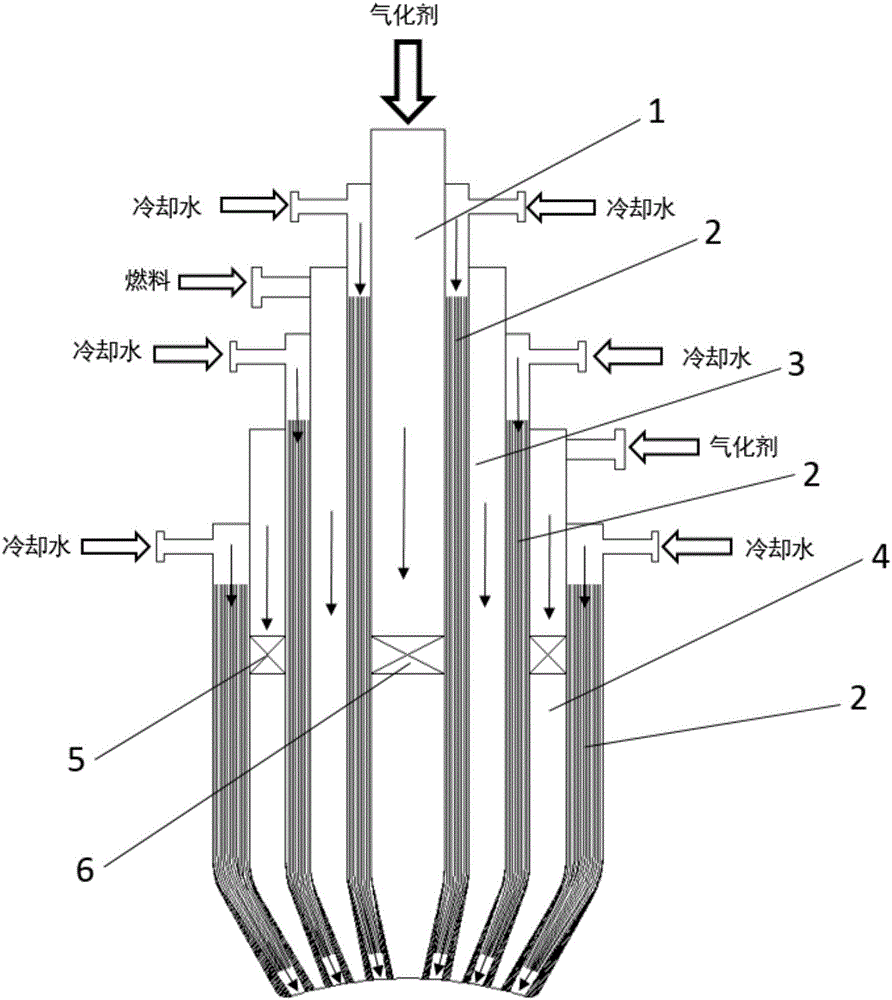

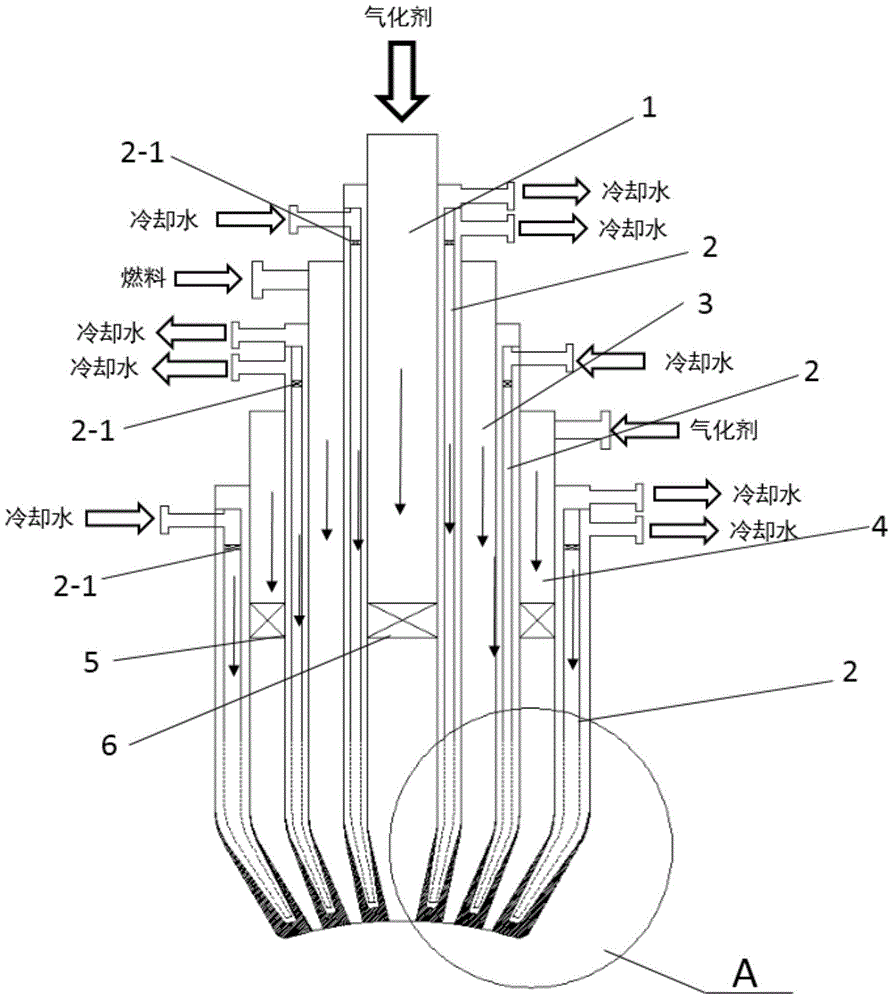

Novel micro-channel circularly cooling gasification process nozzle

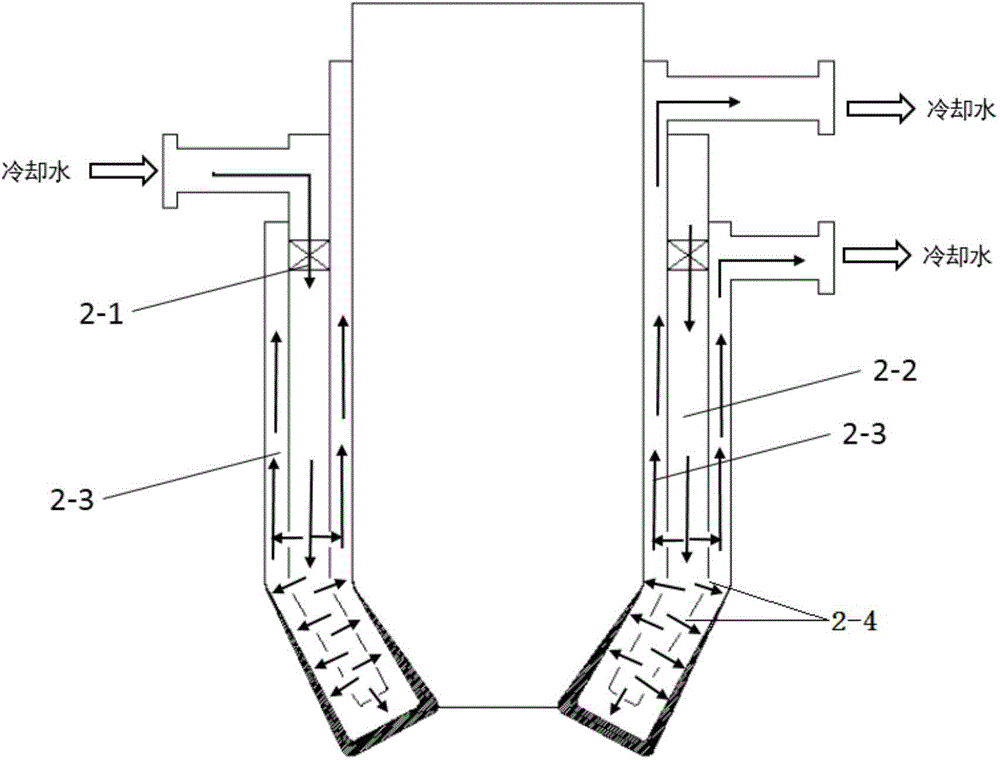

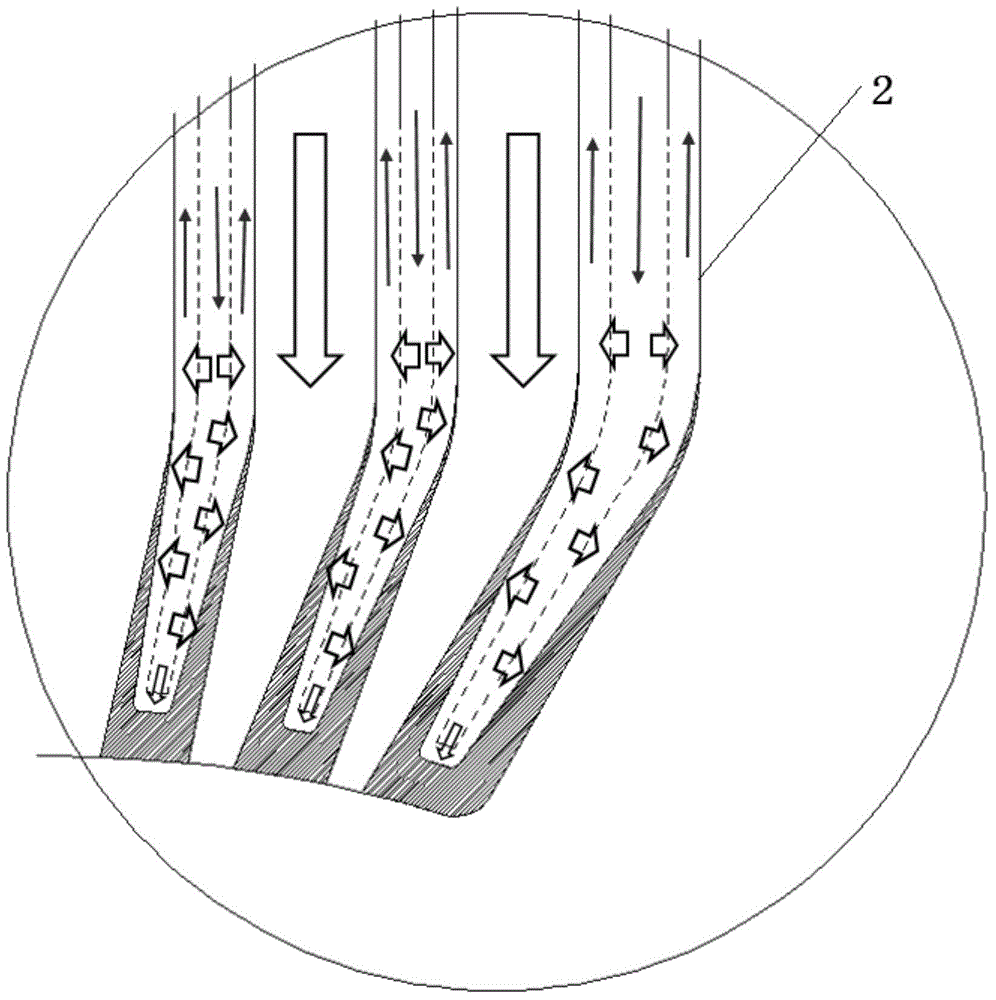

ActiveCN103881760AGuaranteed uptimeExtended service lifeGranular/pulverulent flues gasificationWater channelWater flow

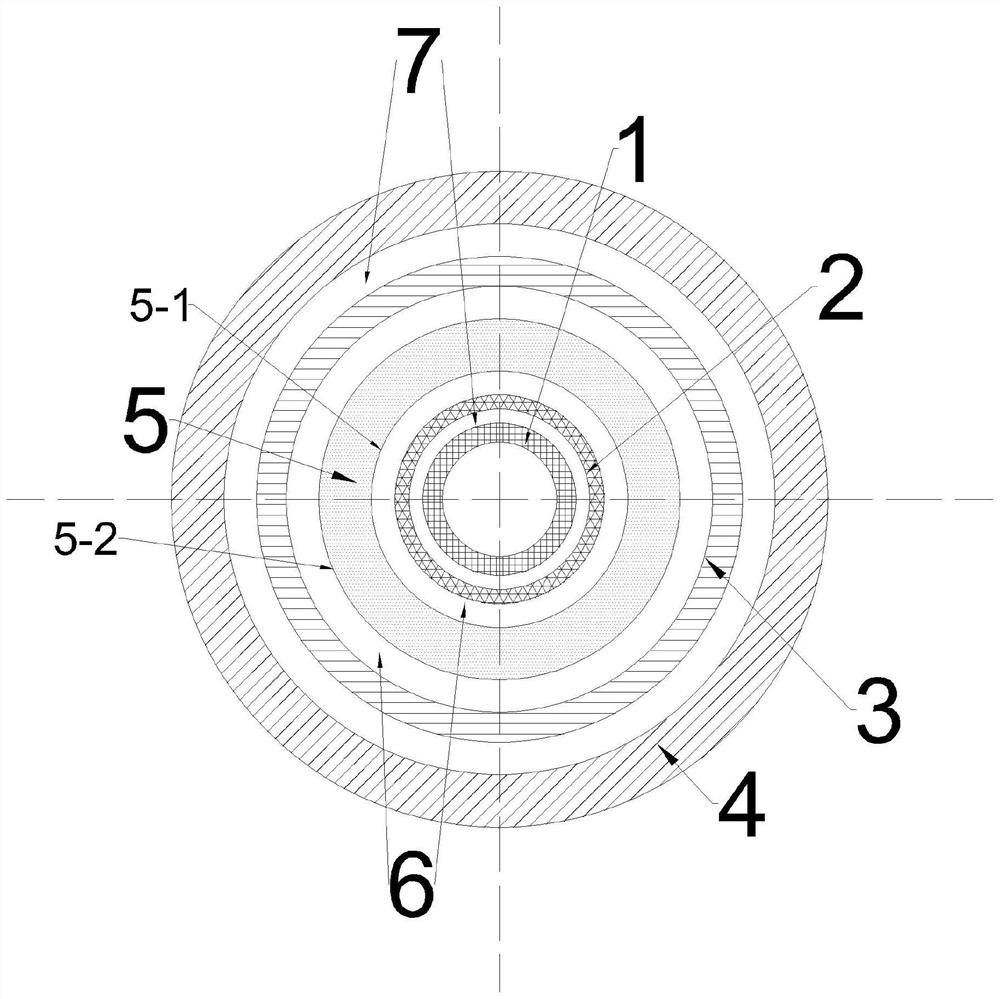

The invention provides a novel micro-channel circularly cooling gasification process nozzle. The nozzle comprises a center gasifying agent channel, a fuel channel, an outer gasifying agent channel and cooling water channels which are distributed between the center gasifying agent channel and the fuel channel, between the fuel channel and the outer gasifying agent channel and outside the gasifying agent channel, wherein the fuel channel and the outer gasifying agent are coaxial with and sequentially sleeved on the center gasifying agent channel; the water intake channels of the cooling water channels are composed of a plurality of micro-channels; the flowing speed of high-pressure cooling water increases in the micro-channels, and the center gasifying agent channel, the fuel channel, the outer gasifying agent channel and metal wall surfaces of the cooling water channels are efficiently cooled in heat conduction and forced-convection heat transfer modes; cooling water is sprayed from the micro-channel outlets in a high-speed jet manner, and the bottom metal wall surfaces of the cooling water channels are effectively cooled in a forced impact jet convection heat transfer manner, and then the cooling water flows back to the water outlets of the cooling water channels from a return channel. The novel micro-channel circularly cooling gasification process nozzle can be used for overcoming the defect of the gasified nozzle technology in the prior artthe nozzle is poor in cooling effect and has a short service life.

Owner:XI AN JIAOTONG UNIV

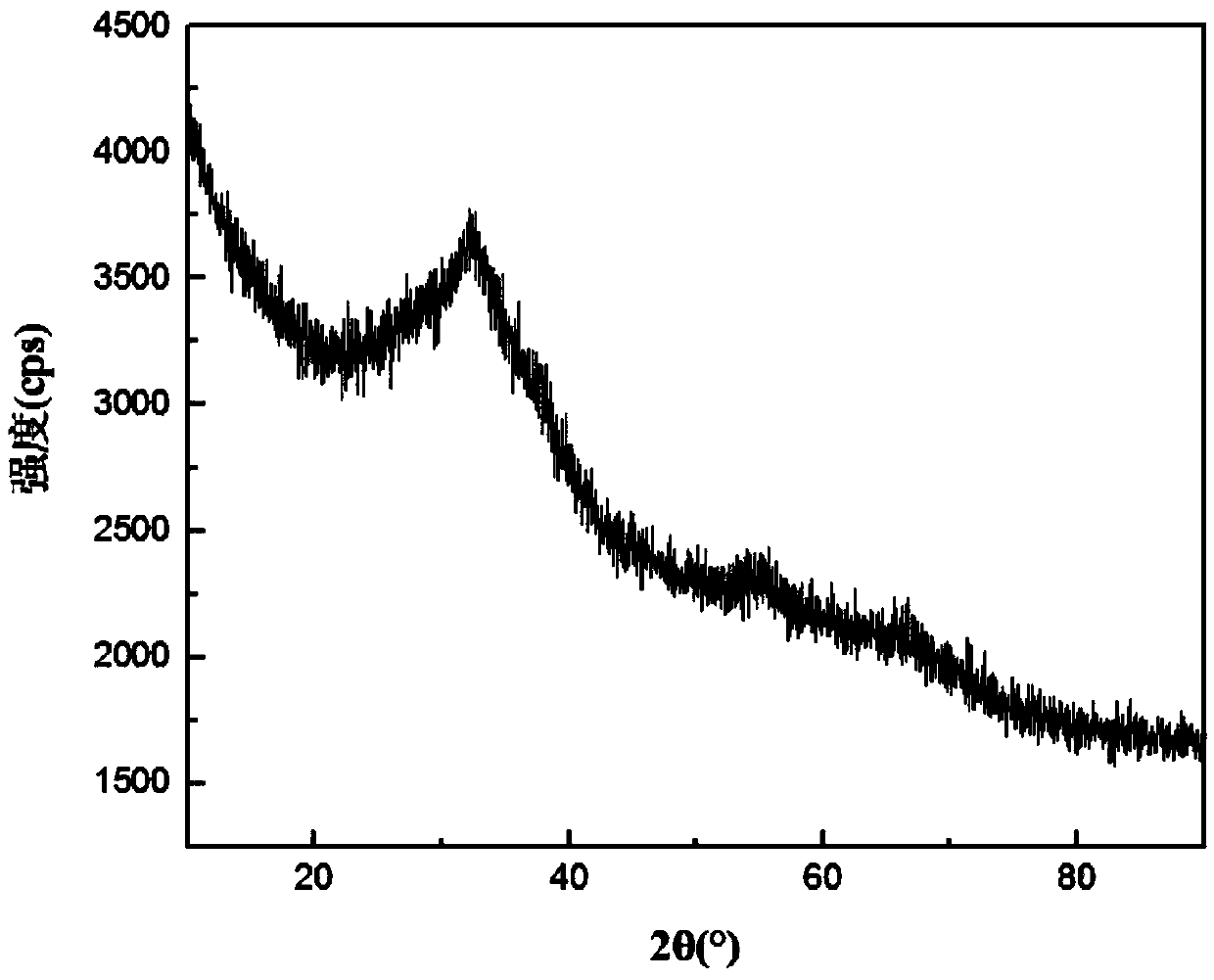

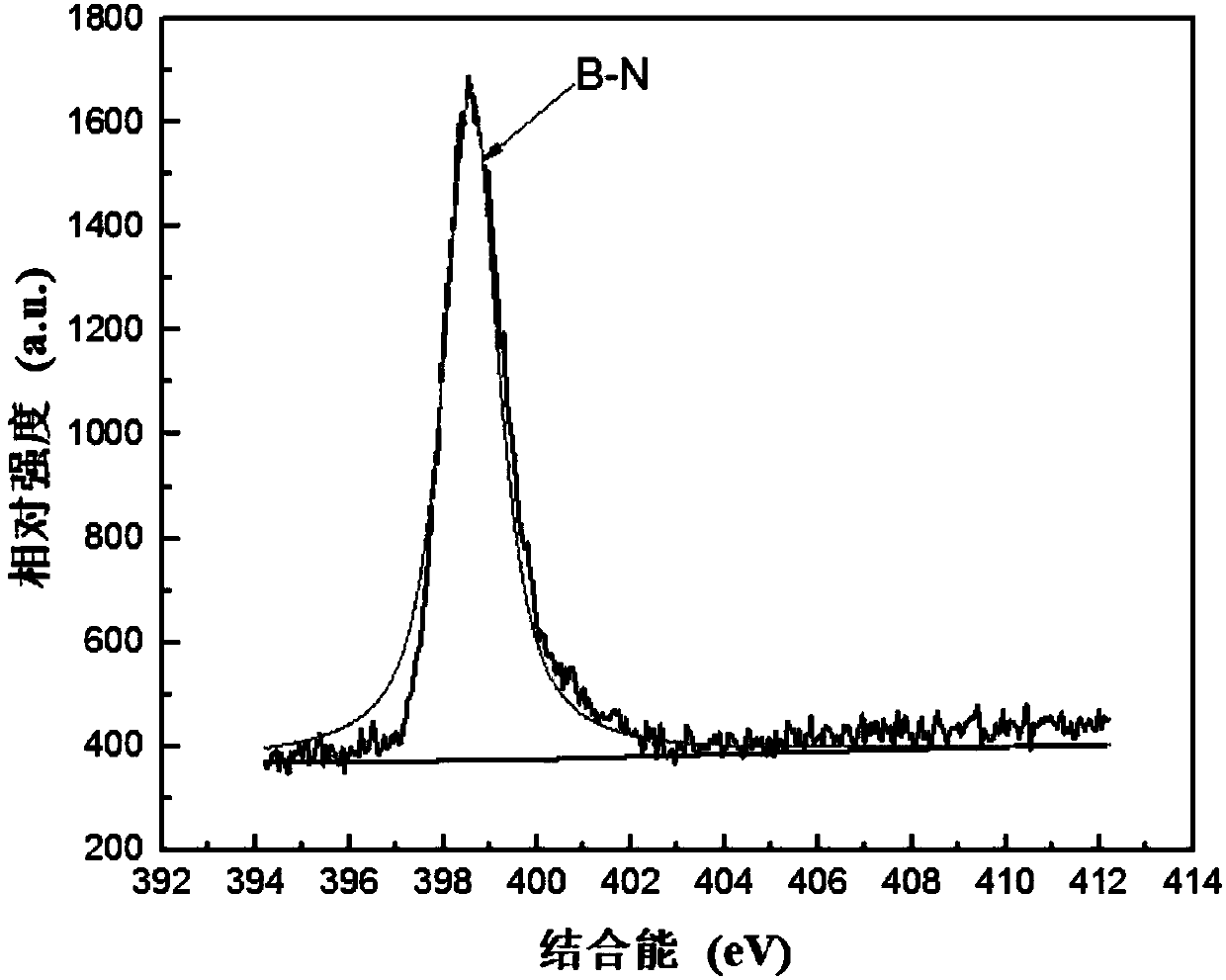

Ablation-resistant fiber toughened Si-B-C-N-Zr ceramic matrix composite as well as preparation method and application thereof

The invention discloses an ablation-resistant fiber toughened Si-B-C-N-Zr ceramic matrix composite as well as a preparation method and an application thereof. The preparation method of the ablation-resistant fiber toughened Si-B-C-N-Zr ceramic matrix composite comprises the following steps: S1, preparing Si-B-C-N-Zr powder; S2, performing surface modification treatment on fiber to obtain modifiedfiber; S3, mixing the modified fiber with the Si-B-C-N-Zr powder to obtain composite powder; S4, performing hot pressing and sintering on the composite powder to prepare the ablation-resistant fiber toughened Si-B-C-N-Zr ceramic matrix composite. The prepared ablative-resistant fiber toughened Si-B-C-N-Zr ceramic matrix composite has good microstructure and higher fracture toughness, mechanical property and ablative resistance, used raw materials are widely sourced and low in price, the preparation process is simple and mature, the preparation period is short, all the steps can be realized with existing technologies and equipment, and the composite is suitable for industrial production.

Owner:HARBIN INST OF TECH

Laser shock high molecular polymer indirect micro-forming method and dedicated device thereof

InactiveCN102513431AQuality improvementAvoid ablative damageLaser beam welding apparatusEtchingPhysical chemistry

The invention discloses a laser shock high molecular polymer indirect micro-forming method and a dedicated device thereof. A laser beam goes through an optical medium in a forming system and is exposed to an absorption coating film, so that a part of the absorption coating film is ablated to generate high-temperature high-pressure plasmas; the plasmas further absorb laser energy and then expand and explode; and the exploding plasmas expand towards the absorption coating film to generate a GPa-level impact pressure on the absorption coating film, resulting in plastic deformation of the absorption coating film. A high molecular polymer deforms towards a target work piece which is arranged at the lower part of the polymer under constraints of the impact pressure of the absorption coating film and the cavity of the high molecular polymer, resulting in plastic deformation of the target work piece. The method prevents ablative degradation or etching of the work piece surface and ensures precision forming of the work piece in the micro-mould.

Owner:JIANGSU UNIV

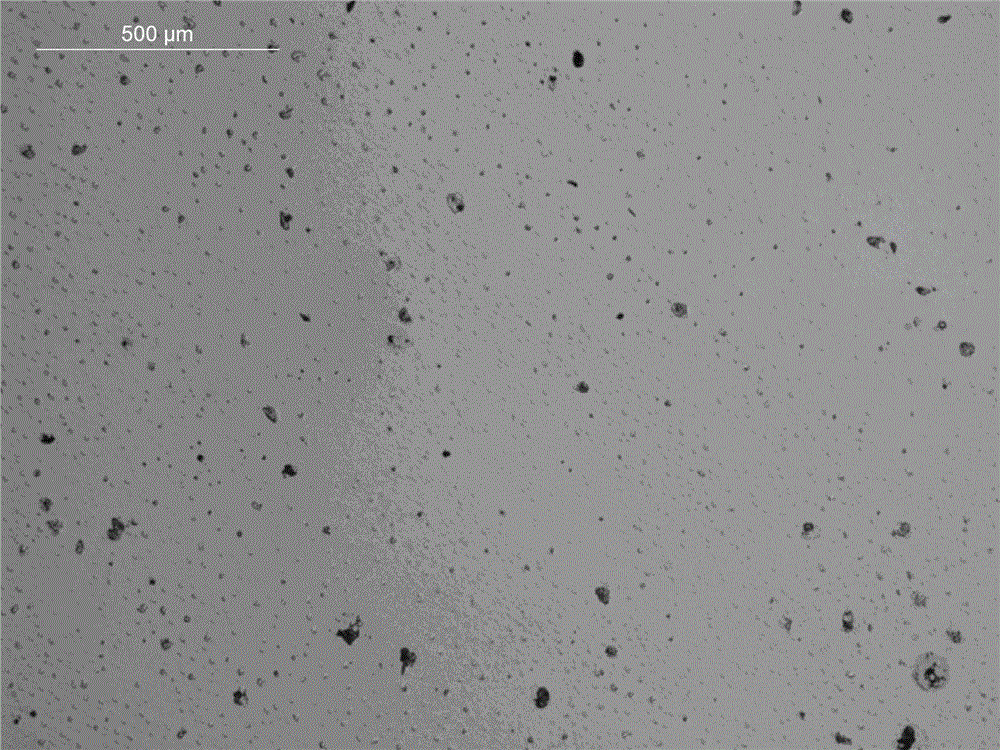

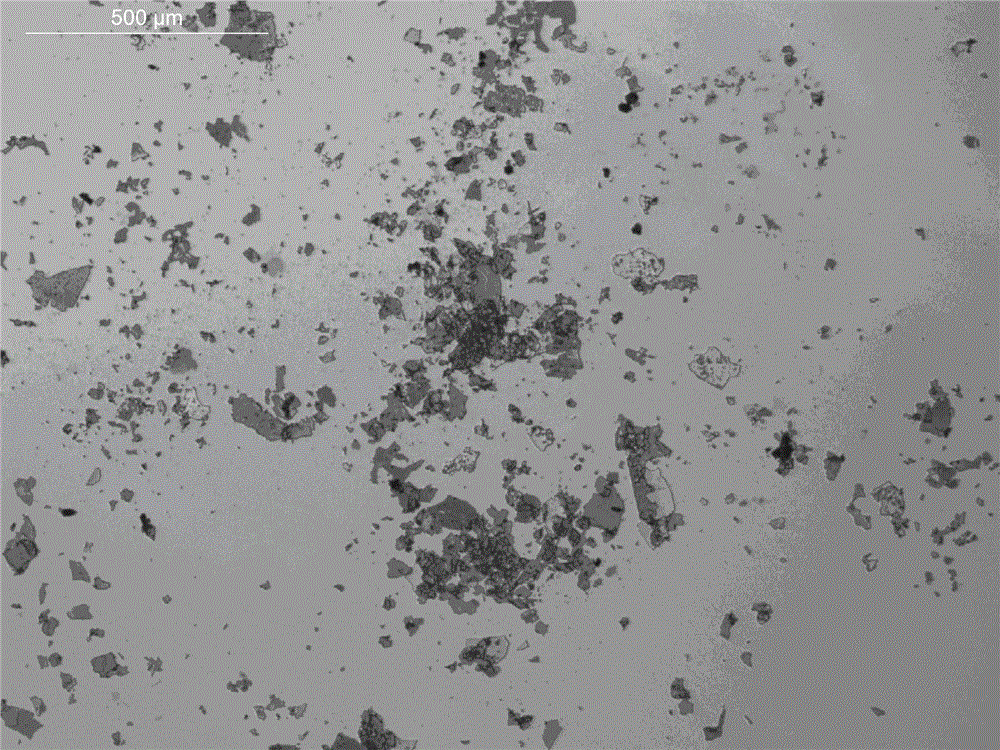

Forming method for metal surface micro-nano holes through mechanical lapping and lapping and polishing machine

ActiveCN105033838AShorten molding timeAvoid ablative damageLapping machinesMicro nanoStress concentration

The invention provides a forming method for metal surface micro-nano holes through mechanical lapping. The forming method comprises the steps that a lapping and polishing solution containing lapping particles and a metal workpiece with defects formed on the surface are provided; under the action of the lapping and polishing solution, mechanical lapping is carried out on the surface, with the defects, of the metal workpiece, the lapping and polishing solution is made to coerce the lapping particles to constantly carry out eddy lapping movement in the defects, lapping chips are generated by lapping the walls of the defects, the lapping particles and the lapping chips in the defects are flushed out constantly, and thus the micro-nano holes are formed in the defects. The invention further provides a lapping and polishing machine used in the forming method. Due to the fact that by means of the forming method, the micro-nano holes with the aperture capable of reaching the submicro dimension can be quickly formed in the defects, the forming time of the micro-nano holes is greatly shortened, the peripheries of the holes are in smooth transition, the phenomenon of stress concentration does not exist, the inner surfaces of the holes are regular and smooth, and the holes are hemispherical holes or cylindrical holes with the hemispherical bottoms.

Owner:ZHENGZHOU UNIV

Method for cleaning laser film

InactiveCN102873048AImprove cleaning efficiencyPrevent ablative damageCleaning using liquidsIonPhysics

The invention relates to a method for cleaning a laser film. The method specifically comprises the steps that a cotton swab dipped with acetone is used for slightly wiping the surface of the laser film, the wiped laser film is put in a first cleaning tank, alkaline solution is filled into the first cleaning tank to clean a sample, and the solution temperature is the room temperature; the volume ratio of the alkaline solution is that NH4OH: H2O2: H2O equals to 1: 10: 50; the obtained solution is respectively subjected to ultrasound for 2-4 minutes at the frequencies of 120 kilohertz-180 kilohertz and 200 kilohertz-300 kilohertz; the obtained sample is put in a second cleaning tank and is rinsed through deionized water, and the temperature of the deionized water is the room temperature; the sample is put in a third cleaning tank 3, the deionized water is added into the third cleaning tank, and the sample is respectively subjected to ultrasound for 3-6 minutes at the frequencies of 120 kilohertz-180 kilohertz and 200 kilohertz-300 kilohertz; and the sample is taken out, repeatedly cleaned and dried to obtains the required product. The method has the advantages that the high cleaning efficiency is realized, organic pollutants and contamination particles on the surface are effectively removed, meanwhile, the laser film cannot be physically damaged, the film is prevented from being eroded and damaged due to the particles which are absorbed to the surface of the film when the film is used in a high-power laser system, and the laser film is enabled to have high damage threshold when being used in the high-power laser system.

Owner:TONGJI UNIV

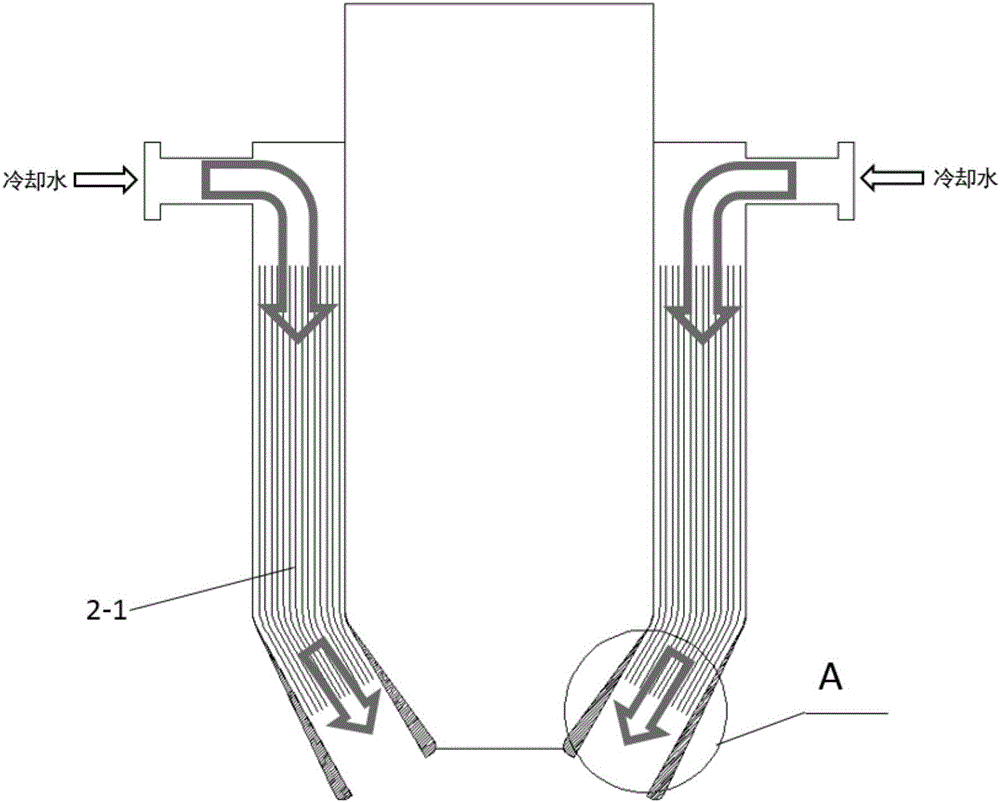

Novel jet impingement cooling gasification technology burner

ActiveCN103937553AGuaranteed uptimeExtended service lifeGranular/pulverulent flues gasificationJet flowInlet channel

The invention discloses a novel jet impingement cooling gasification technology burner. The novel jet impingement cooling gasification technology burner comprises a central gasifying agent channel, fuel channels, outer gasifying agent channels, and cooling water channels; the central gasifying agent channel is coaxially sieved by the fuel channels and the outer gasifying agent channels successively; the cooling water channels are arranged between the central gasifying agent channel and the fuel channels, between the fuel channels and the outer gasifying agent channels, and on the outsides of the outer gasifying agent channels; the cooling water channels are composed of water inlet channels and water return channels; cooling water uniform distribution devices are arranged in the water inlet channels; the water inlet channels and the water return channels are communicated via a plurality of circular holes which are closely arranged on the lower channel parts of the water inlet channels; high pressure cooling water is delivered into the water inlet channels, and then the walls of the water return channels are impinged by the high pressure cooling water through the plurality of circular holes which are closely arranged on the lower channel parts of the water inlet channels in a jet flow manner, so that high efficient cooling of the walls of the water return channels is realized; and then the high pressure cooling water is delivered to water outlets of the cooling water channels via the water return channels. The novel jet impingement cooling gasification technology burner is capable of solving problems of existing gasification technology burners that cooling effect is poor, and service life is relatively short.

Owner:XI AN JIAOTONG UNIV

Method for preparing explosive composite rod based on water pressure in local vacuum environment

InactiveCN113560710AReduce bond strengthAvoid meltingNon-electric welding apparatusDetonatorExplosive Agents

The invention provides a method for preparing an explosive composite rod based on water pressure in a local vacuum environment. The method comprises the steps that a to-be-composited rod, a to-be-composited pipe, a small-size pvc pipe and a large-size pvc pipe are coaxially arranged from inside to outside; the two ends of a gap between the to-be-composited rod and the to-be-composited pipe are sealed by sealing strips, vacuumizing is carried out, and a vacuum gap environment is constructed; space between the small-size pvc pipe and the large-size pvc pipe is filled with an explosive and a detonator to form an explosive device; space between the to-be-composited pipe and the explosive device is filled with water, and a water environment is constructed; and the explosive device is detonated to enable the to-be-composited pipe and the to-be-composited rod to be welded and combined, and the high-quality explosive composite rod is obtained. According to the method for preparing the explosive composite rod based on the water pressure in the local vacuum environment, the problem that high-quality machining of a thin-wall material cannot be achieved through a traditional method is effectively solved; and the phenomenon that large-area melting of the bonding interface of composite materials is caused by an air layer which is not emptied in a gap is eradicated, and size selection of to-be-composited materials is freer.

Owner:ANHUI UNIV OF SCI & TECH

Method for preparing high-efficiency explosion composite pipes and rods based on water pressure in local vacuum environment

PendingCN113618224AImprove energy utilizationAvoid ablative damageNon-electric welding apparatusWater environmentVacuum gap

The invention provides a method for preparing high-efficiency explosion composite pipes and rods based on water pressure in a local vacuum environment. The method comprises the following steps: coaxially arranging a to-be-composited rod 1, a to-be-composited pipe 2, small-size and large-size pvc pipes and to-be-composited pipes 4 and 5; enabling the position between the small-size pvc pipe and the large-size pvc pipe to be filled with explosives and detonators to form an explosive device; sealing and vacuumizing the two ends of gaps between the to-be-composited rod 1 and the to-be-composited pipe 2 and between the to-be-composited pipes 4 and 5 by using sealing strips to construct a vacuum gap environment; injecting water between the to-be-composited pipes and the explosive device to construct a water environment; and starting the explosive device to weld and combine the to-be-composited materials to obtain the explosion composite pipes and composite rods. According to the method for preparing the explosion composite pipes and rods, the phenomenon that a composite material bonding interface is melted in a large area due to an air layer which is not emptied in the gaps is avoided, the utilization rate of the explosives is increased, and the difficulty that a thin-wall material cannot be machined in a high-quality manner through a traditional method is effectively solved.

Owner:ANHUI UNIV OF SCI & TECH

A Gasification Process Burner with Narrow Channel Jet Cooling

ActiveCN103881758BGuaranteed uptimeExtended service lifeGranular/pulverulent flues gasificationCooling effectHigh pressure

The invention relates to a novel gasifying process nozzle with a function of spray cooling through narrow channels. The nozzle comprises a central gasifying agent channel, a fuel channel and an external gasifying agent channel which are coaxially and sequentially sleeved outside the central gasifying agent channel, and cooling water channels which are arranged between the central gasifying agent channel and the fuel channel, between the fuel channel of the external gasifying agent channel and outside the external gasifying agent channel, wherein each cooling water channel consists of a plurality of narrow channels. High pressure cooling water is increased in the narrow channels at a flow rate to enhance the cooling effect on the central gasifying agent channel, the fuel channel, the external gasifying agent channel and the metal wall of the water cooling channel by way of heat conduction and forced-convection heat transfer. High pressure cooling water is sprayed from the outlets of the narrow channels in form of high speed impact jet to spray and cool the outlets of the nozzle so as to effectively cool the outlets of the nozzle by way of forced-convection heat transfer and phase-change heat transfer. The nozzle provided by the invention overcomes the defect that a nozzle in the gasifying nozzle technology in the prior art is poor in cooling effect and short in service life.

Owner:XI AN JIAOTONG UNIV

A cleaning method after precision polishing of optical components

InactiveCN105251745BGood removal effectHigh clean surfaceFlexible article cleaningCleaning using liquidsCleaning methodsEngineering

Owner:TONGJI UNIV

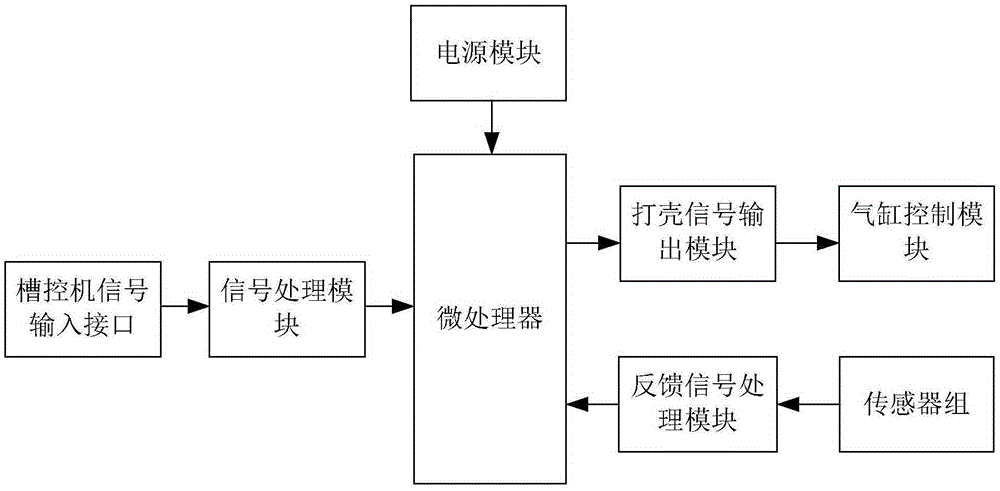

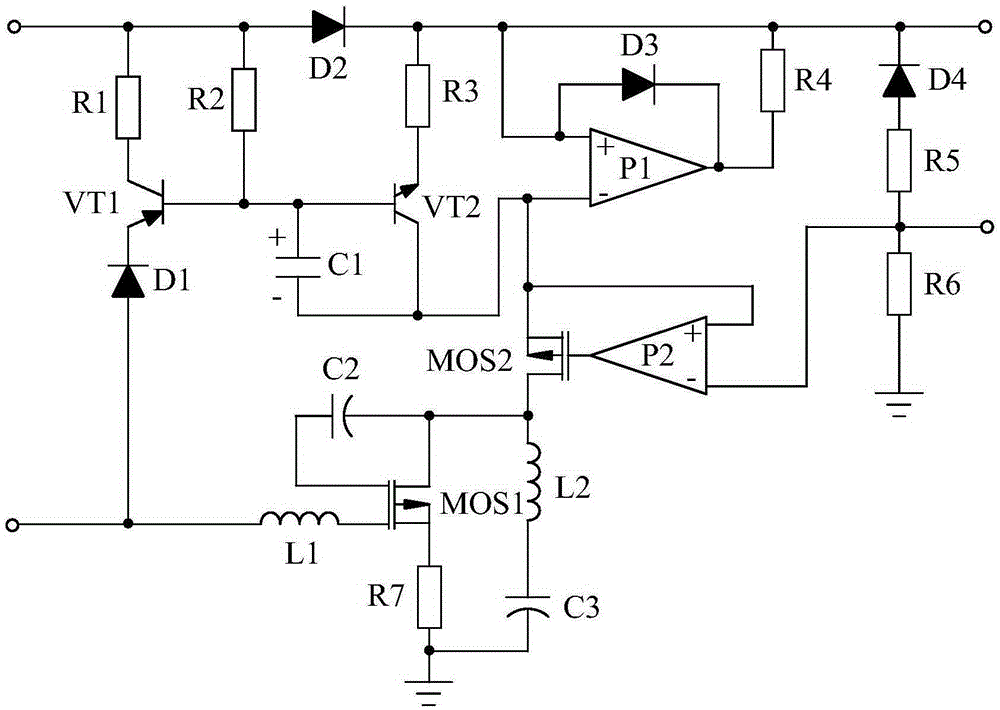

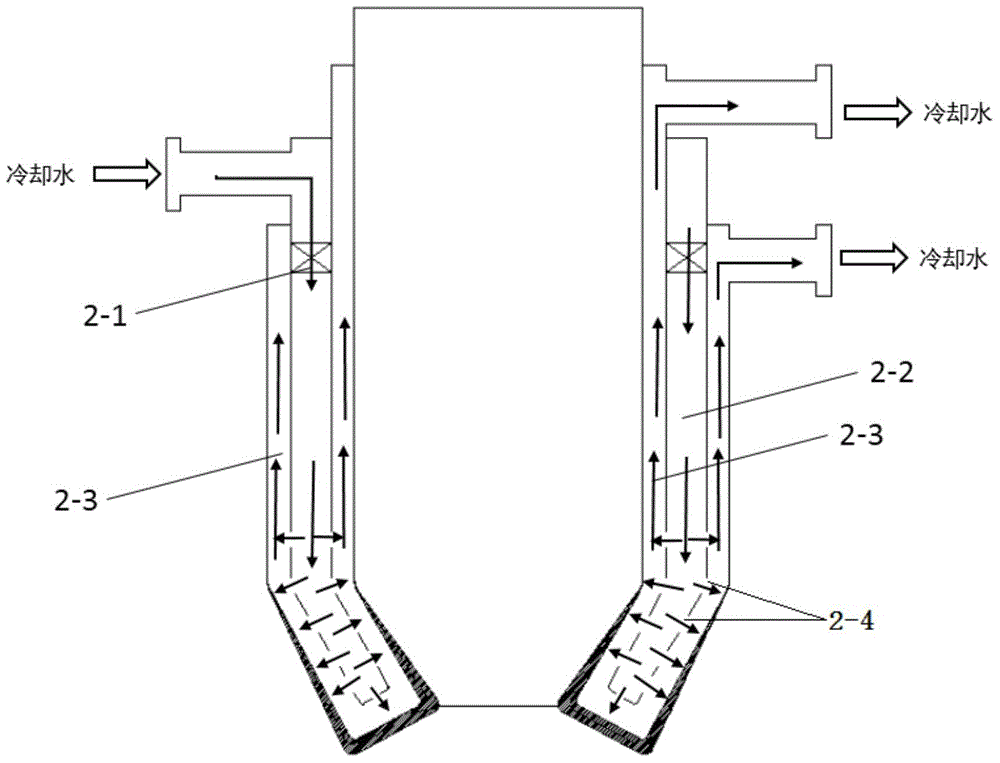

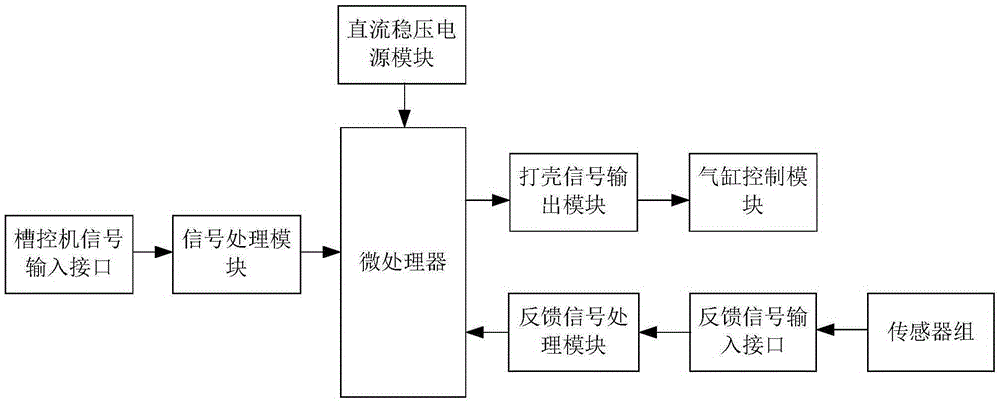

Intelligent shell beating control system for aluminum electrolysis

The invention discloses an intelligent shell beating control system for aluminum electrolysis. The intelligent shell beating control system is characterized by being mainly composed of a microprocessor, a power module, a signal processing module, a shell beating signal output module, a feedback signal processing module, a tank control system signal input interface, an air cylinder control module and a sensor set, wherein the power module, the signal processing module, the shell beating signal output module and the feedback signal processing module are connected with the microprocessor, the tank control system signal input interface is connected with the signal processing module, the air cylinder control module is connected with the shell beating signal output module, and the sensor set is connected with the feedback signal processing module; and the signal processing module is composed of a frequency selecting circuit, a lowpass filtering circuit connected with the frequency selecting circuit, and a two-stage amplifier circuit connected with the frequency selecting circuit and the lowpass filtering circuit at the same time. Whether hammer heads break shell faces or not is judged by detecting shell beating feedback signals of the hammer heads, and the shell beating process is not the blind full-stroke state any more. When the shell faces are broken, the hammer heads are controlled to be lifted rapidly and disengage from an electrolytic cell, the heating time of the hammer heads is shortened, the hammer heads are prevented from being ablated and damaged, and the service life of the system is prolonged.

Owner:SICHUAN HUASUO AUTOMATION INFORMATION ENGCO

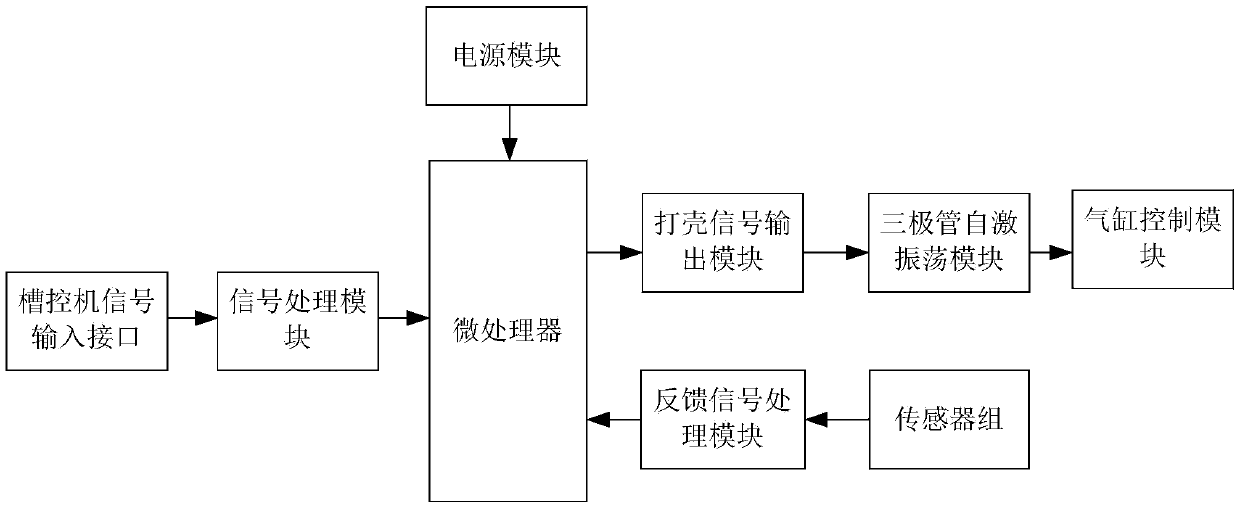

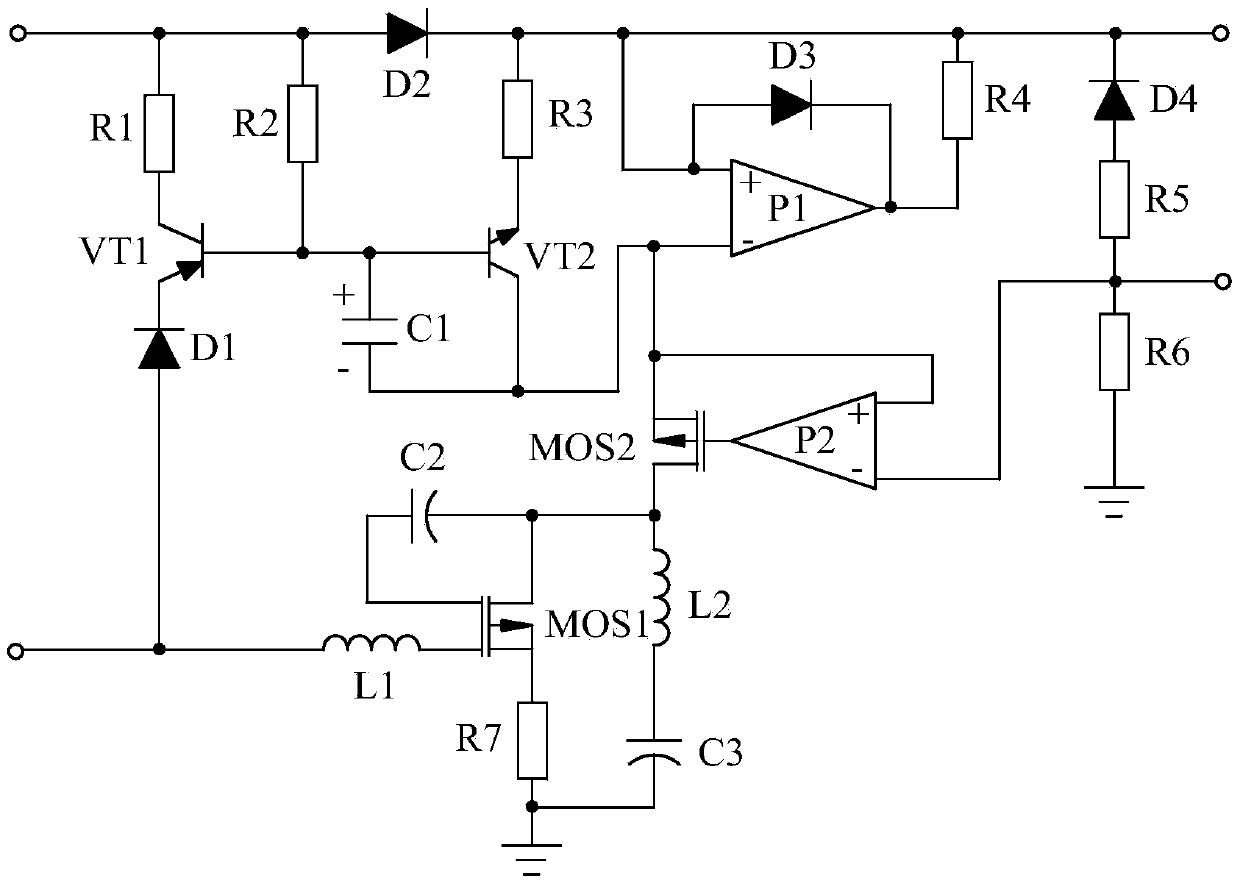

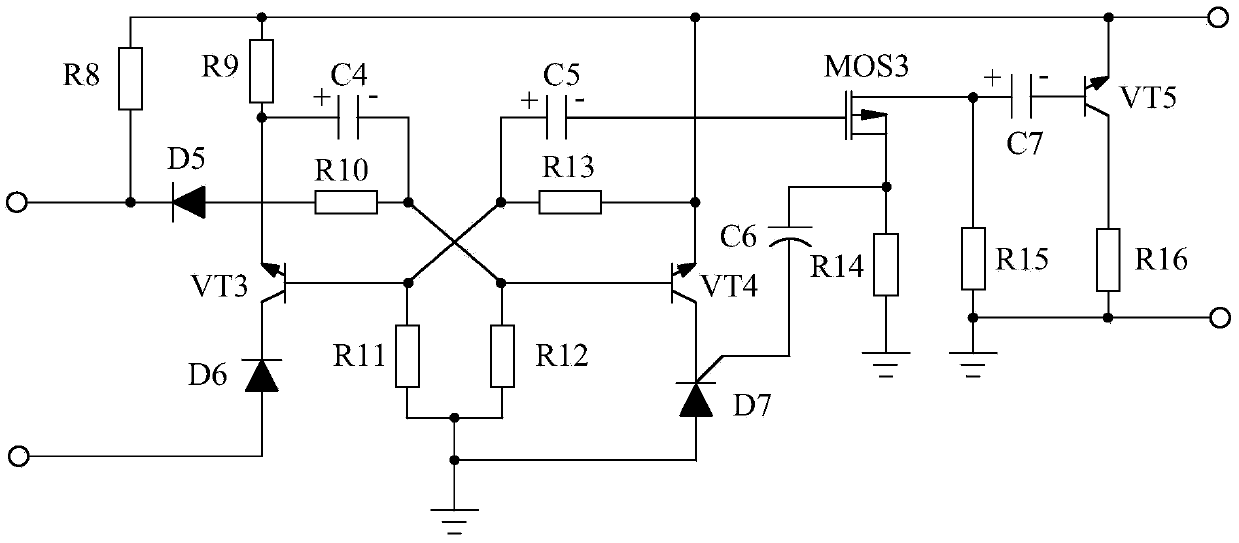

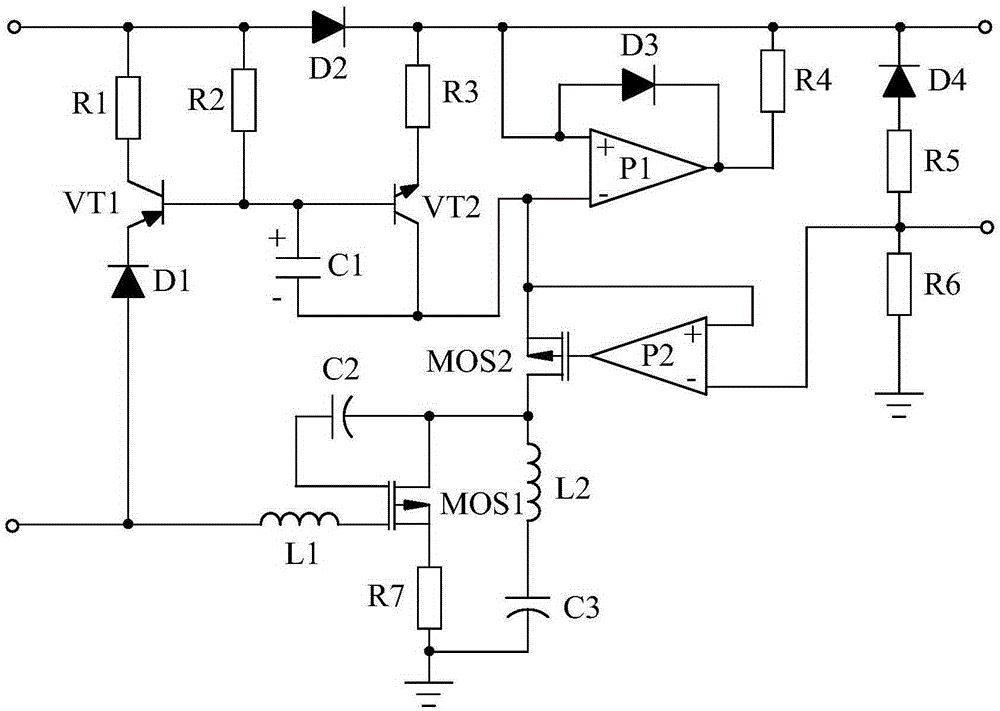

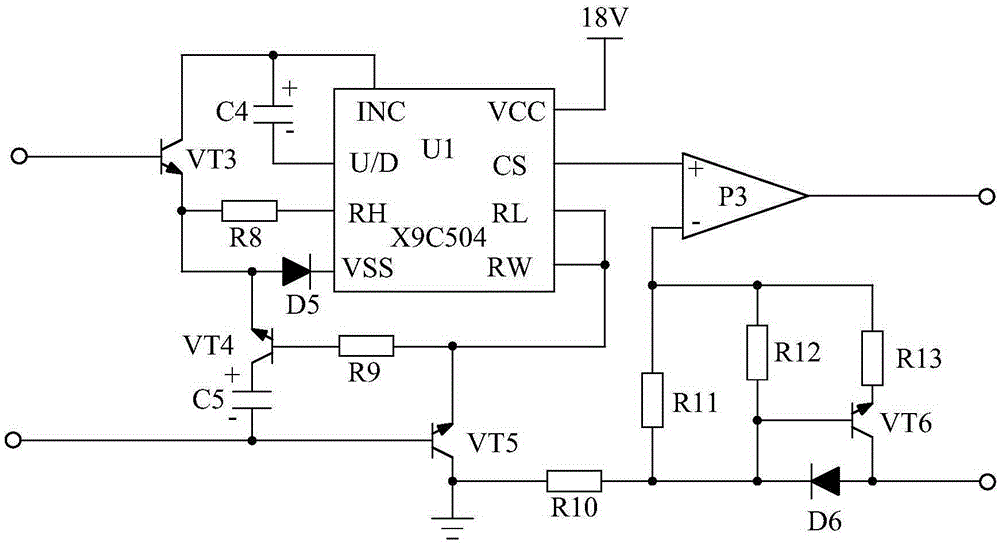

Intelligent shell breaking control system for aluminum electrolysis based on triode self-excited oscillating circuit

The invention discloses an intelligent shell breaking control system for aluminum electrolysis based on a triode self-excited oscillating circuit. The intelligent shell breaking control system is mainly composed of an air cylinder control module, a microprocessor, a power module, a signal processing module, a shell breaking signal output module, a feedback signal processing module, a tank control machine signal input interface and a sensor set, wherein the power module, the signal processing module, the shell breaking signal output module and the feedback signal processing module are connected with the microprocessor, the tank control machine signal input interface is connected with the signal processing module, and the sensor set is connected with the feedback signal processing module. The intelligent shell breaking control system is characterized in that a triode self-excited oscillating module is connected between the shell breaking signal output module and the air cylinder control module in series, and the triode self-excited oscillating module is composed of an oscillating circuit and a compensation circuit connected with the oscillating circuit. According to the intelligent shell breaking control system for aluminum electrolysis, an air cylinder can be controlled more accurately through the triode self-excited oscillating module, and the phenomenon that a hammer is immersed in an electrolyte for a long time, and consequently a hourglass head is generated is avoided.

Owner:SICHUAN HUASUO AUTOMATION INFORMATION ENGCO

Gasifying agent and water mixing atomizing nozzle and atomizing method thereof

InactiveCN111515041AAvoid ablative damageLarge specific surface areaConstructionsCoal gasificationCoalEngineering

The invention discloses a gasifying agent and water mixing atomizing nozzle and an atomizing method thereof. The atomizing nozzle comprises a nozzle body with a central through hole, a central spray pipe is arranged in the central through hole, the tail end of the central spray pipe is contracted into a conical spray port, an annulus channel is arranged between the nozzle body and the central spray pipe, the central spray pipe is surrounded by the annulus channel, a guide sleeve is connected with the tail end of the annulus channel, and a mixing chamber is connected with the tail end of the guide sleeve. According to the gasifying agent and water mixing atomizing nozzle and the atomizing method thereof, by enhancing the water atomization effect and increasing the specific surface area of liquid drop, the phase interface area with coal heat and mass transfer is increased, and the combustion and gasification reaction efficiency is improved; and since the gasification agent and atomized water are simultaneously sprayed into the coal seam combustion and gasification reaction working face, the direct contact reaction with the gasification working face is achieved, the water injection volume is reduced, and the thermal efficiency is improved.

Owner:北京国利衡清洁能源科技(集团)有限公司

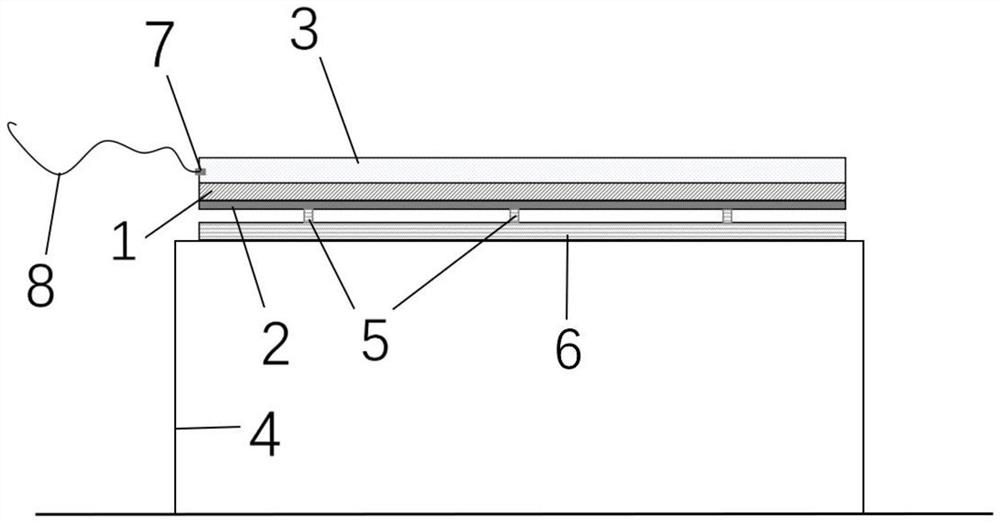

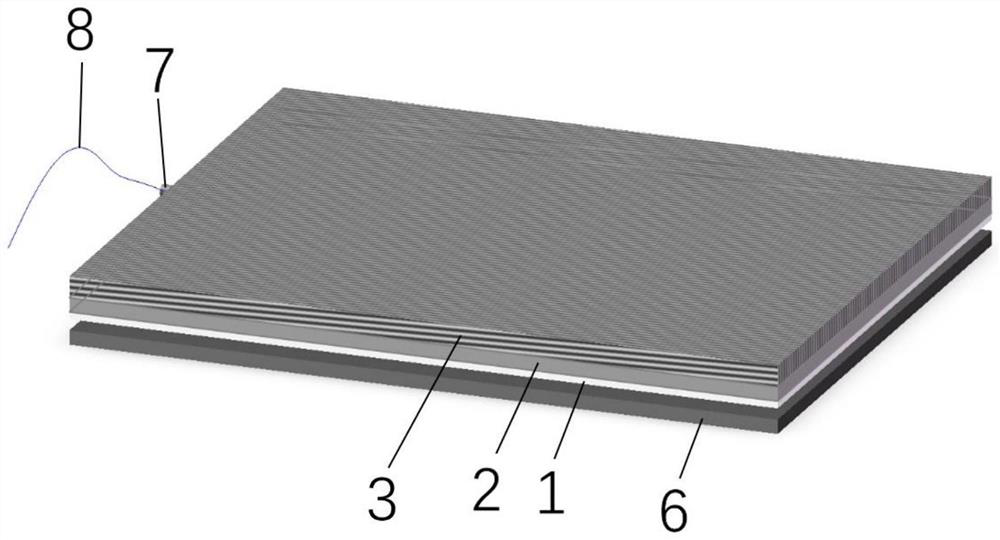

Preparation method of thin multi-layer explosive welding composite board in vacuum environment

InactiveCN114131172AAvoid ablative damageExplosive Freedom of ChoiceNon-electric welding apparatusDetonatorTEX-explosive

The invention provides a method for preparing a thin composite layer explosive welding composite board in a vacuum environment, which comprises the following steps of: putting an explosive welding device in a vacuum device through a cutting board, arranging a base plate, a plurality of support columns and a thin composite board from bottom to top, and tightly attaching a buffer plate to the upper edge of the thin composite board. Explosive is laid on the buffer plate, a detonator is connected in the buffer plate, and a detonating cord is connected outside the vacuum device through the vacuum device. And the explosive welding device is detonated in the vacuum environment, the thin composite plate is welded to the base plate through the buffer plate under the high pressure of explosive explosion, and preparation of the composite plate is completed. Compared with a traditional preparation method, the method for preparing the composite plate through thin composite layer explosive welding is higher in success rate, and ablation damage to the surface of the thin composite plate caused by direct contact of explosives and the thin composite plate can be effectively prevented; the conditions that bulges are caused by air, brittle intermetallic compounds are generated, the bonding strength is low and even welding fails are avoided; the detonation velocity of the explosive is selected more freely, and the operability is higher; and the influence of vibration and noise on the surrounding environment can be obviously reduced.

Owner:ANHUI UNIV OF SCI & TECH

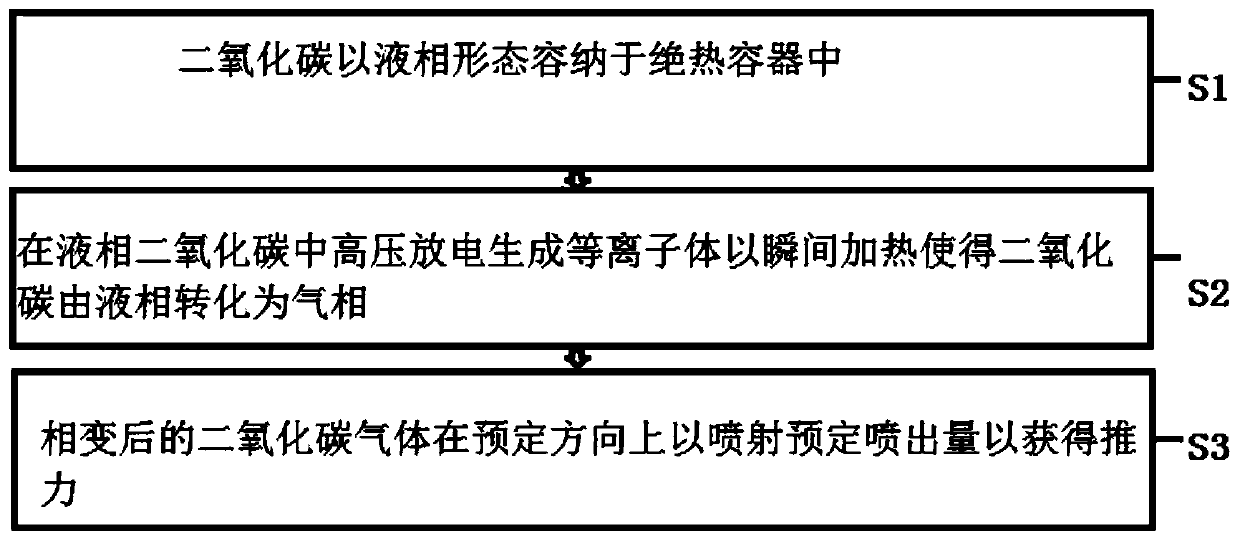

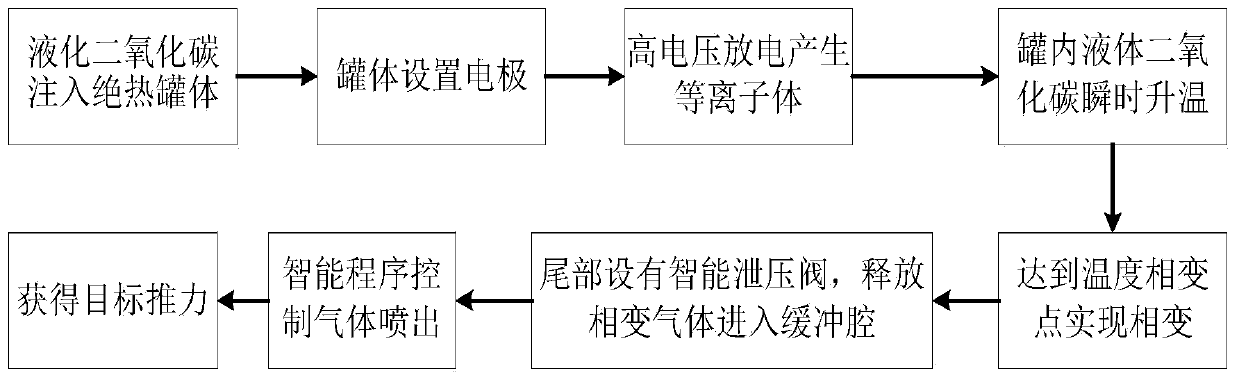

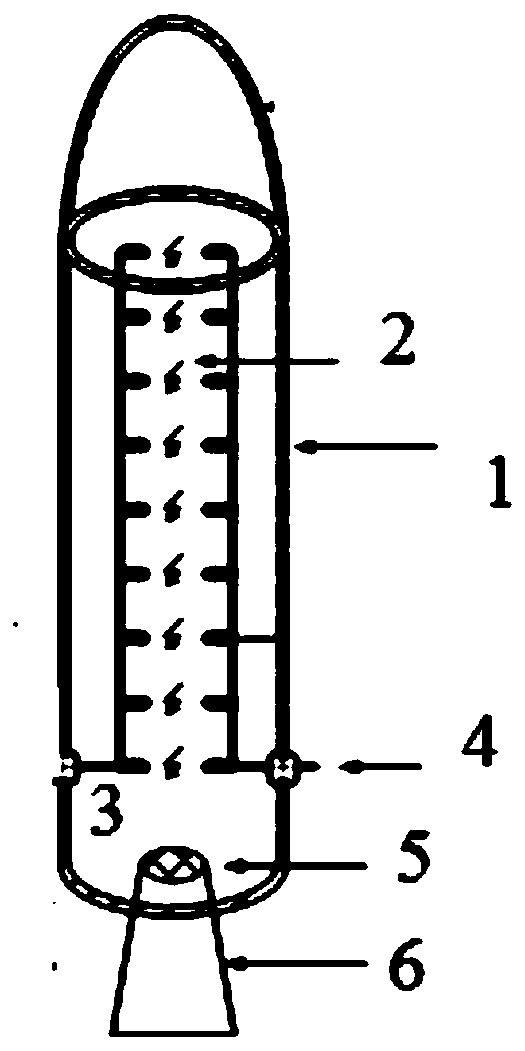

Liquid-phase carbon dioxide phase change propelling method and propelling device based on high-voltage discharge

PendingCN111003219APrecise controlAvoid ablative damageCosmonautic vehiclesCosmonautic propulsion system apparatusCarbon dioxideFluid phase

The invention discloses a propelling method and a propelling device for liquid-phase carbon dioxide phase change based on high-voltage discharge. The method comprises the following steps that carbon dioxide is contained in a heat insulation container in a liquid phase form, high-voltage discharge is carried out in the liquid-phase carbon dioxide to generate plasma to be instantly heated so that the carbon dioxide can be converted into a gas phase from a liquid phase, and carbon dioxide gas obtained after phase change is jetted by a preset jetting amount in the preset direction to obtain thrust.

Owner:XI AN JIAOTONG UNIV

A new gasification process burner with jet impingement cooling

ActiveCN103937553BGuaranteed uptimeExtended service lifeGranular/pulverulent flues gasificationJet flowInlet channel

The invention discloses a novel jet impingement cooling gasification technology burner. The novel jet impingement cooling gasification technology burner comprises a central gasifying agent channel, fuel channels, outer gasifying agent channels, and cooling water channels; the central gasifying agent channel is coaxially sieved by the fuel channels and the outer gasifying agent channels successively; the cooling water channels are arranged between the central gasifying agent channel and the fuel channels, between the fuel channels and the outer gasifying agent channels, and on the outsides of the outer gasifying agent channels; the cooling water channels are composed of water inlet channels and water return channels; cooling water uniform distribution devices are arranged in the water inlet channels; the water inlet channels and the water return channels are communicated via a plurality of circular holes which are closely arranged on the lower channel parts of the water inlet channels; high pressure cooling water is delivered into the water inlet channels, and then the walls of the water return channels are impinged by the high pressure cooling water through the plurality of circular holes which are closely arranged on the lower channel parts of the water inlet channels in a jet flow manner, so that high efficient cooling of the walls of the water return channels is realized; and then the high pressure cooling water is delivered to water outlets of the cooling water channels via the water return channels. The novel jet impingement cooling gasification technology burner is capable of solving problems of existing gasification technology burners that cooling effect is poor, and service life is relatively short.

Owner:XI AN JIAOTONG UNIV

Intelligent shell breaking control system for aluminum electrolysis based on direct current stabilized power supply

The invention discloses an intelligent shell breaking control system for aluminum electrolysis based on direct current stabilized power supply. The intelligent shell breaking control system is mainly composed of a microprocessor, a direct current stabilized power supply module, a signal processing module, a shell breaking signal output module, a feedback signal processing module, a slot control machine signal input interface, an air cylinder control module, a feedback signal input interface and a sensor set, wherein the direct current stabilized power supply module, the signal processing module, the shell breaking signal output module and the feedback signal processing module are connected with the microprocessor, the slot control machine signal input interface is connected with the signal processing module, the air cylinder control module is connected with the shell breaking signal output module, the feedback signal input interface is connected with the feedback signal processing module, and the sensor set is connected with the feedback signal input interface. The intelligent shell breaking control system is characterized in that the direct current stabilized power supply module is composed of a diode D8, a transformer T, an inductance coil L3 arranged on the primary side of the transformer T, an inductance coil L4, an inductance coil L5 and the like, and the inductance coil L4 and the inductance coil L5 are arranged on the secondary side of the transformer T. The direct current stabilized power supply module is used for providing working power supply and is high in stability and low in ripple coefficient and energy consumption, accordingly, the energy consumption of the intelligent shell breaking control system is reduced, and the stability of the intelligent shell breaking control system is improved.

Owner:SICHUAN HUASUO AUTOMATION INFORMATION ENGCO

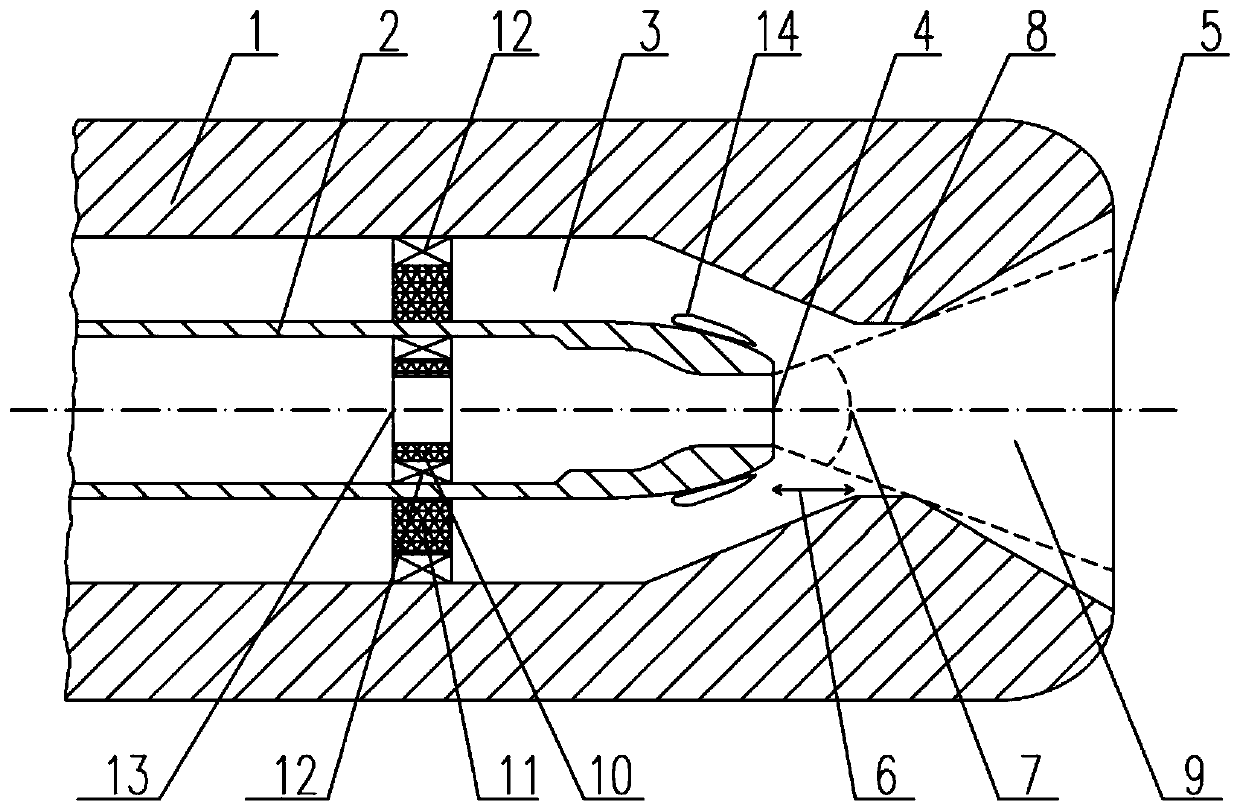

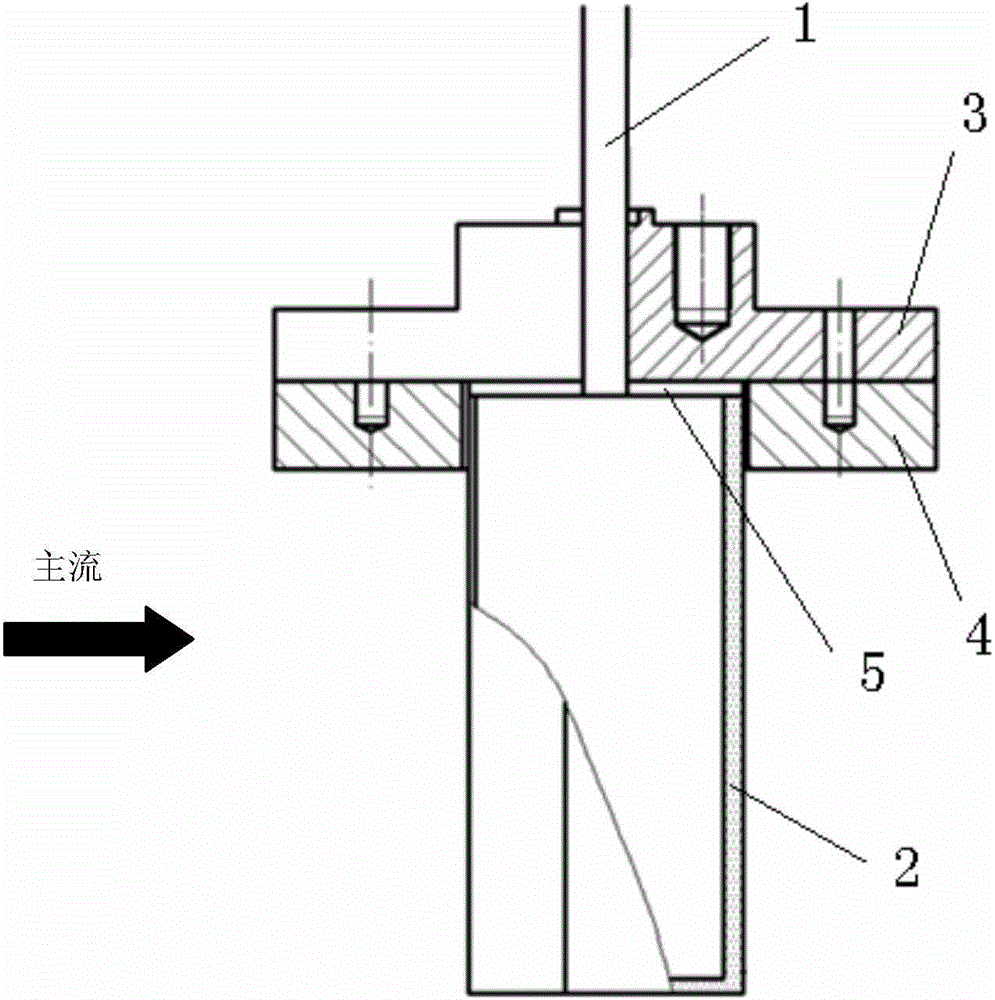

Heat protection method for injection support plate of scramjet engine by utilizing sweat and impingement cooling

ActiveCN103615741BReduce the temperatureAvoid ablative damageContinuous combustion chamberPorous mediumEngineering

The invention relates to a heat protection method for an injection support plate of a scramjet engine by utilizing sweat and impingement cooling. The method includes the following steps that (1) a high-temperature-resistant material is used for making the injection support plate of a microporous structure, a supporting rib is arranged in the injection support plate and partitions the same into a front cavity and a rear cavity, impingement pores communicated with the front and rear cavities are formed in the supporting rib, and a fuel pipe of the scramjet engine is communicated with the rear cavity of the injection support plate; (2) by the process that fuel seeps out of pores of the injection support plate of the microporous structure, convection heat transfer is carried out forcedly to remove heat on the surface of the injection support plate, and the fuel seeps out of the surface of the injection support plate to form a film layer so as to block heat transfer of the mainstream to the injection support plate; (3) the fuel is injected from the rear cavity to the inner surface of the front cavity via the impingement pores in the supporting rib so as to perform convection heat transfer with the inner surface of the front cavity, and strength of the injection support plate is enhanced by the aid of the supporting rib in the injection support plate. Heat protection effect on the injection support plate is realized by combining the concept of impingement cooling and utilizing the fuel as a cooling agent according to porous medium characteristics, and the method can be widely applied to heat protection of injection support plates of scramjet engines in various Mach working ranges.

Owner:TSINGHUA UNIV

Regeneration protection system and vehicle

InactiveCN113339114ASpeed up coolingAvoid ablative damageInternal combustion piston enginesExhaust apparatusNitrogen dioxideExhaust fumes

The invention relates to a regeneration protection system and a vehicle. The regeneration protection system comprises an engine, an exhaust pipeline, a diesel particle complementing and collecting device, an oxidation catalyst, an ammonia gas supply unit and an electronic control unit, wherein one end of the exhaust pipeline communicates with the engine; the diesel particle complementing and collecting device is arranged on the exhaust pipeline and communicates with the exhaust pipeline; the oxidation catalyst is arranged on the exhaust pipeline between the engine and the diesel particle complementing and collecting device and communicates with the exhaust pipeline; the ammonia gas supply unit communicates with the exhaust pipeline between the engine and the oxidation catalyst; and the electronic control unit is in communication connection with the ammonia gas supply unit, and the electronic control unit is used for controlling the ammonia gas supply unit to supply ammonia gas to the exhaust pipeline. According to the regeneration protection system, the ammonia gas supply unit is controlled to spray ammonia gas into the oxidation catalyst, oxygen and nitrogen dioxide required by the regeneration reaction in waste gas are consumed, and the oxidation reaction of carbon particles is reduced or even stopped from the perspective of a regeneration mechanism. In this way, the cooling speed of the diesel particle complementing and collecting device is increased, and therefore the diesel particle complementing and collecting device is effectively prevented from being ablated and damaged.

Owner:FAW JIEFANG AUTOMOTIVE CO

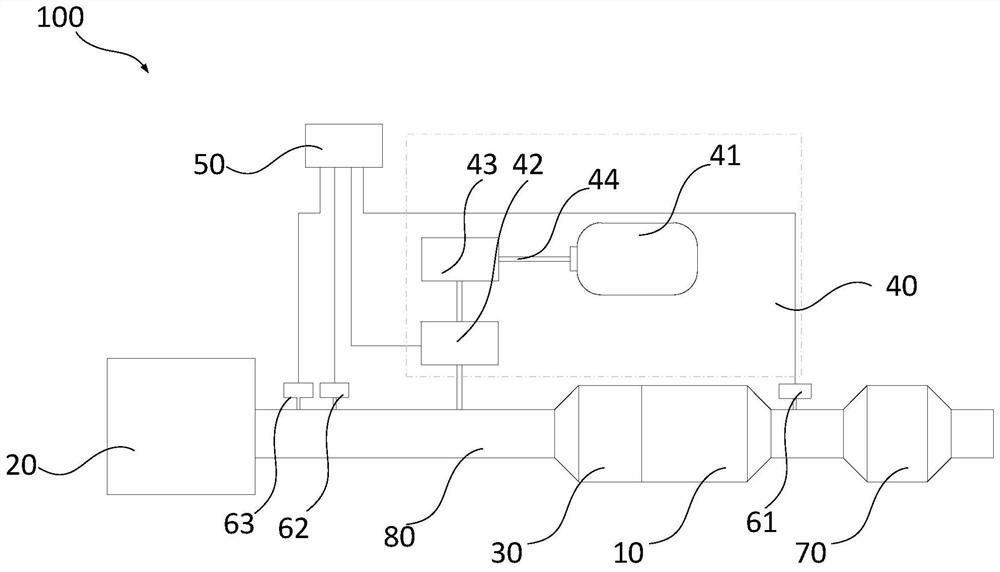

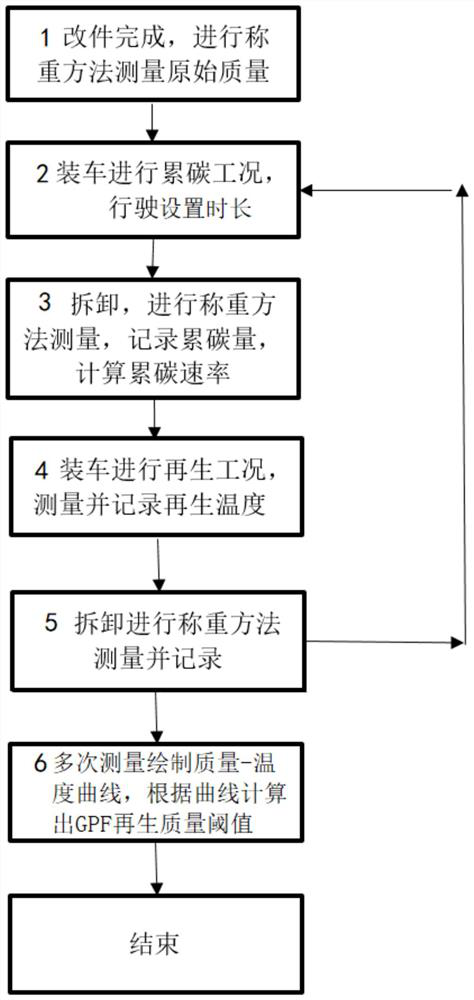

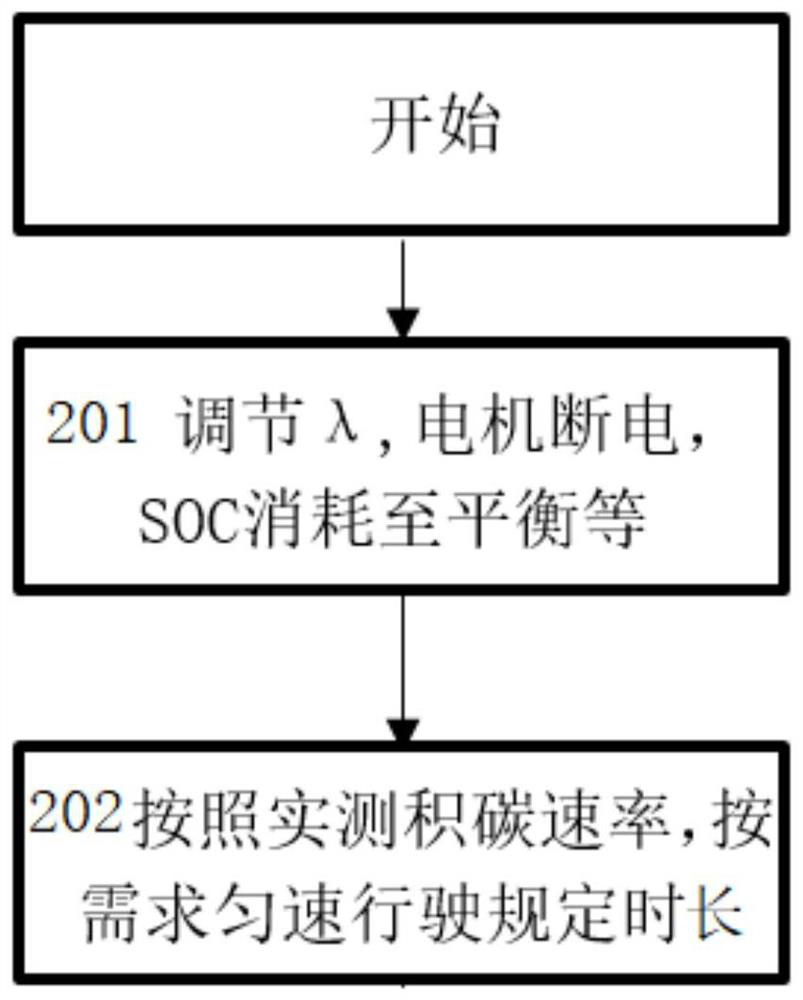

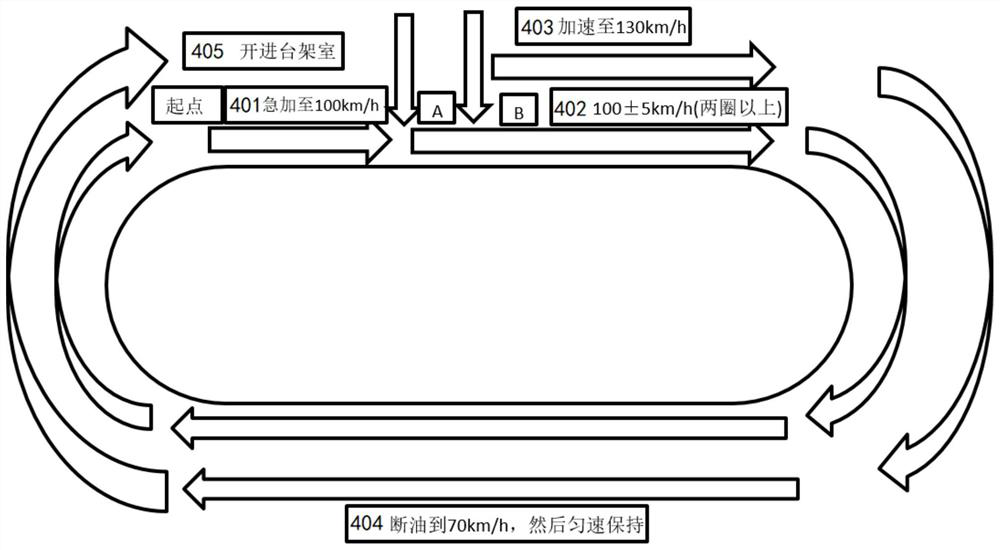

A Calculation Method of Hybrid Vehicle GPF Regeneration Quality Threshold

ActiveCN111911268BAvoid ablative damageElectrical controlDrawing from basic elementsThermodynamicsTemperature curve

The invention relates to the technical field of automobile control, in particular to a method for calculating a GPF regeneration quality threshold of a hybrid vehicle. Perform the carbon accumulation process; measure the mass m11 of the GPF; perform the regeneration process; measure the mass m12 of the GPF, and obtain the temperature of the GPF as the GPF regeneration temperature T1; calculate the difference between the mass m11 of the GPF and the mass m12 of the GPF, and obtain the GPF regeneration accumulation Carbon mass m1; repeat the above operations until multiple sample data are obtained; draw a transverse mass-temperature curve diagram; obtain the carbon accumulation mass corresponding to the critical temperature of CPF according to the mass-temperature curve diagram, and use it as the GPF regeneration quality threshold. GPF ablation damage caused by temperature increases to the GPF limit can be avoided.

Owner:DONGFENG MOTOR CORP HUBEI

Thermal protection method for scramjet engine fuel injection supporting plate by utilization of transpiration cooling

ActiveCN103672966BReduce the temperatureAvoid ablative damageContinuous combustion chamberRamjetEngineering

Owner:TSINGHUA UNIV

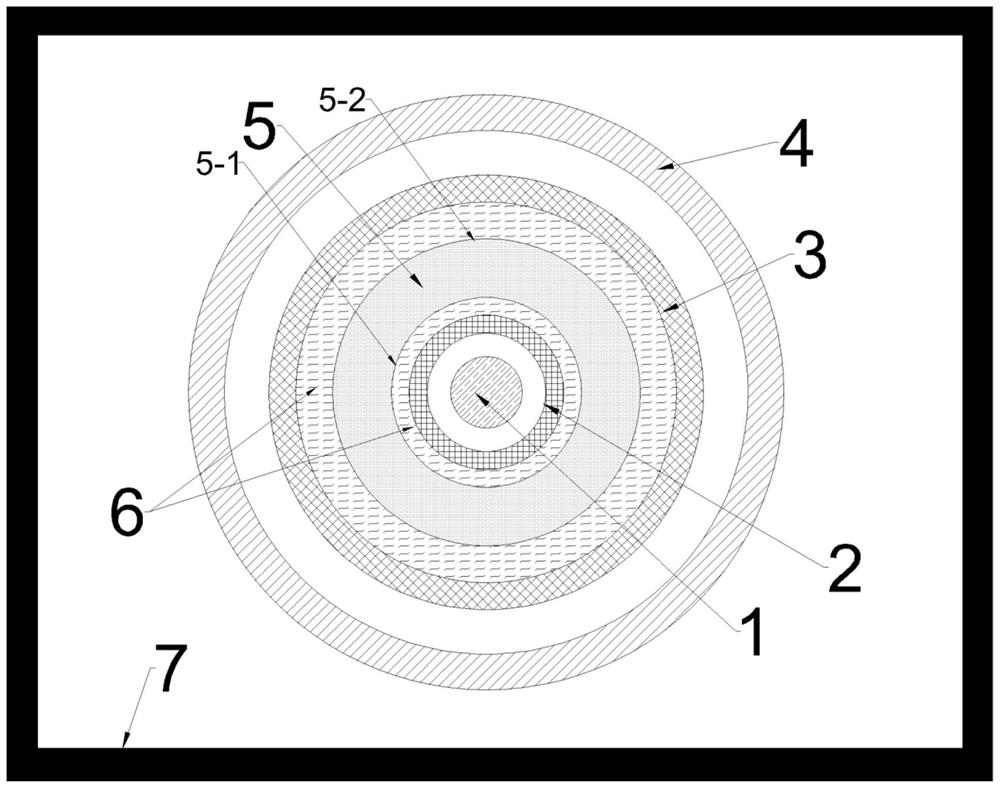

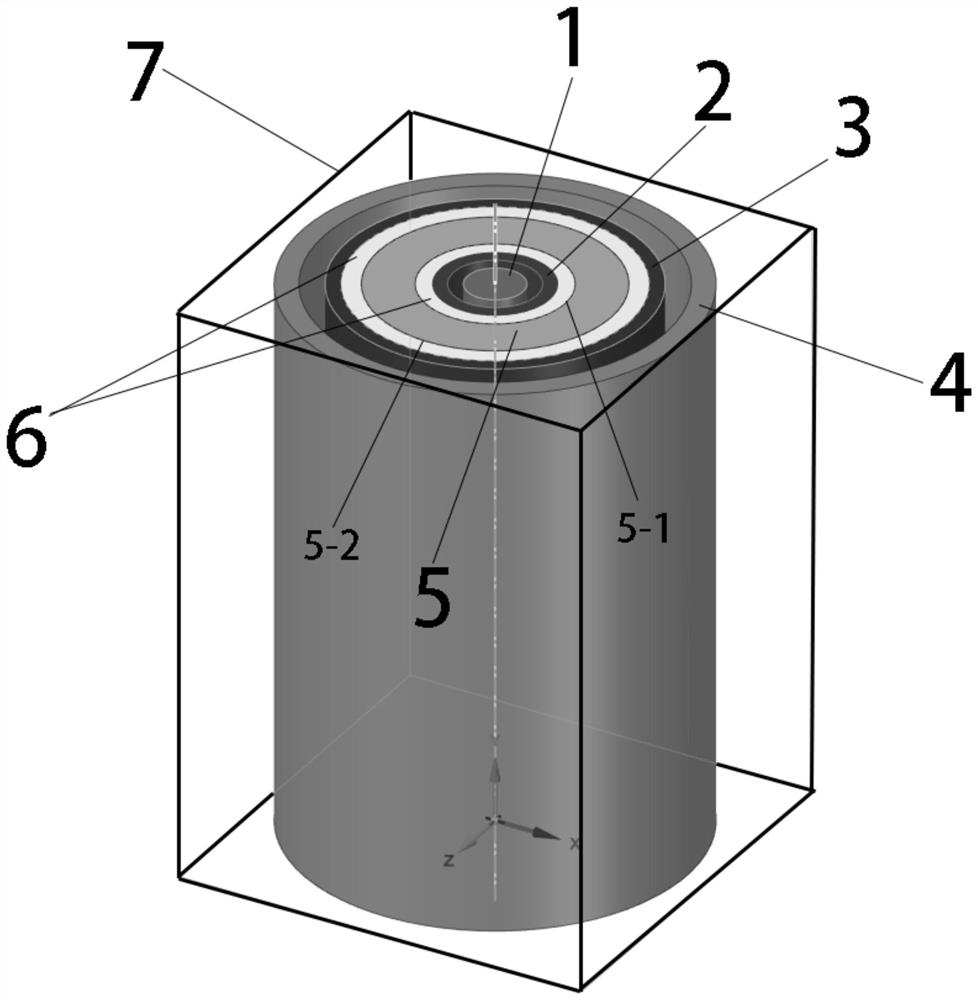

Method for preparing high-efficiency explosive composite pipe based on water pressure in local vacuum environment

InactiveCN114160950AAddresses susceptibility to burn damageSusceptible to burn damage avoidNon-electric welding apparatusDetonatorPipe

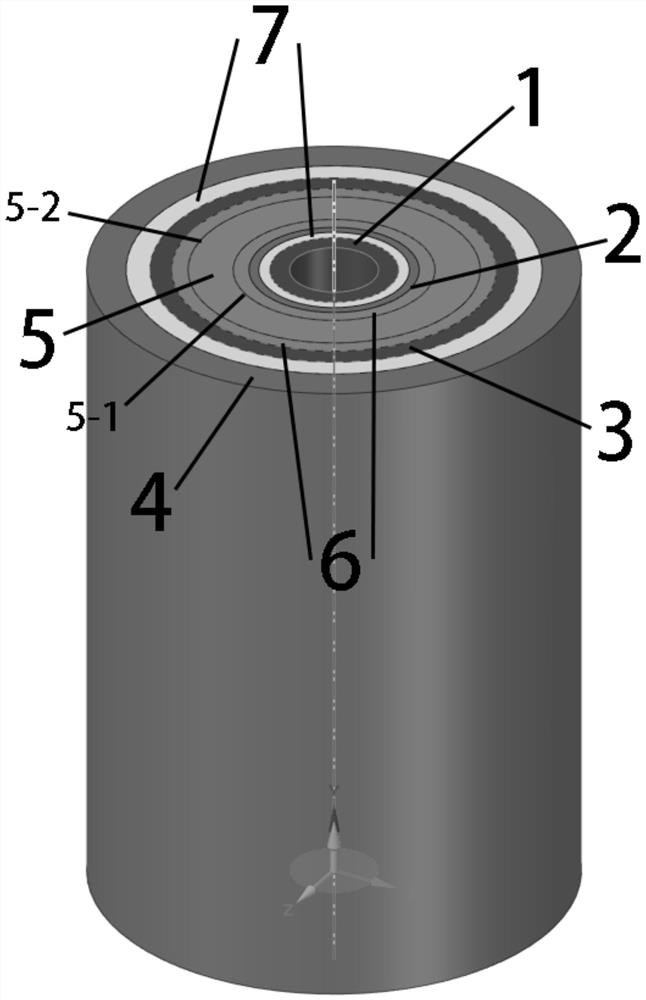

The invention provides a method for preparing an efficient explosive composite pipe based on water pressure in a local vacuum environment. The method comprises the steps that metal pipes 1 and 2, pvc pipes 5-1 and 5-2 and metal pipes 3 and 4 are coaxially arranged from inside to outside; an explosive and a detonator are filled between the pvc tubes 5-1 and 5-2 to form an explosive device; sealing two ends of gaps between the metal pipes 1 and 2 and between the metal pipes 3 and 4, and vacuumizing to construct a local vacuum environment; filling water among the metal pipe 2, the metal pipe 3 and the explosive device to construct a water environment; and the explosion device is detonated according to requirements, so that all the metal pipes are welded and combined with one another, and two groups of high-quality explosion composite pipes with different pipe diameters are obtained. According to the preparation method of the explosive composite pipe, the phenomenon that the bonding interface of the metal pipe is locally melted due to an air layer is eradicated, the utilization rate of the explosive is increased, burning damage to the surface of the metal pipe due to high temperature of the explosive is relieved, and the problem that high-quality machining of a thin-wall material cannot be achieved through a traditional method is effectively solved.

Owner:ANHUI UNIV OF SCI & TECH

A semi-automatic magnetic tile tensioning device

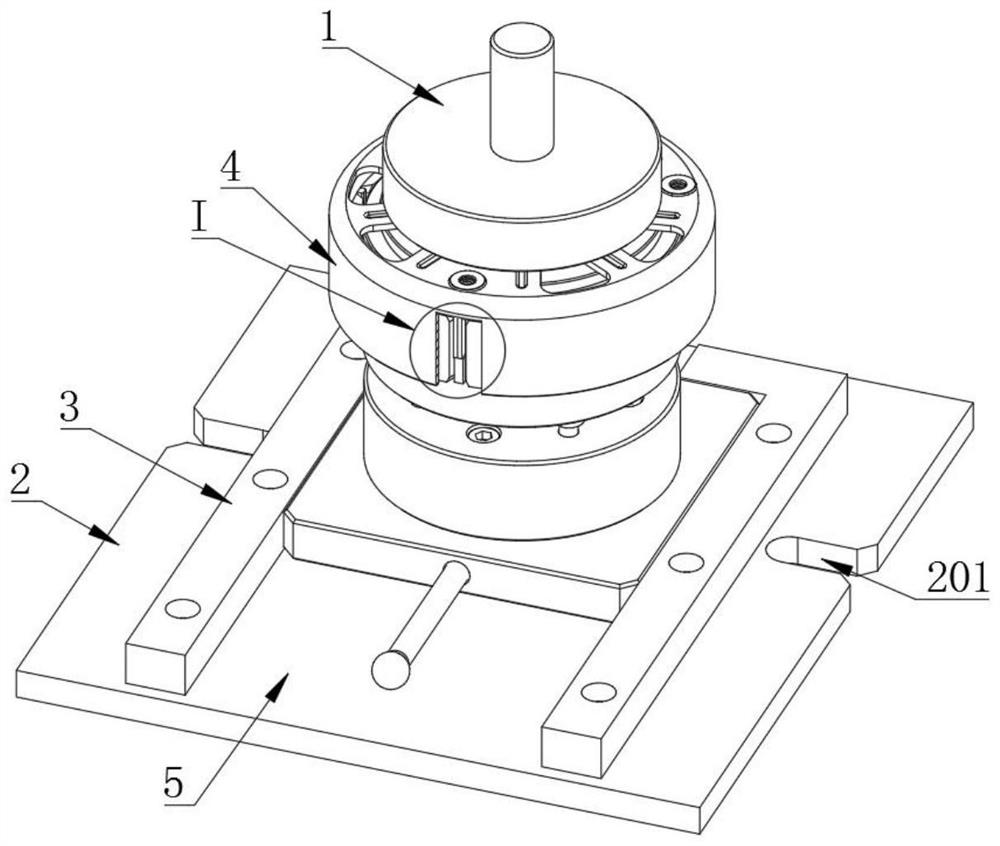

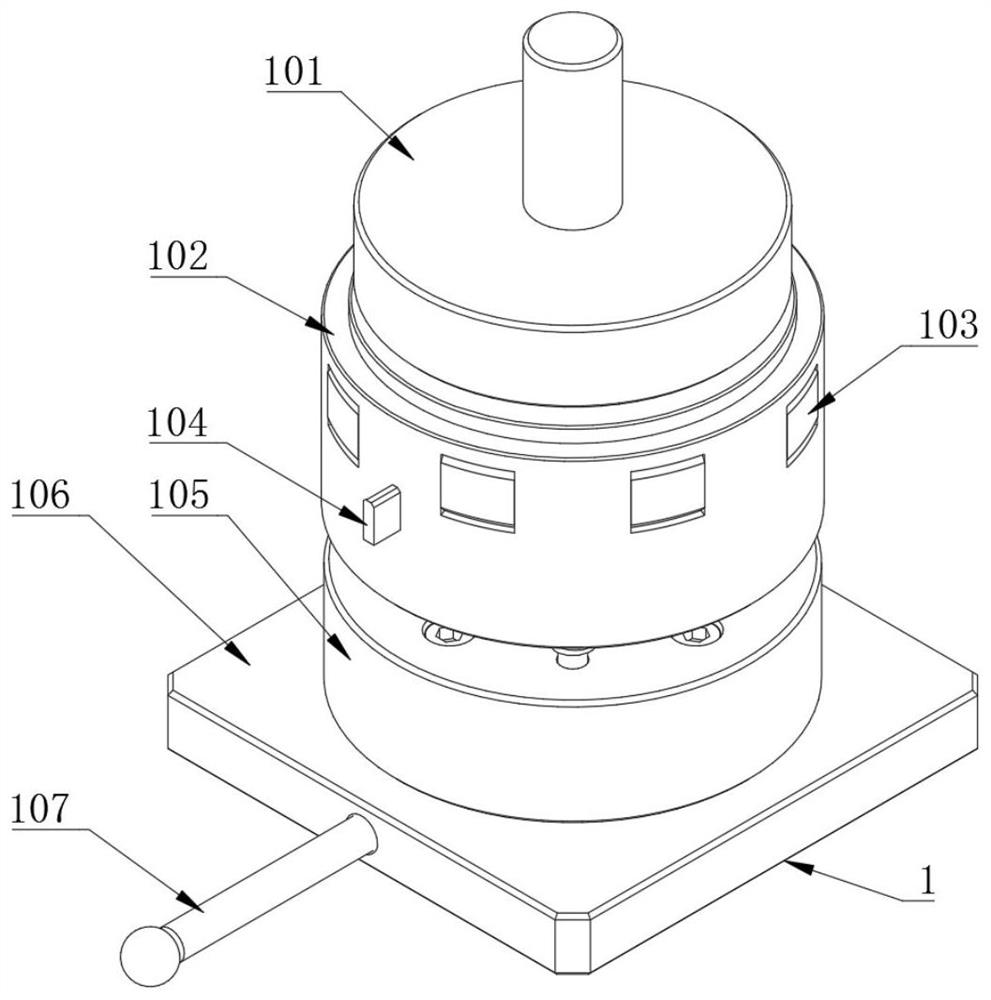

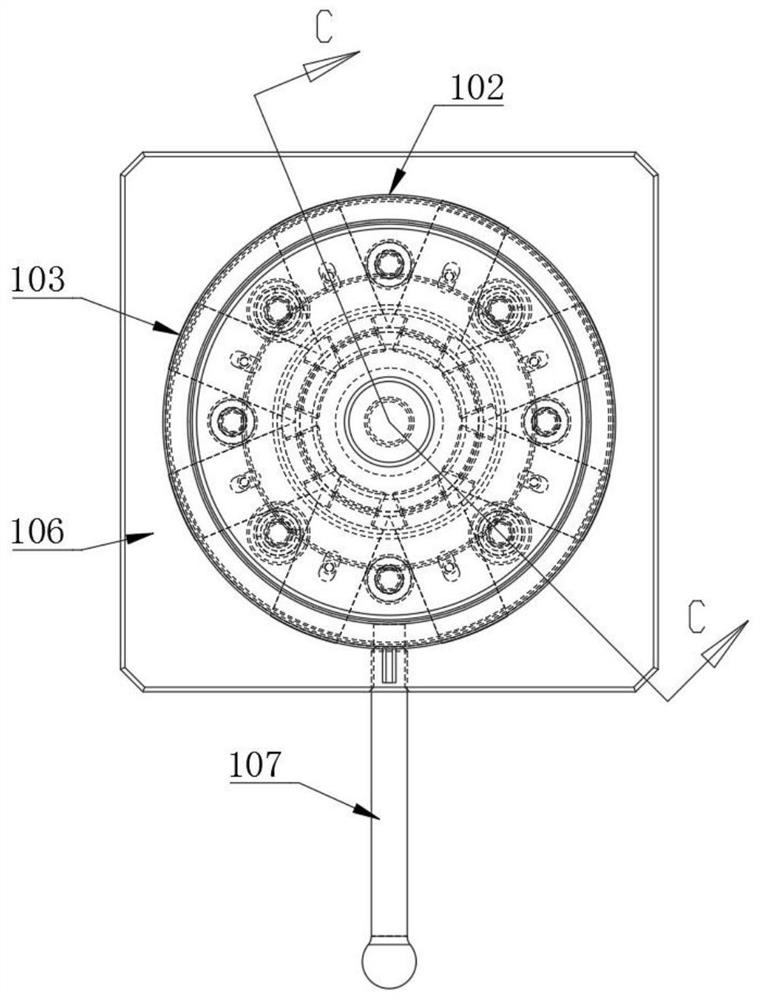

ActiveCN112953138BEasy to push toHigh bonding strengthManufacturing stator/rotor bodiesClassical mechanicsAdhesive glue

The invention discloses a semi-automatic magnetic tile tensioning device, comprising a positioning plate and a tensioning mechanism. The tensioning mechanism includes a bottom plate, a guide seat, a positioning base, a locking block, a cylindrical pin, an elastic reset device and an upper die. The seat is sleeved on the upper part of the guide seat, the upper end of the guide seat is provided with an outer conical part, the inside of the positioning base is provided with a second circular hole at a corresponding position, and the outer side wall of the upper end of the second circular hole is provided with N square holes that are evenly distributed around the circumference. A locking block is inserted into the square hole, which can be connected with the square hole to move along a radial line. The inner side of the locking block is provided with an inner conical arc surface that matches with the outer conical part. The elastic reset device is arranged on the positioning base and the guide. between seats. In the present invention, the press drives the upper die to go down, the upper die drives the workpiece and the positioning base to go down together, drives a plurality of locking blocks to move downward and outward at the same time, and tensions the corresponding magnetic tiles, which ensures the uniform thickness of the glue and improves the magnetic properties. The bonding strength of the tile can effectively avoid the phenomenon of scratching between the rotor and the stator.

Owner:JIANGXI TIANYUE AUTOMOBILE PARTS

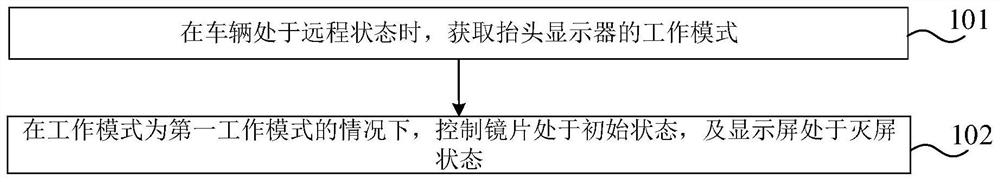

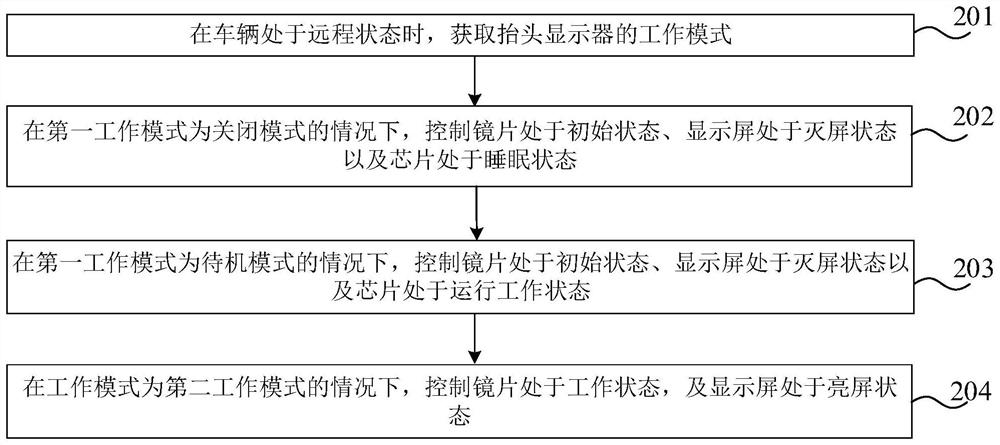

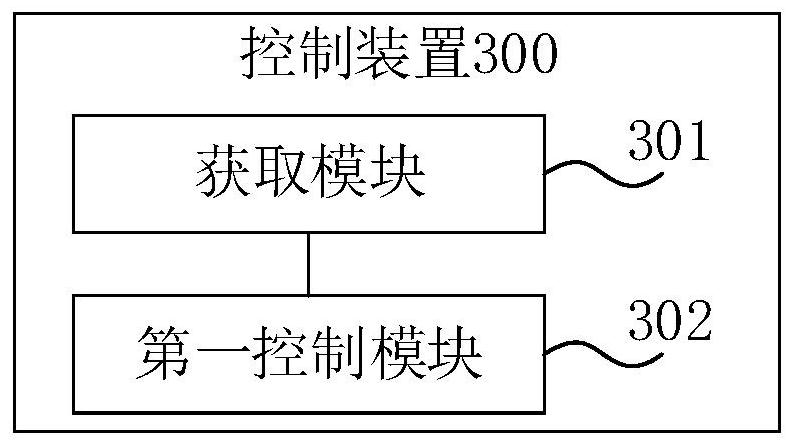

Control method and device

ActiveCN112083790AReduce consumptionAvoid being damaged by ablationDigital data processing detailsElectric/fluid circuitComputer hardwareDisplay device

The invention provides a control method and device which are applied to a vehicle with a head-up display, the head-up display comprises a lens and a display screen which are connected with each other,and the method comprises the steps that when the vehicle is in a remote state, the working mode of the head-up display is obtained; and under the condition that the working mode is a first working mode, the lens is controlled to be in an initial state and the display screen is controlled to be in a screen-off state. When the vehicle is in the remote state, the display screen of the head-up display of the vehicle is controlled to be turned off, electric energy consumption can be reduced, and the lenses are in the initial state, so that external light cannot be gathered on the display screen ofthe head-up display; and the situation that the liquid crystal screen is ablated and damaged due to over-high temperature of the display screen caused by external light is avoided.

Owner:GREAT WALL MOTOR CO LTD

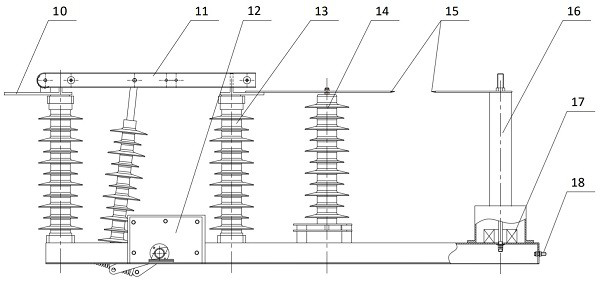

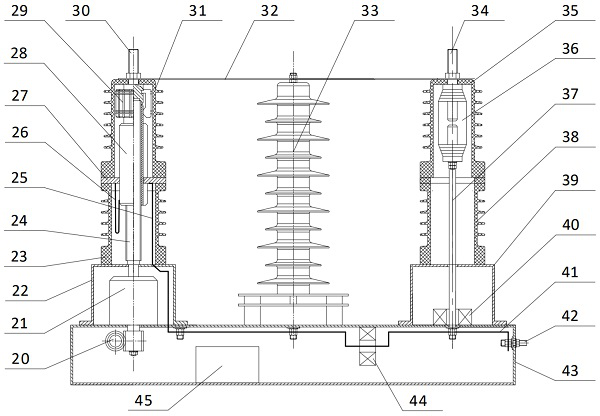

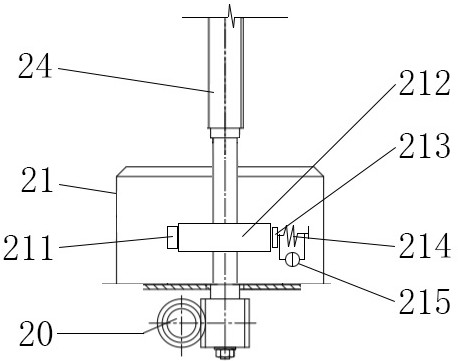

Neutral point vacuum gap grounding complete equipment for 110kV transformer

PendingCN113066646AHigh precisionSmall discreteTransformers/inductances coils/windings/connectionsElectric component structural associationOvervoltageVacuum gap

The invention relates to electric power auxiliary equipment, in particular to neutral point vacuum gap grounding complete equipment for a 110kV transformer, and the equipment comprises a machine base, an isolating switch, a lightning arrester, a vacuum gap grounding module, a common grounding copper bar, a grounding terminal, a conductive copper bar, a first current transformer and a second current transformer. The isolation switch, the lightning arrester and the vacuum gap grounding module are connected with the conductive copper bar, the transformer neutral point is connected with the conductive copper bar, the isolation switch, the lightning arrester and the vacuum gap grounding module are connected with the common grounding copper bar, the common grounding copper bar is connected with the grounding terminal, the grounding terminal is grounded, and the first current transformer is coupled with the vacuum gap grounding module; and the second current transformer is coupled with the common grounding copper bar. The invention has the substantive effects of overcoming the influence of climatic environment on gap breakdown precision, improving the accuracy of neutral point overvoltage protection, improving the safety and reliability of neutral point grounding equipment, being free of field alignment and maintenance, and saving the installation space.

Owner:HUZHOU ELECTRIC POWER SUPPLY CO OF STATE GRID ZHEJIANG ELECTRIC POWER CO LTD +1

Preparation method of explosion composite pipe rod in vacuum environment

PendingCN114433992AAvoid ablative damageImprove energy utilizationMetal working apparatusTubular articlesDetonatorMetallic materials

The invention provides a method for preparing an explosive composite pipe rod in a vacuum environment. The method comprises the following steps: coaxially arranging a metal bar 1, a metal pipe 2, a pvc pipe 5-1, a pvc pipe 5-2, a metal pipe 3 and a metal pipe 4 from inside to outside; explosive cladding explosives and detonators are filled between the pvc pipe 5-1 and the pvc pipe 5-2 to form an explosive device; filling water between the to-be-compounded pipe and the explosive device to construct a water environment; placing the to-be-compounded material, the explosive device and the water environment into a vacuum tank integrally, and vacuumizing to construct a vacuum environment; and detonating the explosive device to firmly weld the metal material to obtain two groups of high-quality explosive composite pipes and composite rods. According to the preparation method of the explosive composite pipe rod, the large-area melting phenomenon, caused by adiabatic compression of an air layer, of a material bonding surface in the welding process is eliminated, and a new thought is provided for welding work in special operation scenes such as the space environment and the underwater environment; the difficulty that high-quality machining of thin-wall materials cannot be achieved through a traditional method is effectively solved.

Owner:ANHUI UNIV OF SCI & TECH

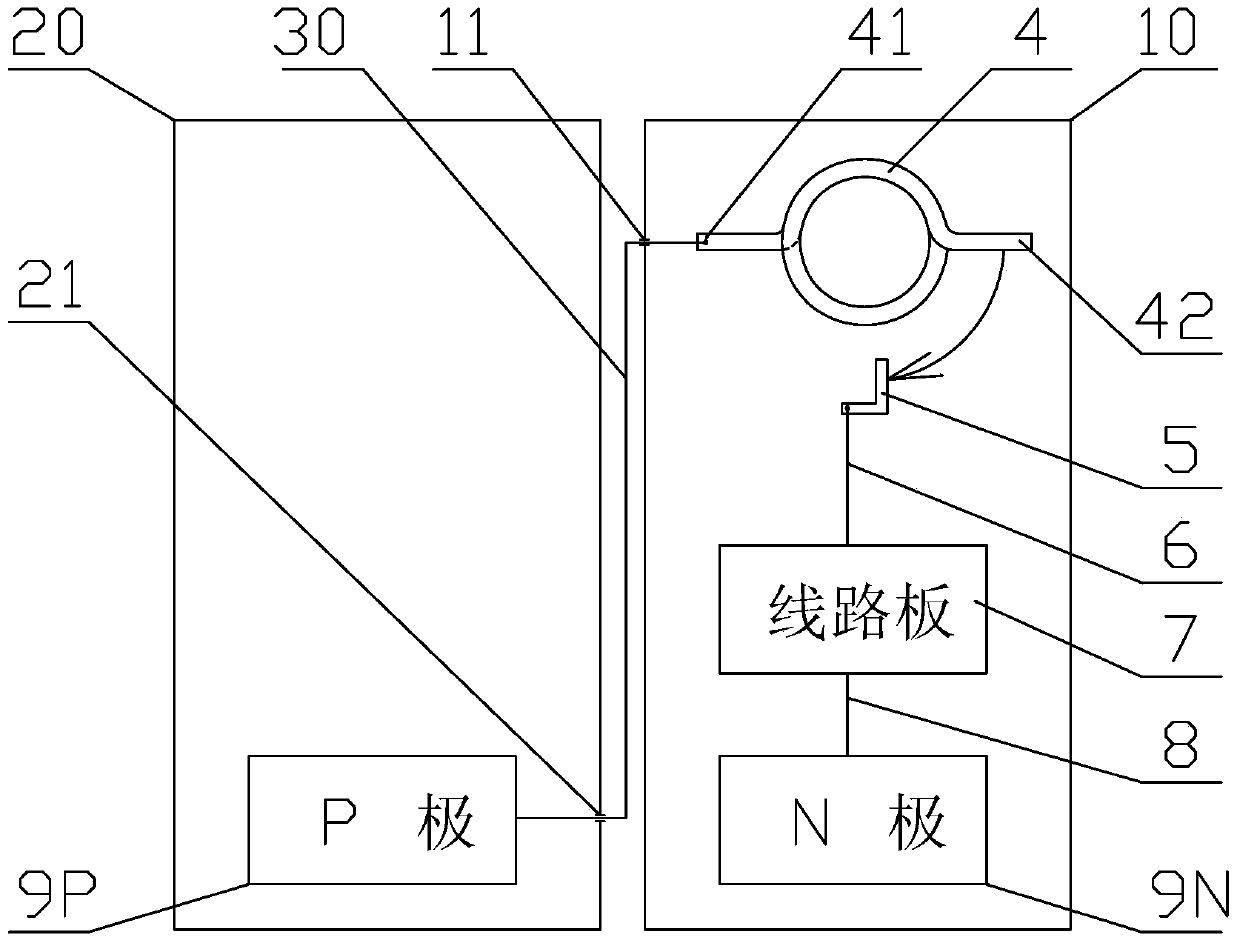

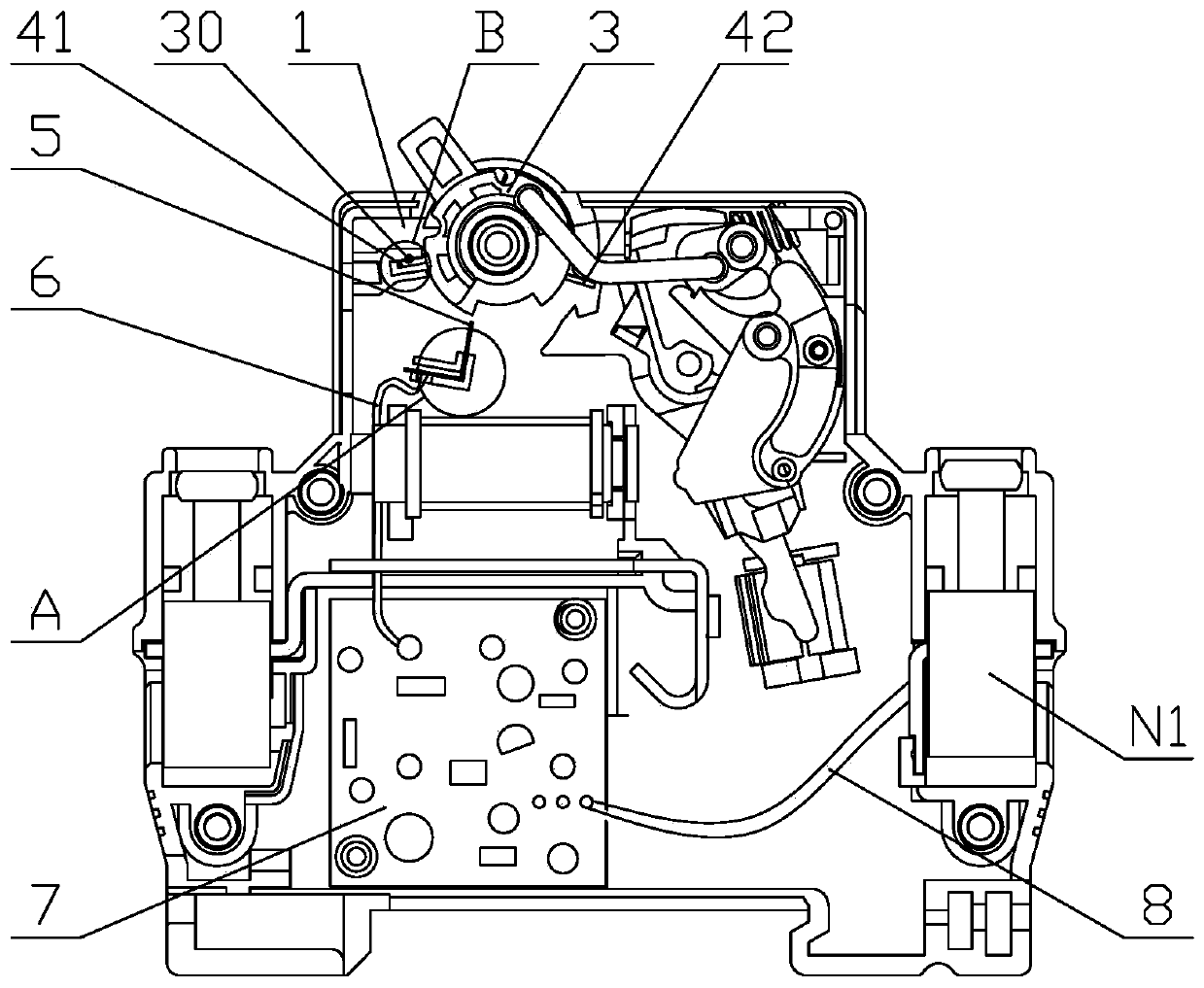

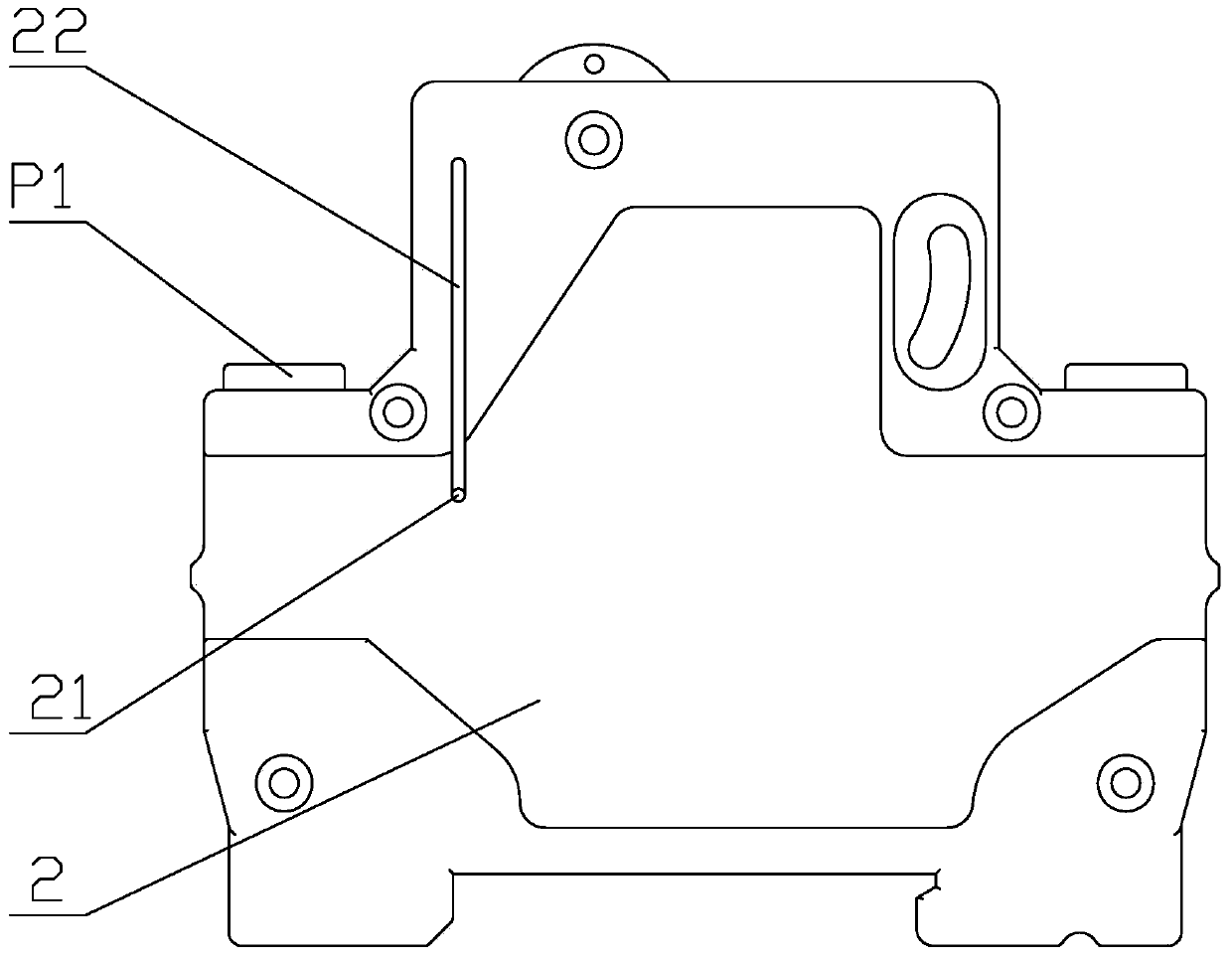

Circuit breakers and remote control miniature circuit breakers

ActiveCN106653510BAchieve conductionAvoid ablative damageProtective switch terminals/connectionsProtective switch operating/release mechanismsRemote controlControl circuit

The invention provides a circuit breaker and a remote control miniature circuit breaker. The circuit breaker comprises a handle spring used for handle resetting. The hand spring is connected in series in one circuit loop of the circuit breaker. One end of the handle spring is connected with one end of the circuit loop. The moving end of the handle spring is contacted with and separated from the other end of the circuit loop along with the closing and separating action of the handle so as to realize connection and disconnection of the circuit loop. The scheme of applying the handle spring to the circuit loop can be used for a remote control miniature circuit breaker comprising an N-pole circuit breaking unit and a P-pole circuit breaking unit, and the handle spring of the N-pole circuit breaking unit or the P-pole circuit breaking unit is connected in series in the power loop of the control circuit board of the N-pole circuit breaking unit. The moving end of the original handle spring of the circuit breaker is configured as the structure of a moving contact end which is also used for performing connection and disconnection of the line so that the structure is simple, the design is ingenious, processing and assembling are easy and the circuit breaker has great economy.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com